Pressure-sensitive anti-counterfeit label with hollowed positioning stick-on layer and manufacturing method thereof

A technology of anti-counterfeiting labels and manufacturing methods, which is applied to stamps, instruments, identification devices, etc., can solve the problems of counterfeiting and single anti-counterfeiting functions, and achieve the effect of scientific and reasonable process flow and reliable and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

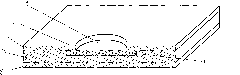

[0021] Such as figure 1 As shown, the present invention is a self-adhesive anti-counterfeiting label with a hollow positioning layer, including a film surface material layer 1, a self-adhesive layer 2 and a protective bottom layer 3, and the film surface material layer 1 is hollowed to form a Hole 4, said hole 4 is pasted and sealed with a film sheet 6 slightly larger than hole 4 by the edge 5 of the hole to form an empty positioning layer. In this way, since the film sticking sheet 6 has pits relative to the thin-film surface material layer 1, the public can better identify them through the pits, which enhances the anti-counterfeiting effect of checking.

[0022] Wherein the thin film surface material layer can be printed with anti-counterfeiting information according to actual application conditions.

Embodiment 2

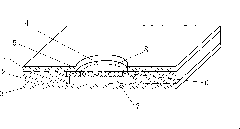

[0024] Such as figure 2 As shown, the present invention is a self-adhesive anti-counterfeiting label with a hollow positioning layer, including a film surface material layer 1, a self-adhesive layer 2 and a protective bottom layer 3, and the film surface material layer 1 is hollowed to form a Hole 4, said hole 4 is pasted and sealed with a film sheet 6 slightly larger than hole 4 through the edge 5 of the hole to form a hollow positioning layer, and said self-adhesive layer is provided with a bare empty glue-free area 7 , the surface material layer 1 is provided with a fracture creasing line 8 in the area of the bare empty glue-free area and the bare empty glue-free area 7 to form a tear check area. In order to highlight the verification function, in this embodiment, the present invention sets the above-mentioned tear-off verification area in the film sticking sheet. In this way, the public can easily tear it up and uncover it to confirm the authenticity of the product, an...

Embodiment 3

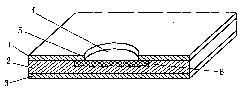

[0026] The manufacturing method of the above-mentioned self-adhesive anti-counterfeiting label with a hollow positioning layer: the first step, after the commercially available film surface material is planted as required, it is hollowed and hollowed to form a hole, and it is planted in a shape slightly larger than the above-mentioned hole. Manufacture the film, and seal the holes by bonding the film to form a hollow positioning layer.

[0027] The second step is to use the printing principle to apply positioning glue on the film surface material layer with a hollow positioning layer to form a self-adhesive layer, and thus form a bare space without glue by positioning glue in the self-adhesive layer In the film surface material layer corresponding to the bare empty glue-free zone, the tear-off inspection zone is formed by pressing the fracture indentation line with a knife die within an area range smaller than the glue-free zone.

[0028] In the third step, the above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com