Mined out space dam-type filling method

A technology for gobs and embankments, which is applied to filling materials, mining equipment, earthwork drilling and mining, etc. It can solve the problems of limited effect of controlling ground surface subsidence, low filling efficiency, and high filling cost, and achieves wide practicability and high filling efficiency. High, reduce the effect of empty head distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Implementation of the present invention will be further described below in conjunction with accompanying drawing:

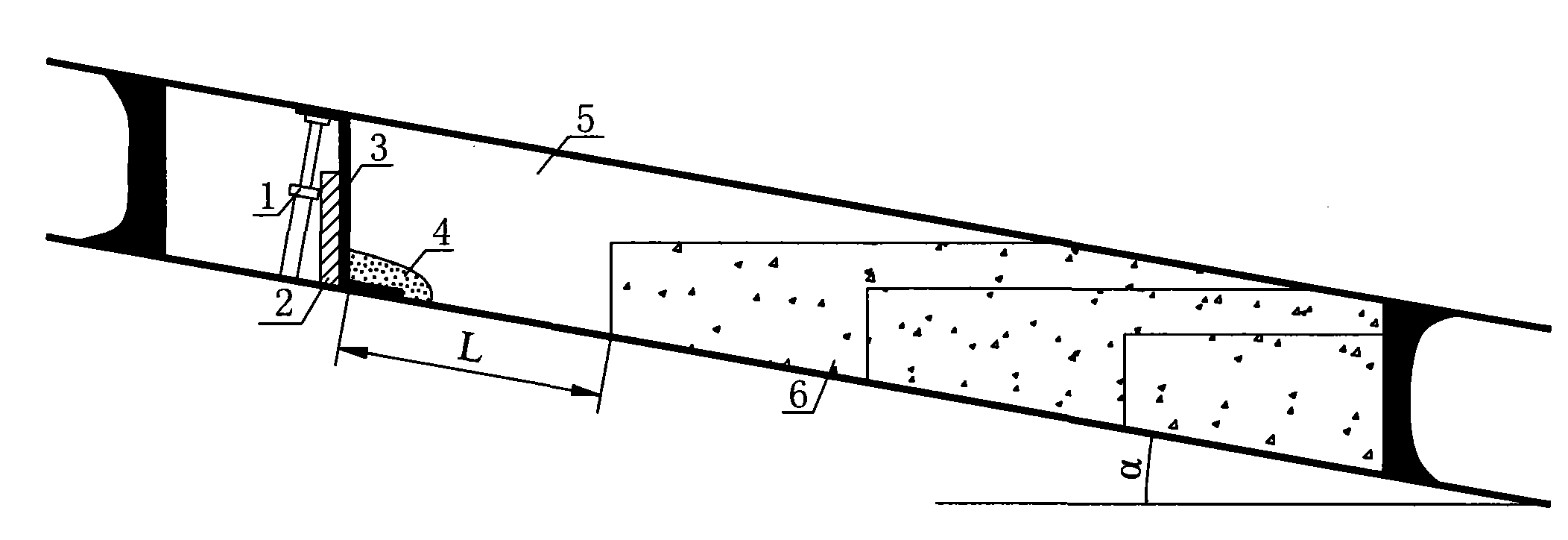

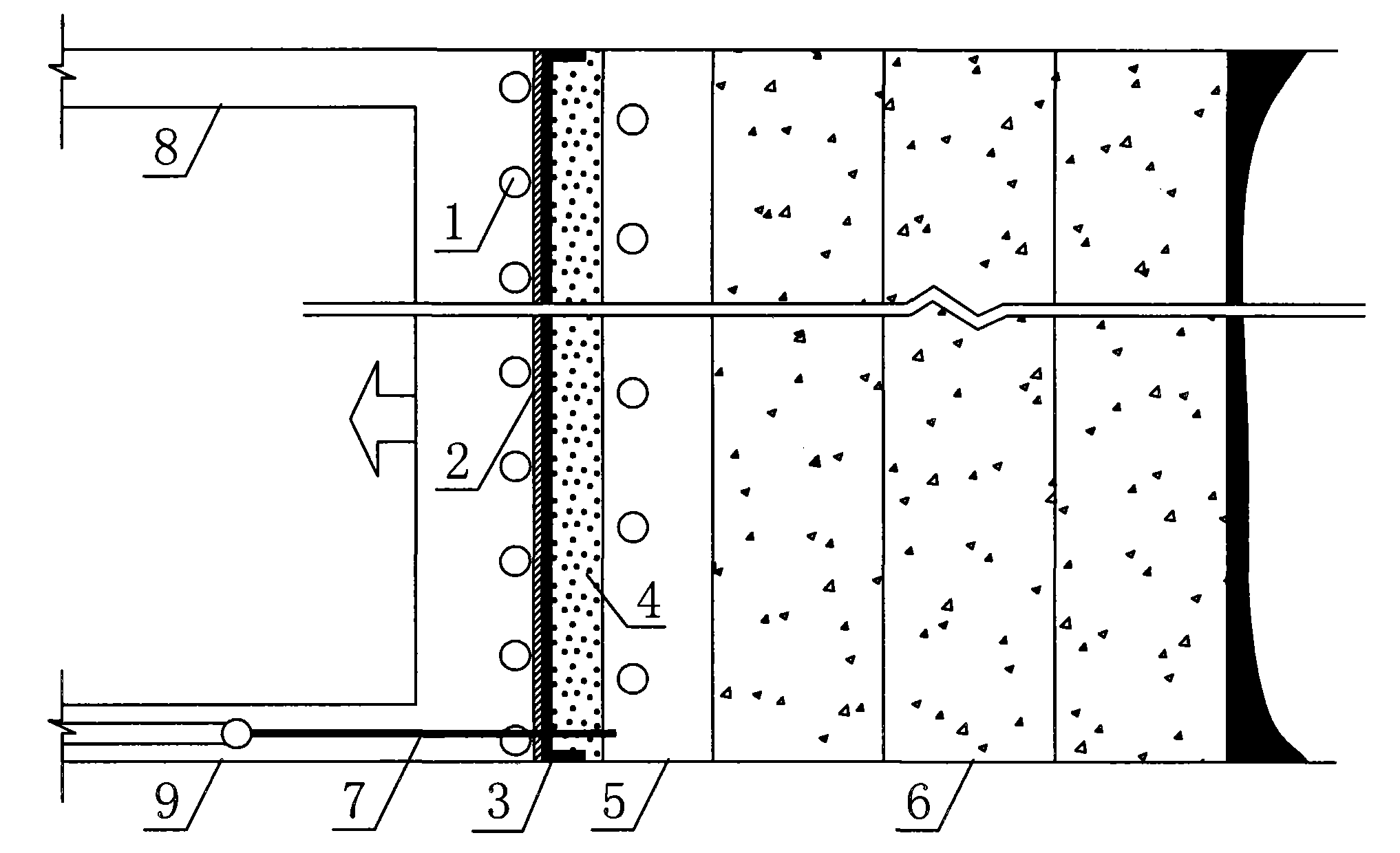

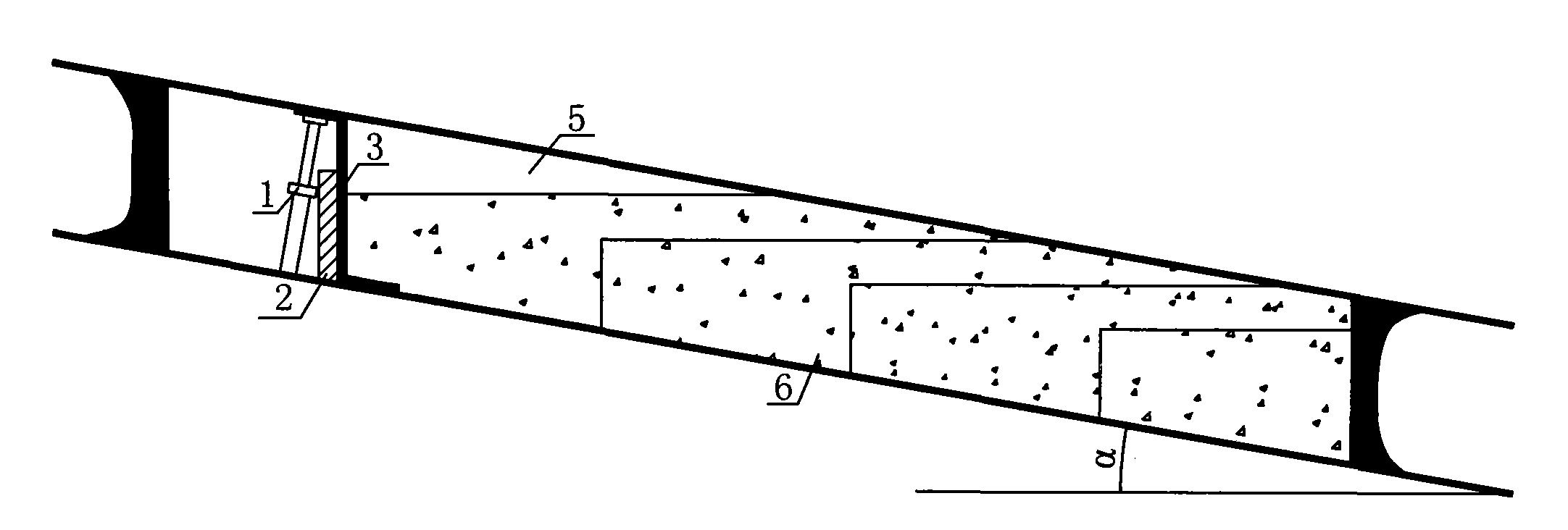

[0022] Goaf type filling method of the present invention: as figure 1 As shown, multiple single hydraulic props 1 are first erected on the upward mining face, and then the advancing distance L on the upward mining face is 3 to 5 m, which can ensure that the distance between the empty roof of the isolated goaf is always smaller than that of the direct roof or The first collapse step of the old roof; after that, the baffle plate 2 relying on the single hydraulic prop 1 is erected in the gob area behind the single hydraulic prop 1 of the top-cut row, and the height of the erected baffle 2 is 100% 60% to 80%. Attached to the baffle plate 2, the flexible water-proof cloth 3 extending to the bottom plate and the two lanes of the working face is laid from top to bottom to form an isolated goaf 5. The material of the laid flexible water-proof cloth 3 is waterproo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com