Cylinder rinsing device

A technology for cleaning devices and rollers, applied in cleaning methods and utensils, cleaning methods using tools, dissolving and other directions to achieve the effects of preventing wrinkling, easy adjustment, and improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

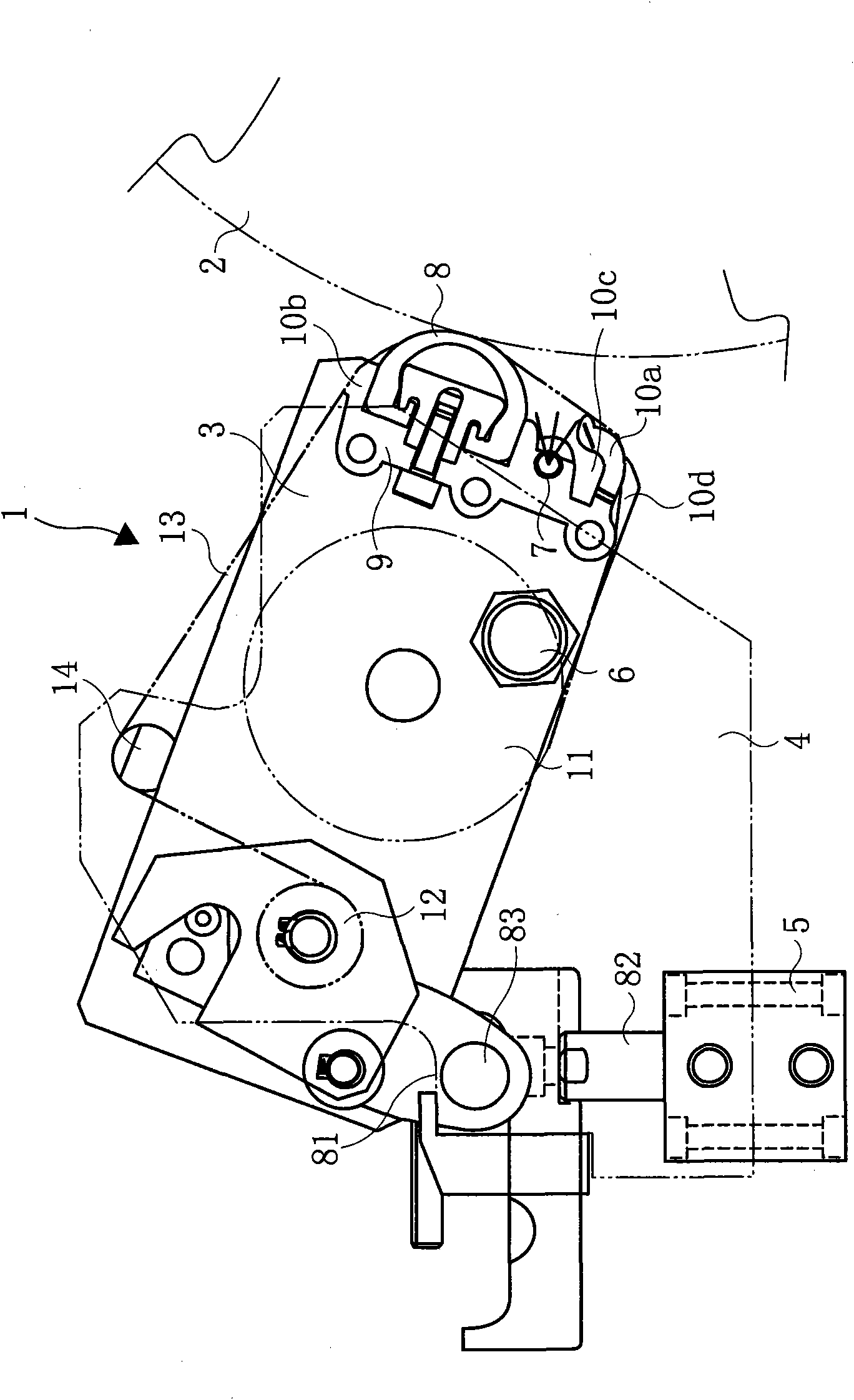

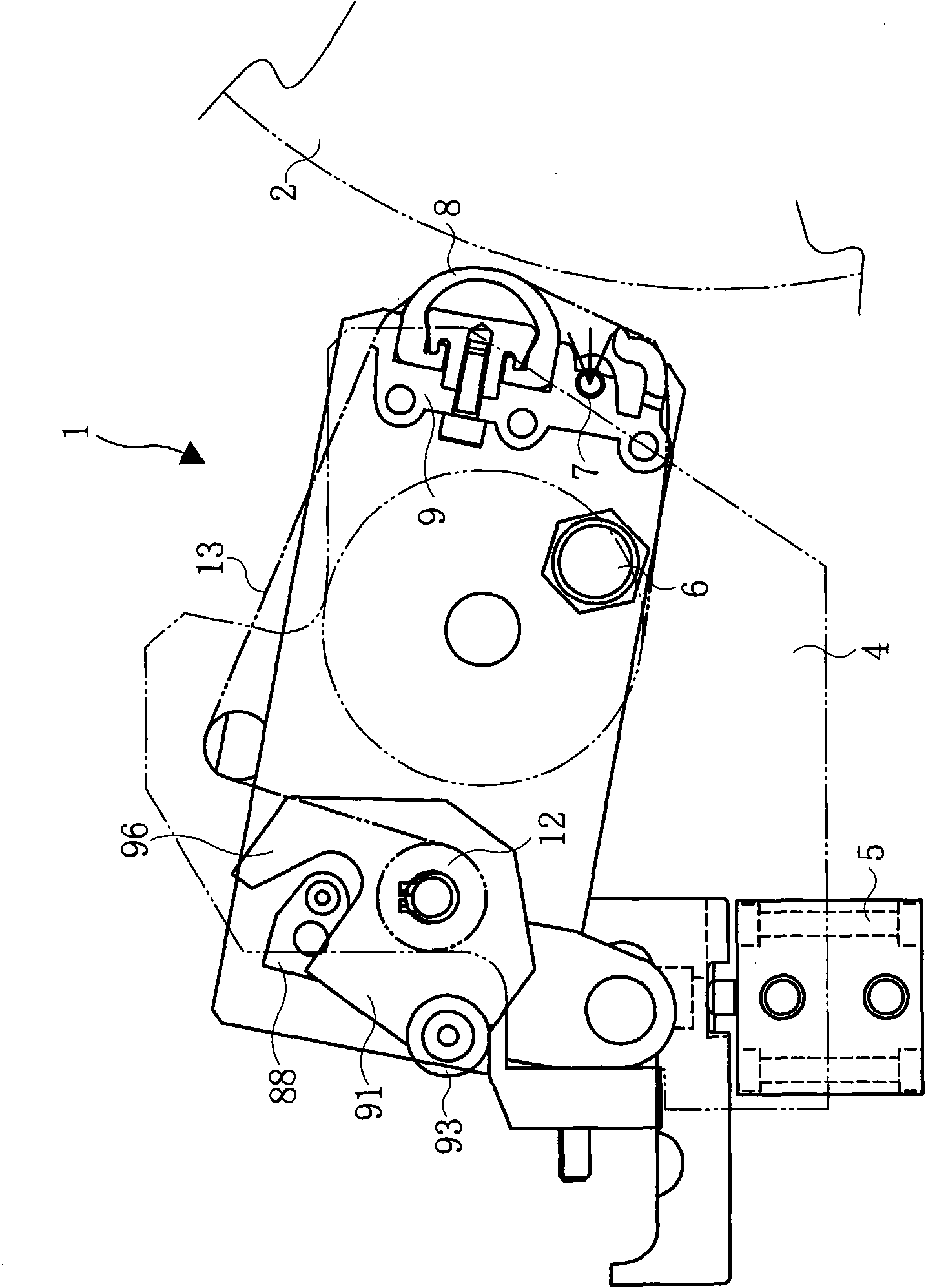

[0105] Embodiments of the present invention will be described below with reference to the drawings.

[0106] Figure 1-Figure 3 The cylinder cleaning device 1 of the first embodiment shown is disposed opposite to the blanket cylinder 2 to be cleaned, and the cylinder cleaning device 1 is composed of a pair of plates 3 on which a roller of a cleaning cloth is detachably mounted, and fixed outside the plates 3. The frame 4 provided on the frame of the printing machine constitutes a frame, and an air cylinder 5 as a source of a pressing means is provided on one frame 4 .

[0107] Through this air cylinder 5 , the cylinder cleaning device 1 rotates around the rotary shaft 6 , and plays a role of making it contact with and separate from the blanket cylinder 2 .

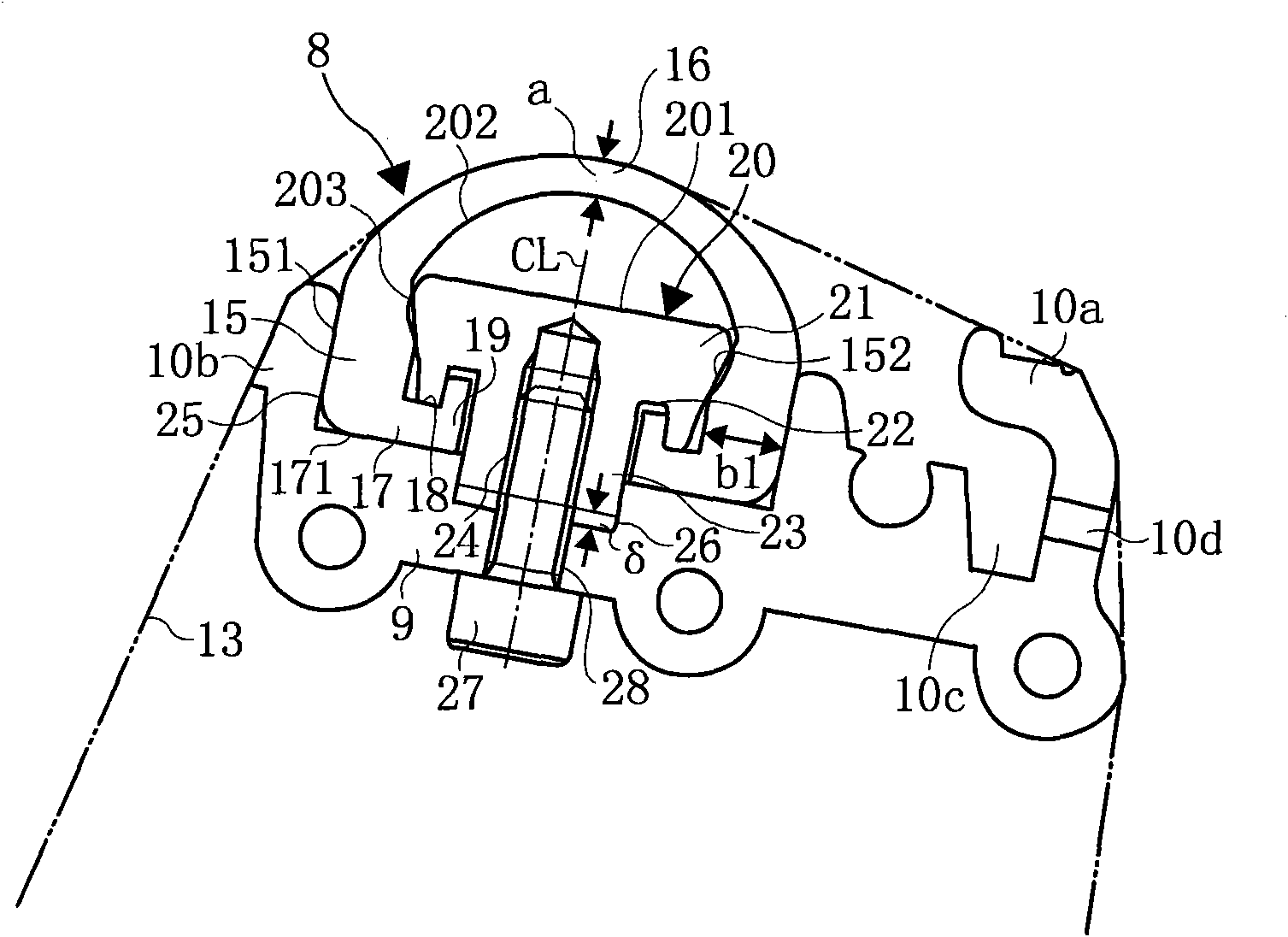

[0108] The pushing part is arranged on the opposite side of the rubber printing cylinder 2, such as image 3 As shown, it consists of a pad mounting plate 9 for mounting a pressing pad 8 as a pressing member, and guide p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com