Compound oil cylinder and refuse compactor thereof

A composite oil cylinder and cylinder body technology, which is applied in the direction of presses, stamping machines, garbage transmission, etc., can solve the problems of inaccurate control of the position of the oil cylinder, damage to the front door of the garbage bin, loss of users and manufacturers, etc., to achieve simple and compact structure and improve safety performance and small installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

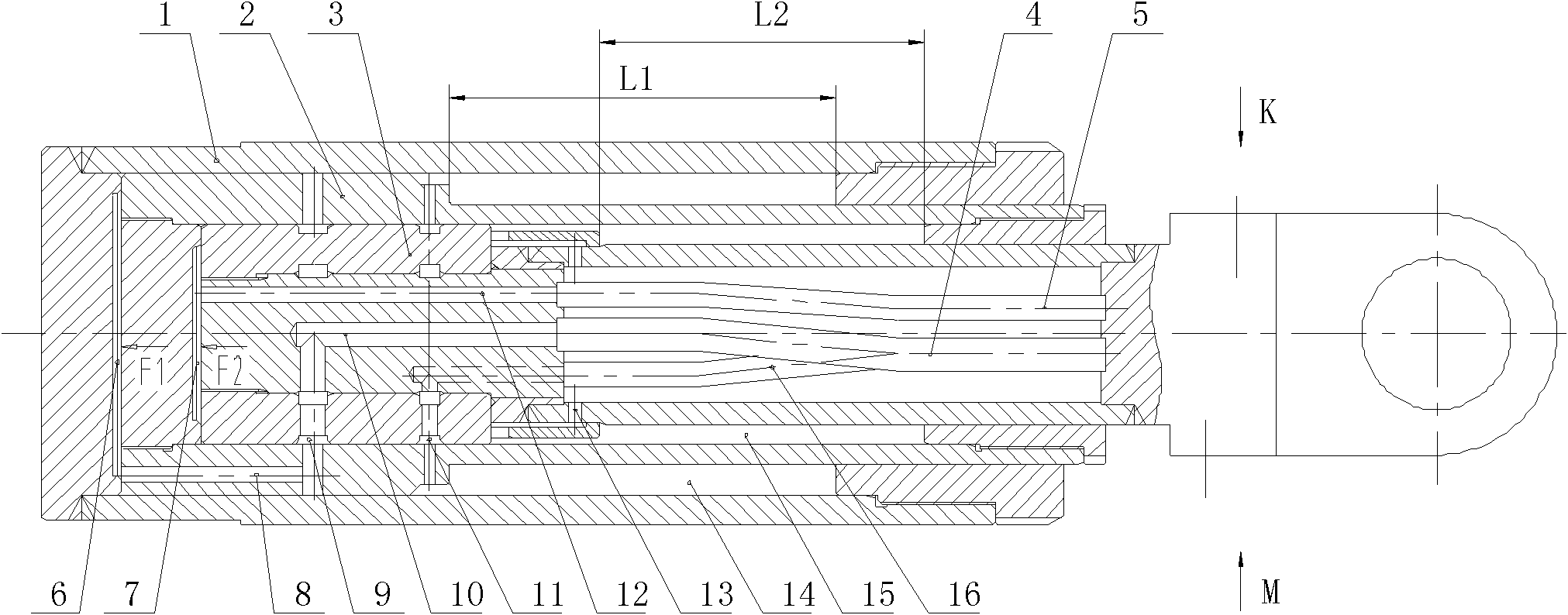

[0026] Such as figure 1 , figure 2 and image 3 As shown, the composite oil cylinder of the present invention includes a cylinder body 1, a first-stage piston rod assembly 2 and a second-stage piston rod assembly 3, and the first-stage piston rod assembly 2 is sleeved in the cylinder body 1 and the inside of the cylinder body 1 The cavity is divided into a first-stage cylinder rodless chamber 6 and a first-stage cylinder rod chamber 14. The second-stage piston rod assembly 3 is sleeved in the inner cavity of the first-stage piston rod assembly 2. The second-stage piston rod assembly 3 connects the first The cavity of the first-stage piston rod assembly 2 is divided into a second-stage cylinder rodless chamber 7 and a second-stage cylinder rod chamber 15 . During the extension process of the first-stage piston rod assembly 2, that is, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com