Probe device for a metrology instrument and method of fabricating the same

A probe and probe head technology, which can be used in measurement devices, instruments, scientific instruments, etc., can solve problems such as unsatisfactory probe head formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

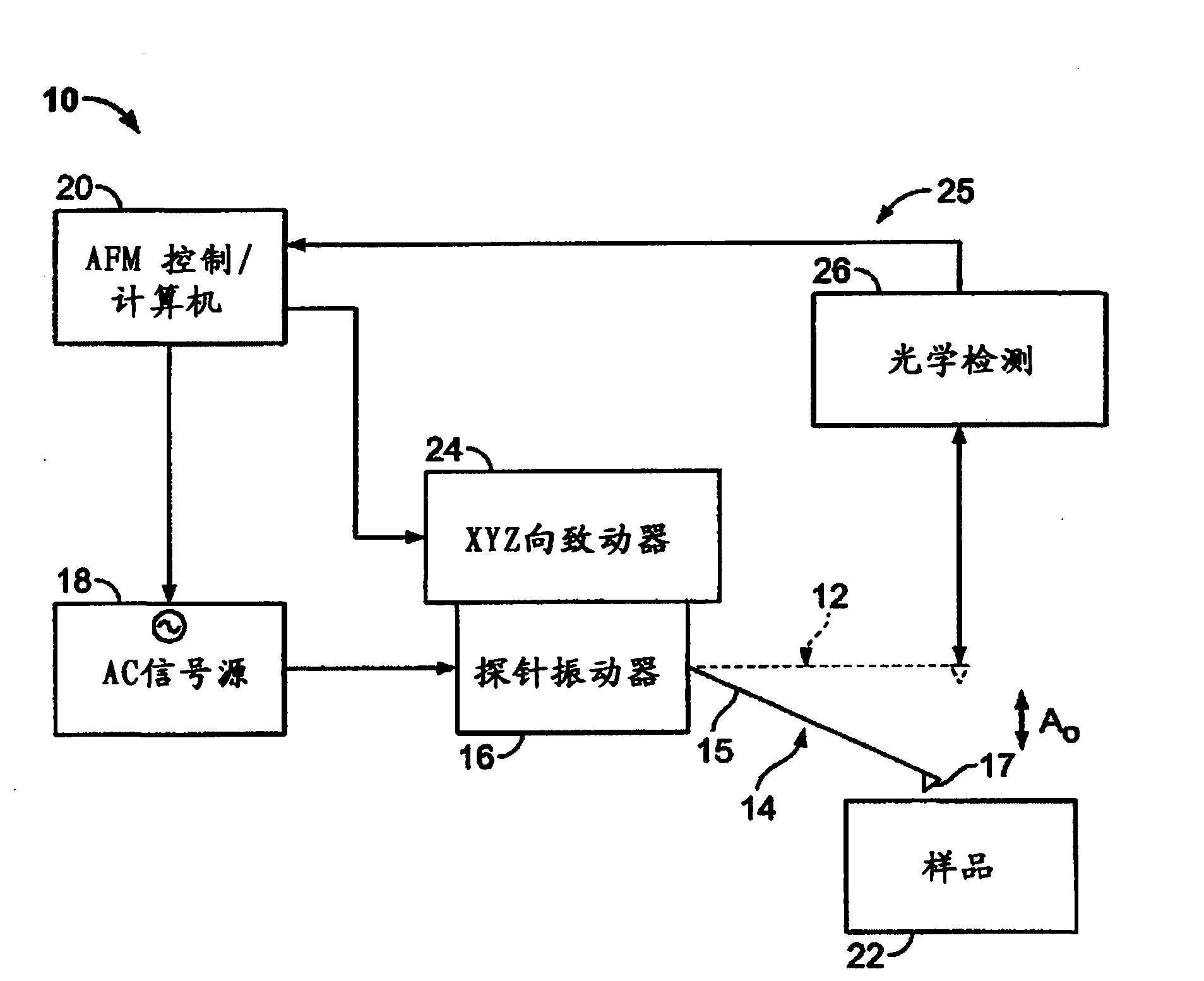

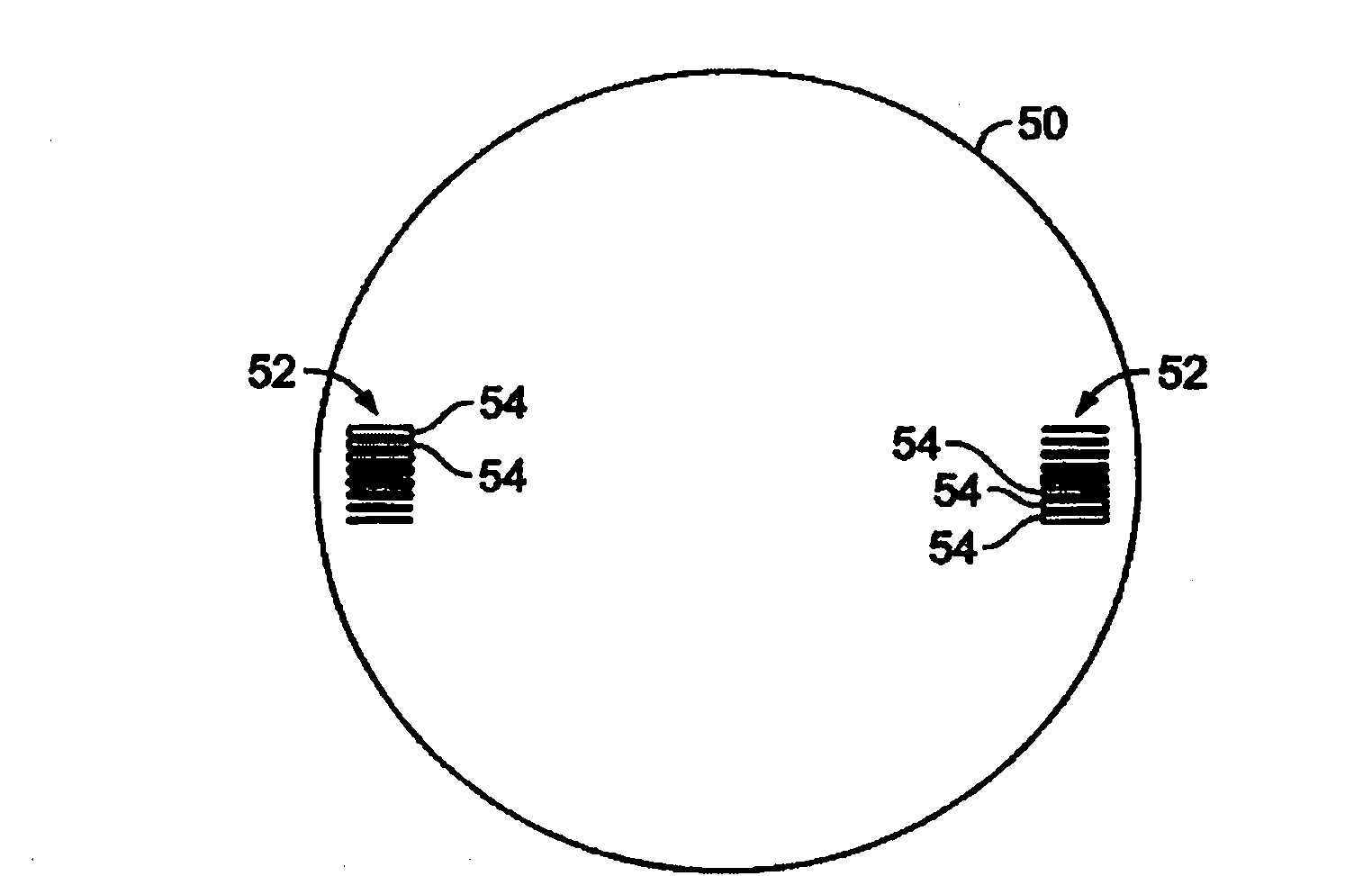

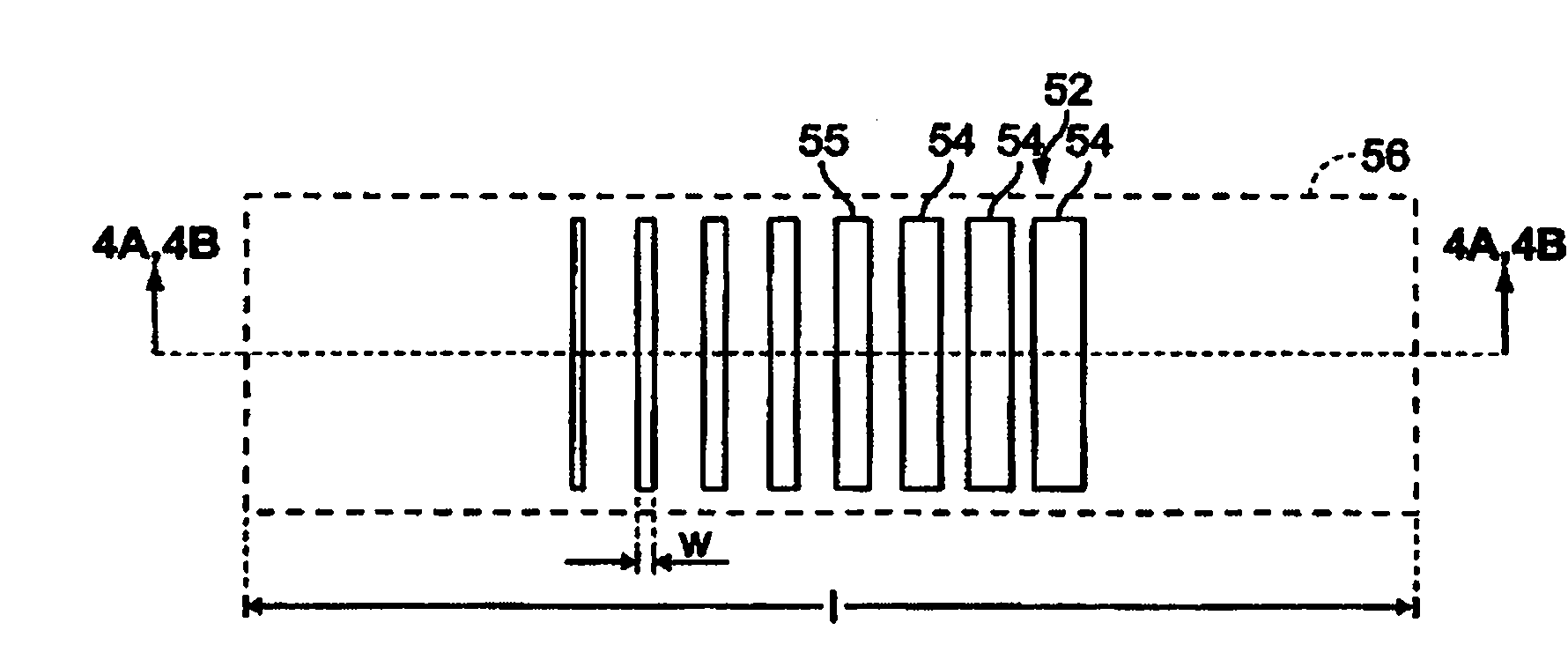

[0066]A preferred embodiment is directed to microfabrication techniques, wherein the probe arrangement is lithographically patterned and etched from a substrate such as a silicon wafer, ideally a bulk monocrystalline silicon wafer. As long as this method produces a probe with a high aspect ratio probe tip and a short cantilever and thus a large resonant frequency, the resulting probe device is particularly useful for high speed metrology applications, especially those using AFMs. According to the present invention, the yield of usable probe devices can be greatly increased with respect to known methods by maintaining the same substrate from which the probe devices can be produced (for example, the substrate can be lightly doped or undoped bulk Silicon) type-dependent flexibility, and provide a solution to align the probe head of the probe device with the fixed end of the cantilever from the front side of the wafer without moving the wafer, thereby enabling precise control of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com