On-line monitoring plant for ferromagnetic grains in engine oil

A monitoring device and ferromagnetic technology are applied in the field of on-line monitoring device for ferromagnetic particles of oil and on-line monitoring device for wear state of mechanical equipment. Simple structure, reduction of accidents, and the effect of significant economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below, the present invention will be described in further detail in conjunction with the accompanying drawings and specific embodiments.

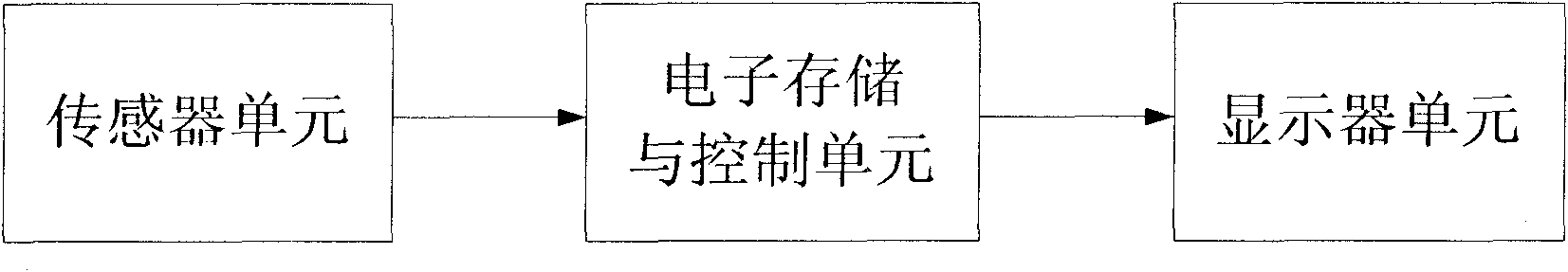

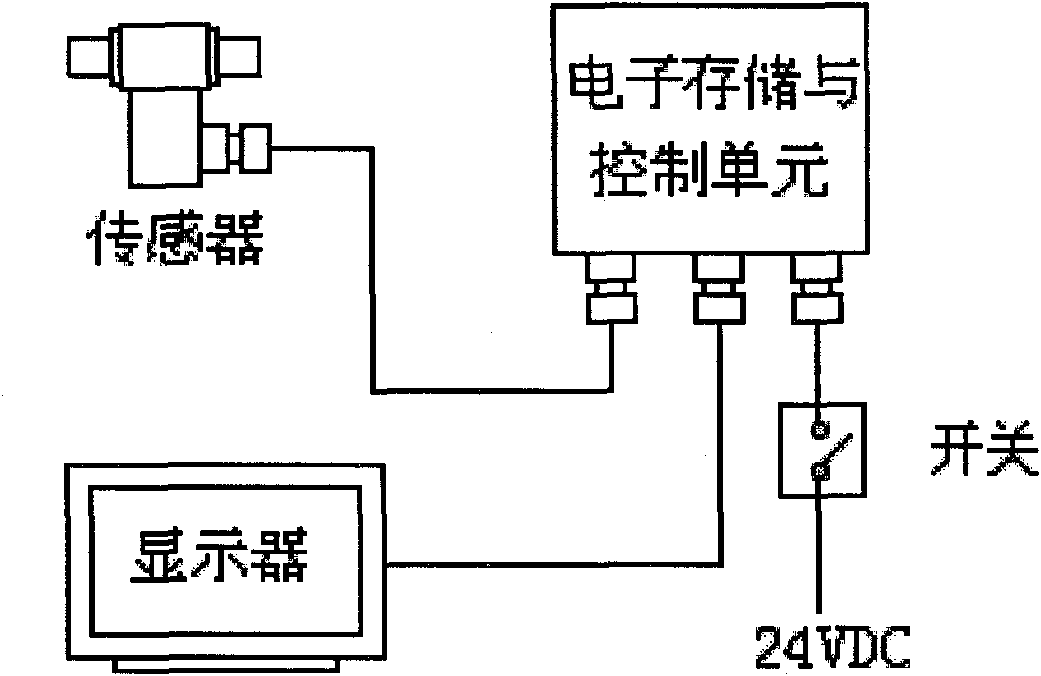

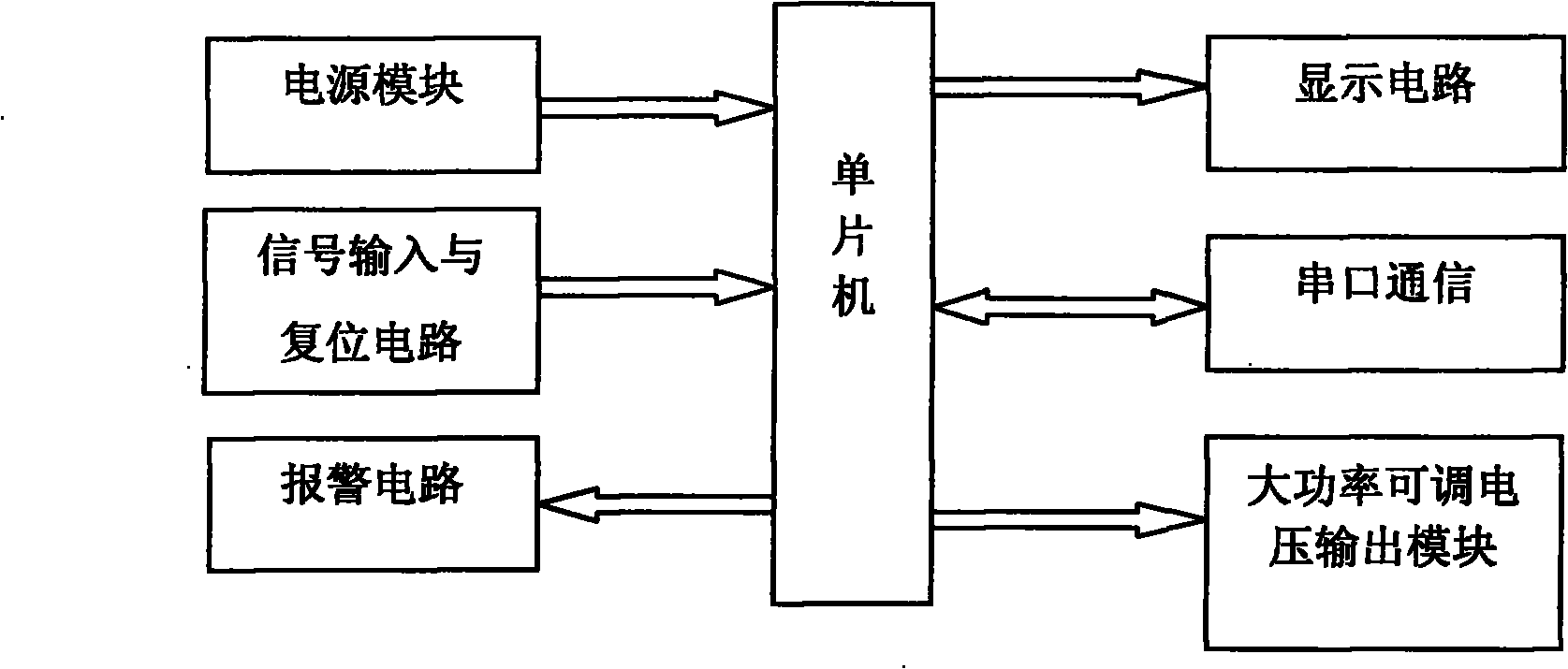

[0026] figure 1 It is a block diagram of an online monitoring device for ferromagnetic particles of oil in the oil circuit; figure 2 It is a schematic diagram of the on-line monitoring device for ferromagnetic particles in oil in the oil circuit; figure 1 , figure 2 As shown, the on-line monitoring device for ferromagnetic particles in engine oil includes a sensor unit installed in the oil circuit to be tested that matches the diameter of the oil circuit to be tested, an electronic storage and control unit and a display unit installed outside the oil circuit to be tested , the sensor unit is connected to the electronic storage and control unit through ordinary cables, and the electronic storage and control unit is connected to the display unit through the RS232 or RS422 / 485 series interface of common industrial standards. detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com