Concentrated intake closing device

A technology of closing device and frame, applied in valve device, valve operation/release device, valve details, etc., can solve the problems of inability to meet the use requirements of quick closing, long working stroke of the piston, restricted use occasions, etc. The effect of light weight, small working stroke and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

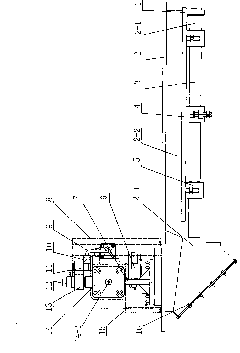

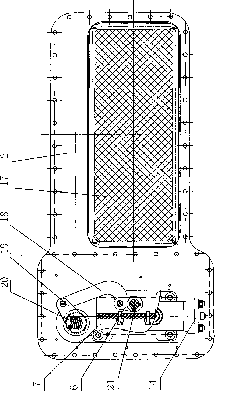

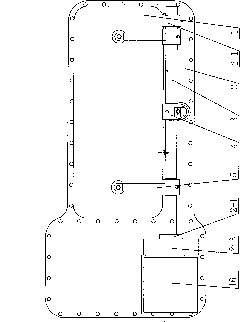

[0019] See Figure 1-7 As shown, the centralized air intake closing device of the present invention includes a valve cover 1, a driving mechanism, an auxiliary mechanism, a control mechanism and an actuator, and the frame 2 of the present invention is provided with a raised annular valve port 2-2, a shaft seat 2-1 and the gear box 2-3, the annular valve port 2-2 is rectangular, as the diameter of the annular valve port 2-2 is length×width=730×290mm, that is, the diameter equivalent is about DN500mm, the present invention The air vent of the annular valve port 2-2 has a larger ventilation rate, and the frame 2 is also fixed with a filter screen 17 inside the annular valve port 2-2.

[0020] See figure 1 , 2 , 4 to 6, the drive mechanism of the present invention is installed on one side of the frame 2, the drive mechanism includes a body 7, a swing cylinder installed on the body 7 and a connecting rod mechanism, the body 7 is provided with a cylinder hole 7- 2 and the shaft h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com