Steel mill of grain mill

A technology of milling machine and steel mill, which is applied in grain processing and other directions, and can solve problems such as difficult control and tediousness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

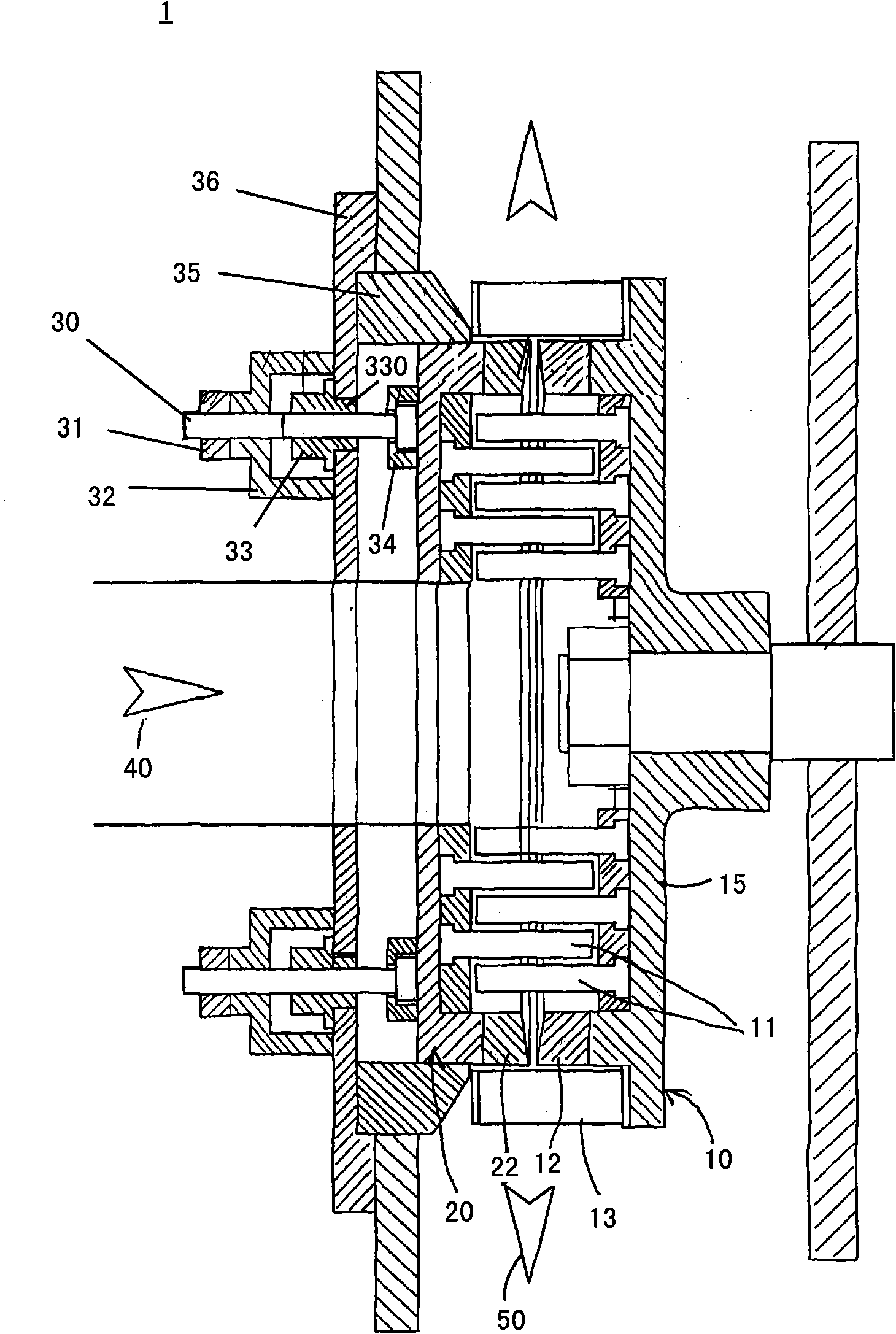

[0020] Such as Figure 1 to Figure 3 As shown, the steel mill 1 includes a movable cutter head 10 and a static cutter head 20 .

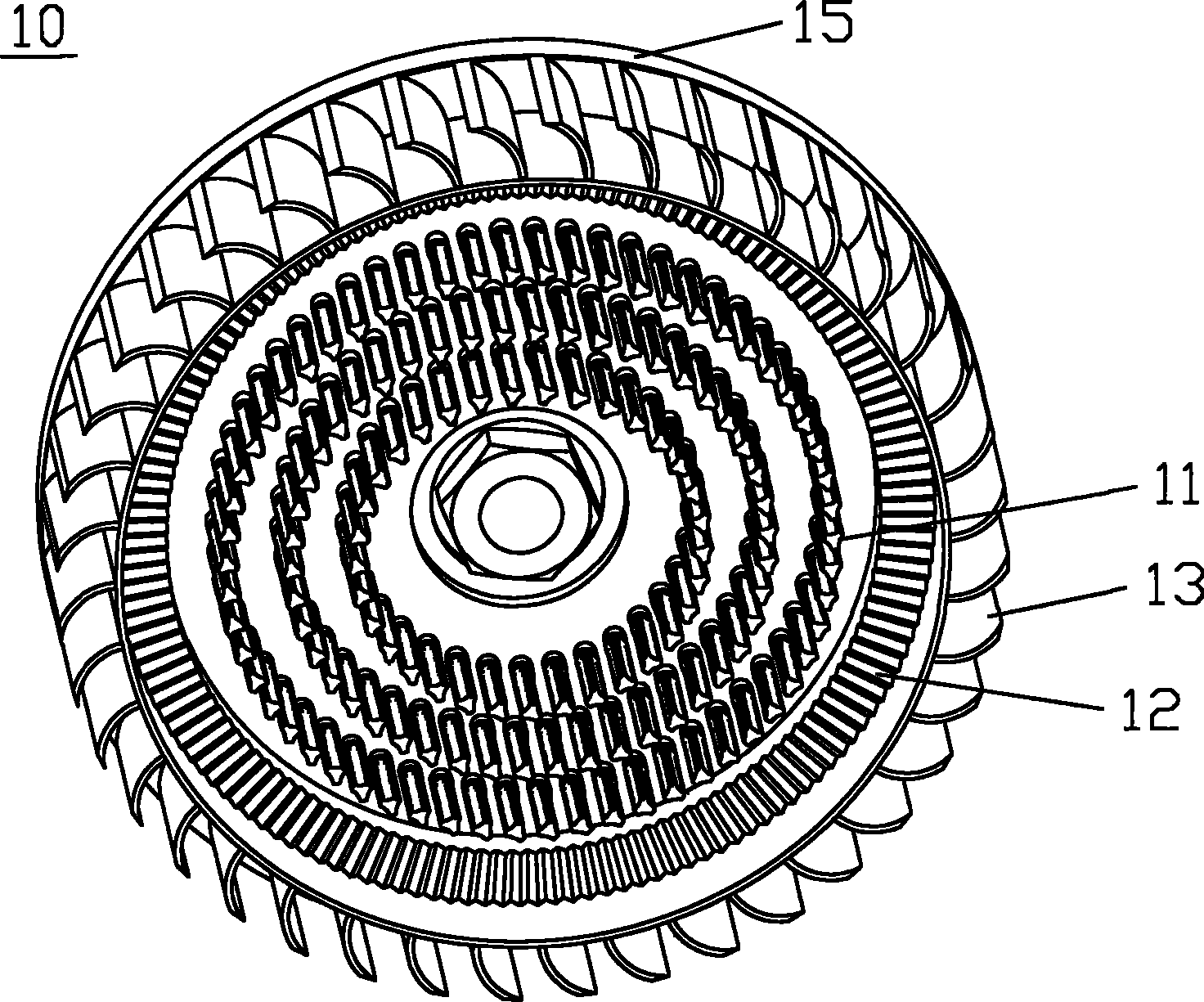

[0021] The movable cutter head 10 has a circular grinding knife 12 , multiple groups of pulverizing knives 11 and blades 13 arranged in a ring. The blades 13 are centrifugal blades. The grinding knife 12 , the pulverizing knife 11 and the blade 13 are all fixedly arranged on the flywheel tool holder 15 .

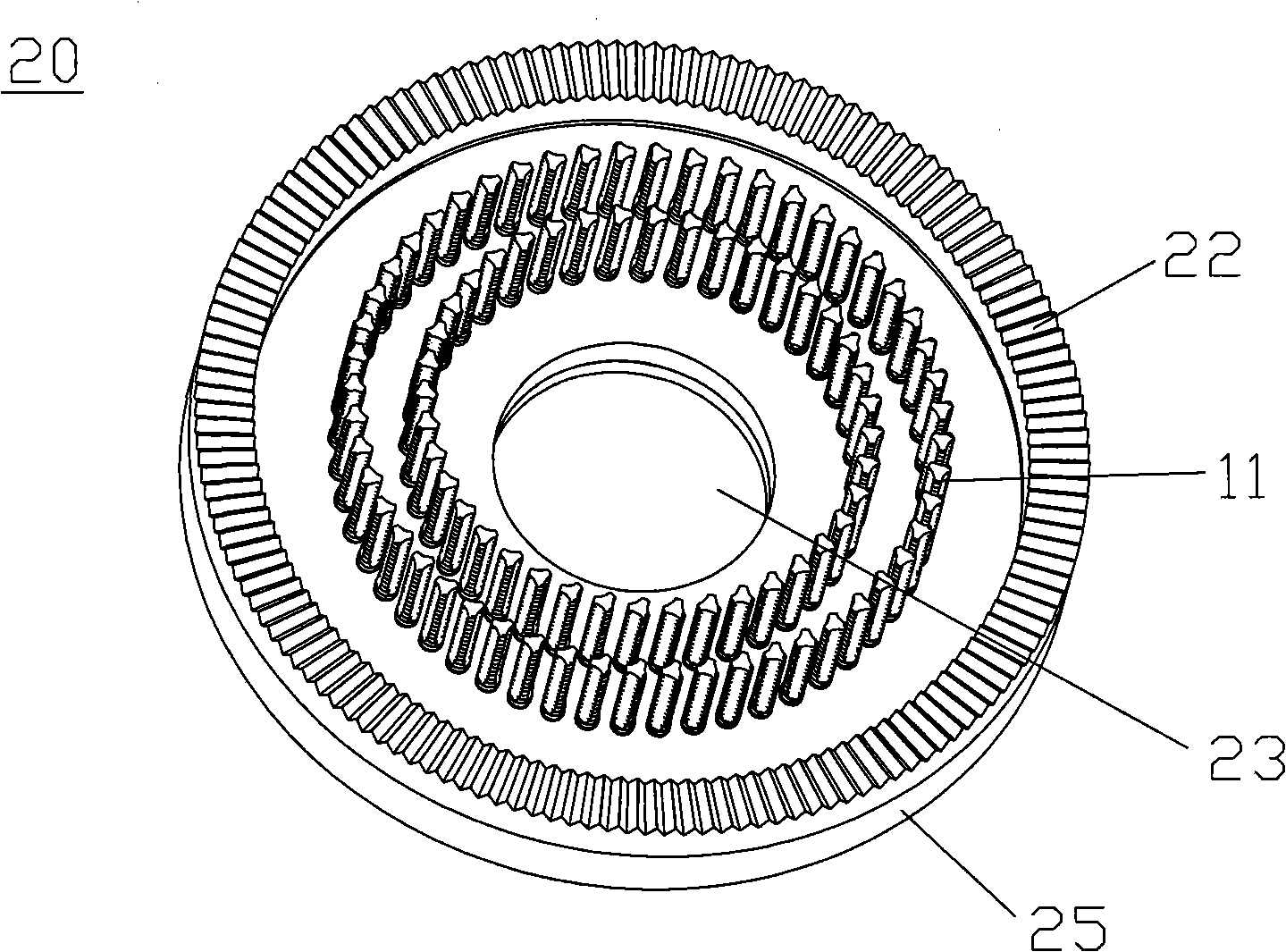

[0022] The static cutter head 20 has arc-shaped grinding blades 22 , multiple groups of pulverizing blades 11 and an opening 23 on the end surface. The grinding knife 22 and the crushing knife 11 are all arranged on the knife holder seat 25 . The end face opening 23 runs through the inner and outer end faces of the knife rest seat 25 and is arranged at the center of the knife rest seat 25 .

[0023] When working, the processing material enters the cavity formed by the movable cutter head 10 and the static cutter head 20 of the steel mill 1 acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com