Actuation means for a clutch

A control device and clutch technology, applied in clutches, mechanical equipment, etc., can solve problems such as lack of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

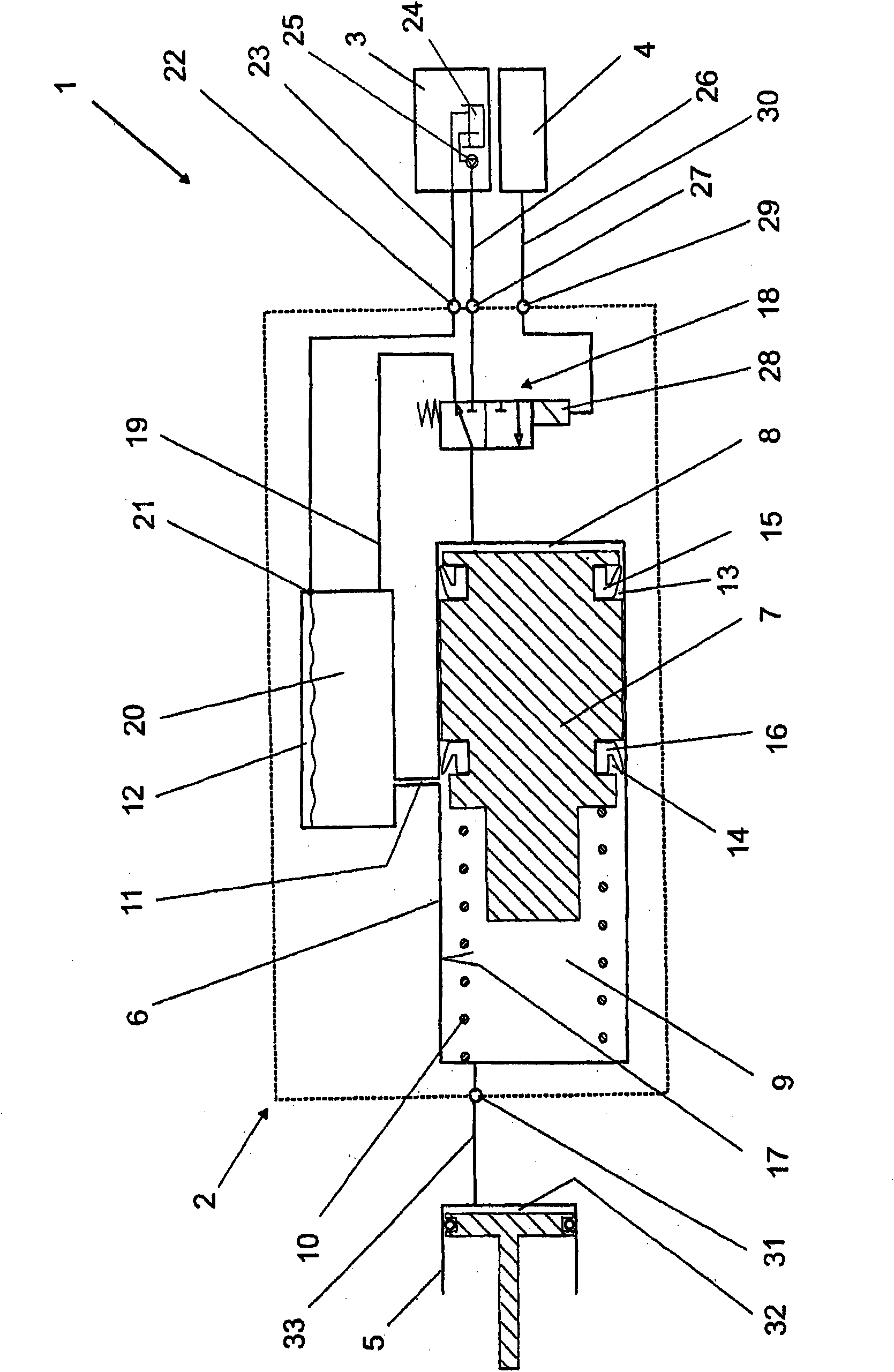

[0024] In order to operate the clutch, the clutch control device 1 mainly includes a control unit 2 , a hydraulic control device 3 , a controller 4 and a slave cylinder 5 .

[0025] The control unit 2 includes a master cylinder 6 whose inner cavity is divided into a slave oil chamber 8 and a master oil chamber 9 by a longitudinally displaceable master piston. Arranged in the master oil chamber 9 is a compression spring 10 which, in the depressurized state, presses the master piston 7 into its initial position in the slave oil chamber 8 . In the initial position of the active piston 7 , the active oil chamber is connected to the compensation container 12 via the compensation line 11 . The active piston 7 has ring grooves (Ringnut) 13, 14 towards the driven oil chamber 8 and towards the active oil chamber 9, respectively, in which a seal 15, 16 is respectively arranged for sealing with respect to the adjacent pistons. The cylinder inner wall 17 creates a seal. In addition to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com