Low-carbon heating thermal-insulation floor tile

A technology of floor tiles and thermal insulation materials, applied in the field of building materials, can solve the problems of complex heating equipment and pipeline heat dissipation area, lack of antistatic and antimagnetic properties, unsatisfactory insulation and thermal insulation effects, etc., and achieve good energy saving effect and good Good heat preservation effect, heat dissipation and heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

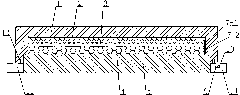

[0029] Such as figure 1 , 3 As shown in and 4, this embodiment includes an inverted concave-shaped surface plate 1 and an antistatic and anti-interference layer 2, an electric heating film 3 and a thermal insulation material layer 4 filled in the surface plate 1 in sequence. The middle part of the interference layer 2 is provided with an antistatic metal wire 7-1, and one end of the antistatic metal wire 7-1 is connected with an antistatic metal plug 9, and the left and right sides of the electric heating film 3 are symmetrically provided with electrode copper sheets 6. One end of the electrode copper sheet 6 close to the antistatic metal plug 9 is connected with a temperature-resistant waterproof power supply wire 7-2, and the end of the temperature-resistant waterproof power supply wire 7-2 near the electrode copper sheet 6 is provided with a temperature switch 8. The other end of the temperature and waterproof power supply wire 7-2 is connected with a waterproof and sealed...

Embodiment 2

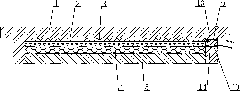

[0033] Such as figure 2 , 3 As shown in and 4, the π-shaped surface plate layer 1 of this embodiment and the antistatic and anti-interference layer 2, the electric heating film 3 and the thermal insulation material layer 4 filled in the surface plate layer 1 in turn, the antistatic and anti-interference layer 2 The middle part is provided with an antistatic metal wire 7-1, and one end of the antistatic metal wire 7-1 is connected with an antistatic metal plug 9, and the left and right sides of the electric heating film 3 are symmetrically provided with electrode copper sheets 6, and the electrode copper One end of the sheet 6 close to the antistatic metal plug 9 is connected with a temperature-resistant and waterproof power lead 7-2, and the end of the temperature-resistant and waterproof power lead 7-2 close to the electrode copper sheet 6 is provided with a temperature switch 8, and the temperature-resistant and waterproof power lead 7-2 is provided with a temperature switc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com