Patents

Literature

91results about How to "Significant economic value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

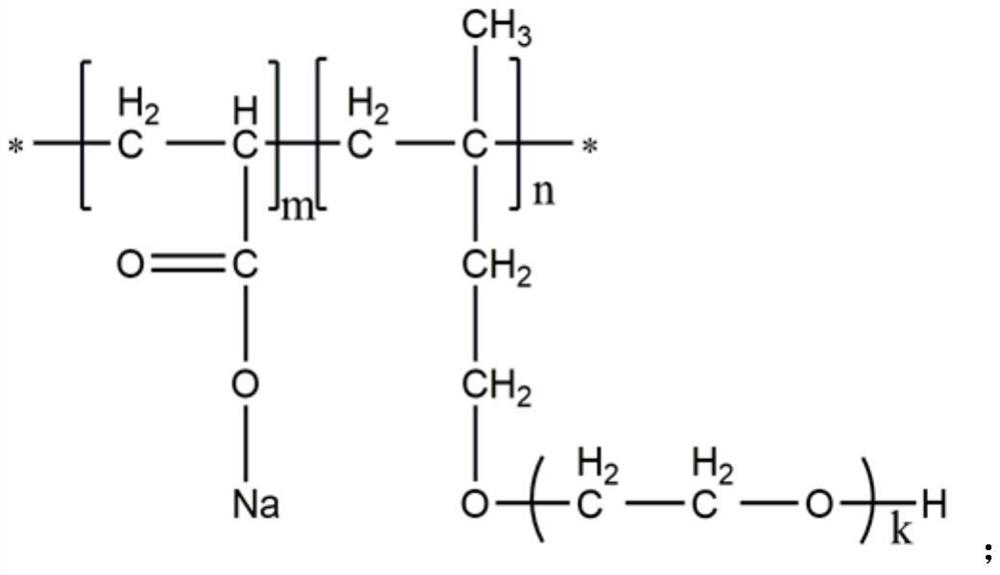

Apparatus and Process for the Pyrolysis of Agricultural Biomass

InactiveUS20080197012A1Prevent escapeFast heat transferFluidized bed combustionCombustible gas coke oven heatingCombustion chamberFluidized bed

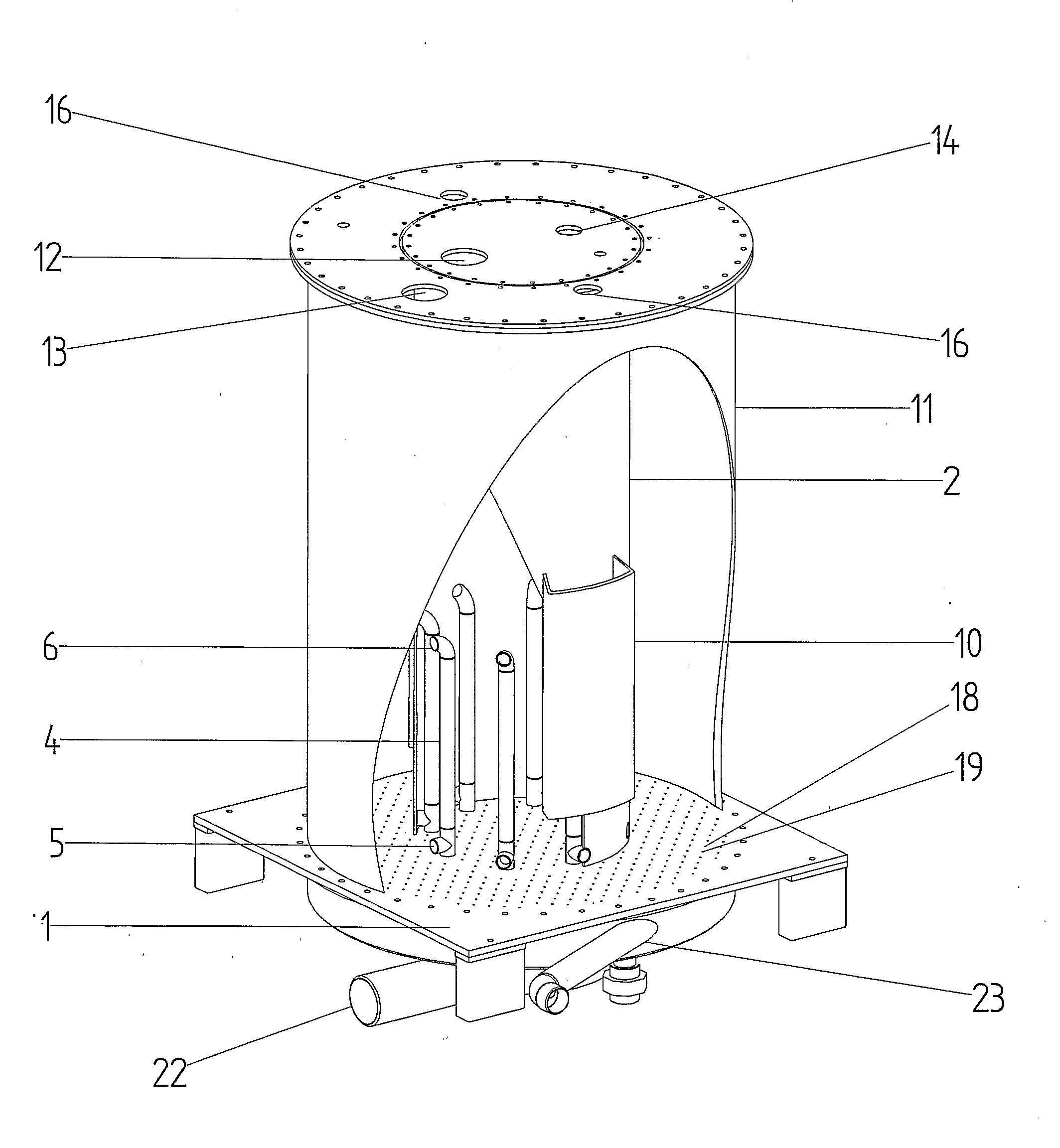

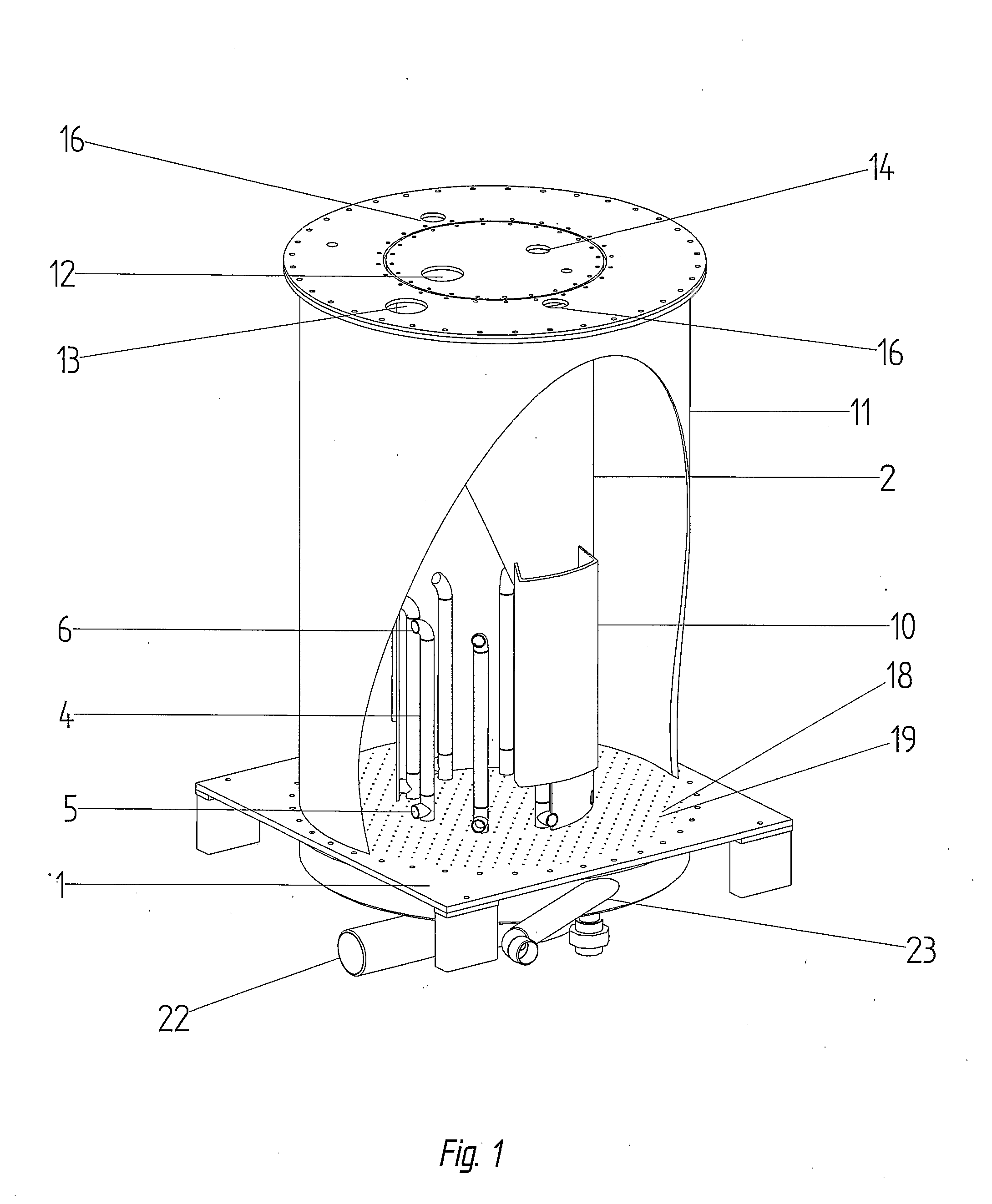

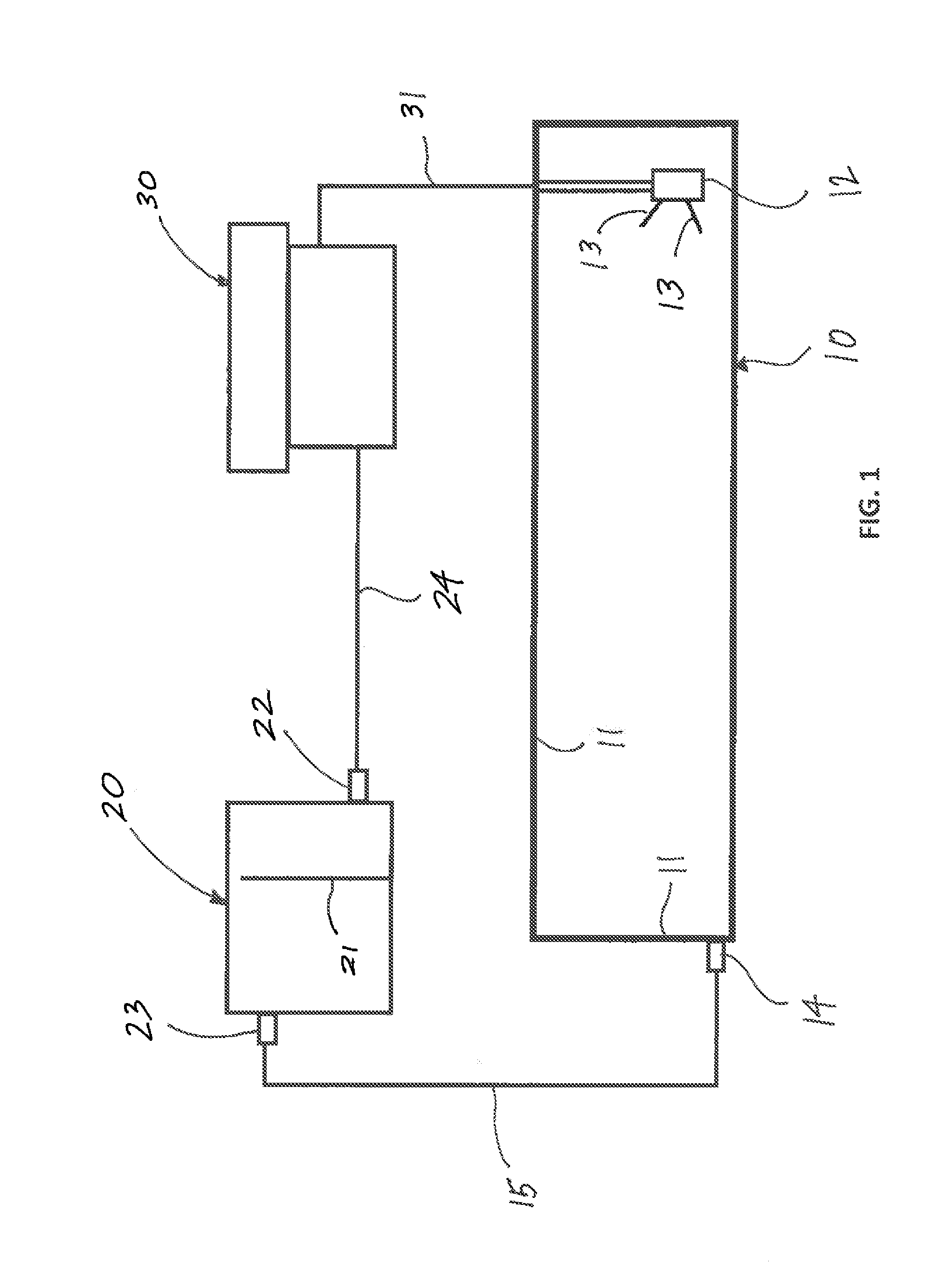

An integrated combustion chamber and fluidized bed pyrolysis reactor. In one embodiment, the combustion chamber is cylindrical and the pyrolysis reactor is provided annularly about the combustion chamber with an annular wall that provides a common surface for heat transfer. A lift tube in fluid communication with the pyrolysis reactor is provided within the combustion chamber for circulating biomass and an inert fluidizable media upwardly through the lift tube; this advantageously increases heat transfer and leads to more rapid pyrolysis. The media and biomass exit the lift tube into either a freeboard area of the pyrolysis reactor or into a low density region of the fluidized bed. A condensable gaseous product is produced during pyrolysis that has economic value. The apparatus and process are especially well suited to the pyrolysis of low density agricultural biomass. The apparatus is compact and particularly well suited to mobile operation.

Owner:AGRI THERM

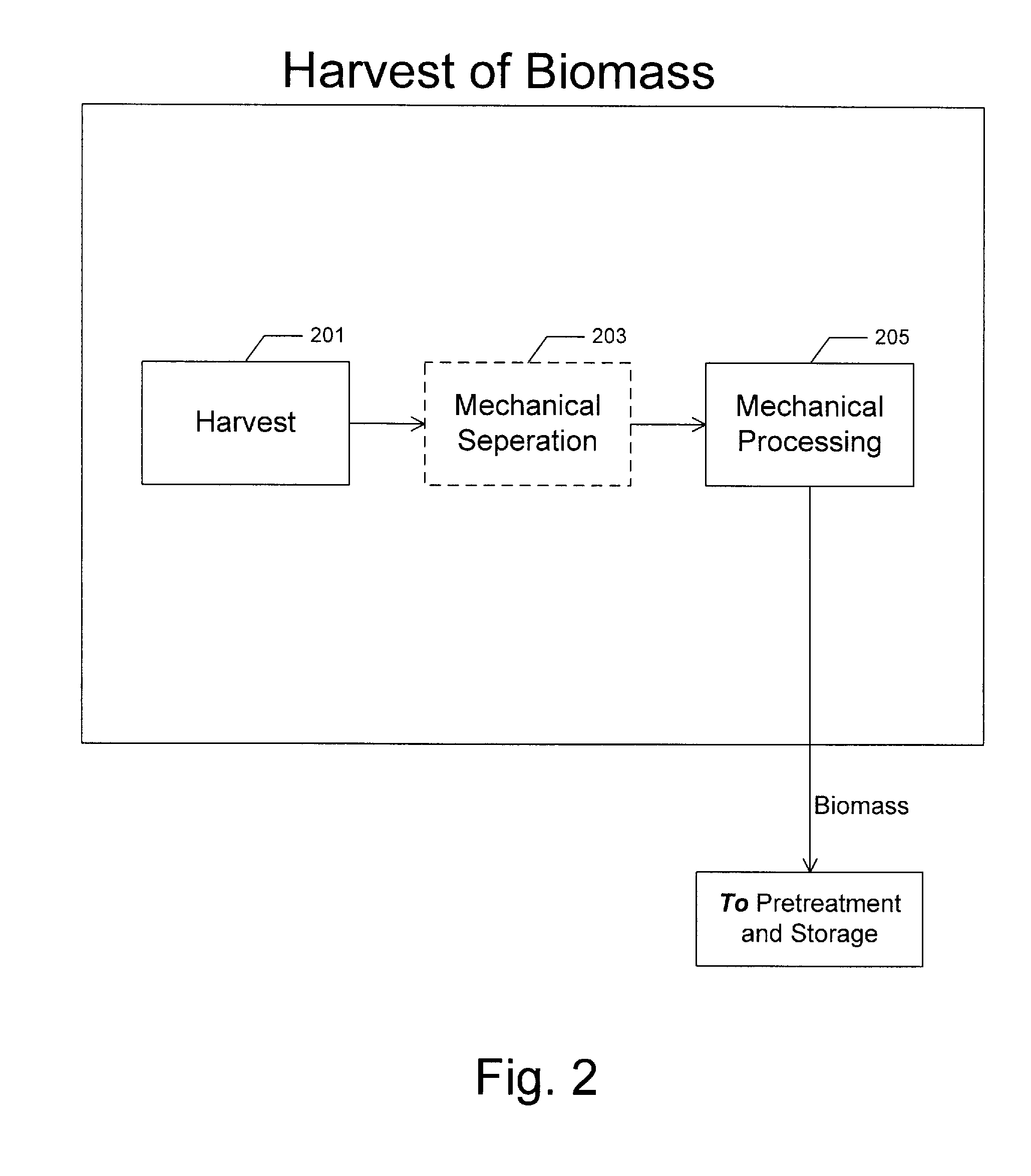

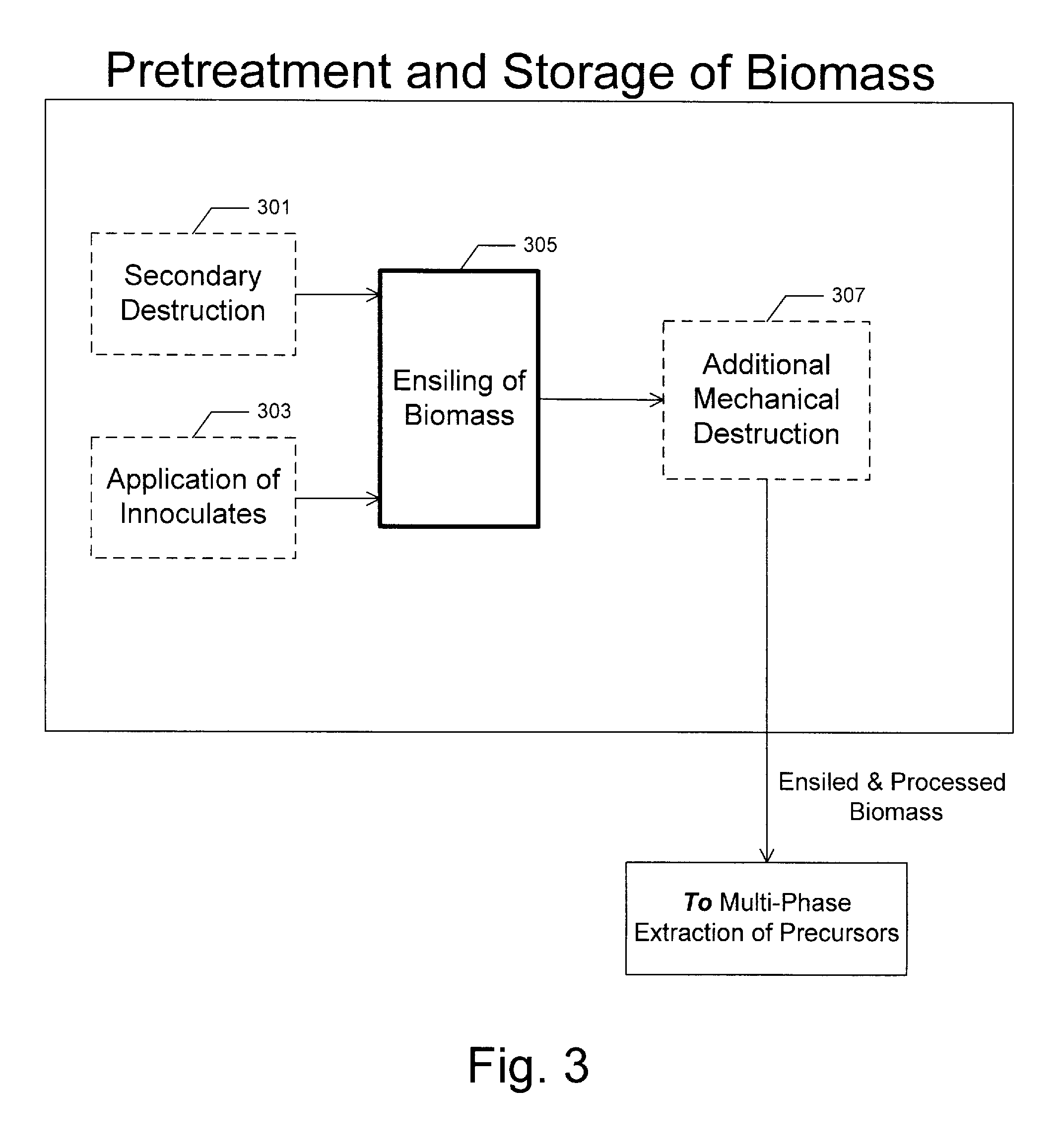

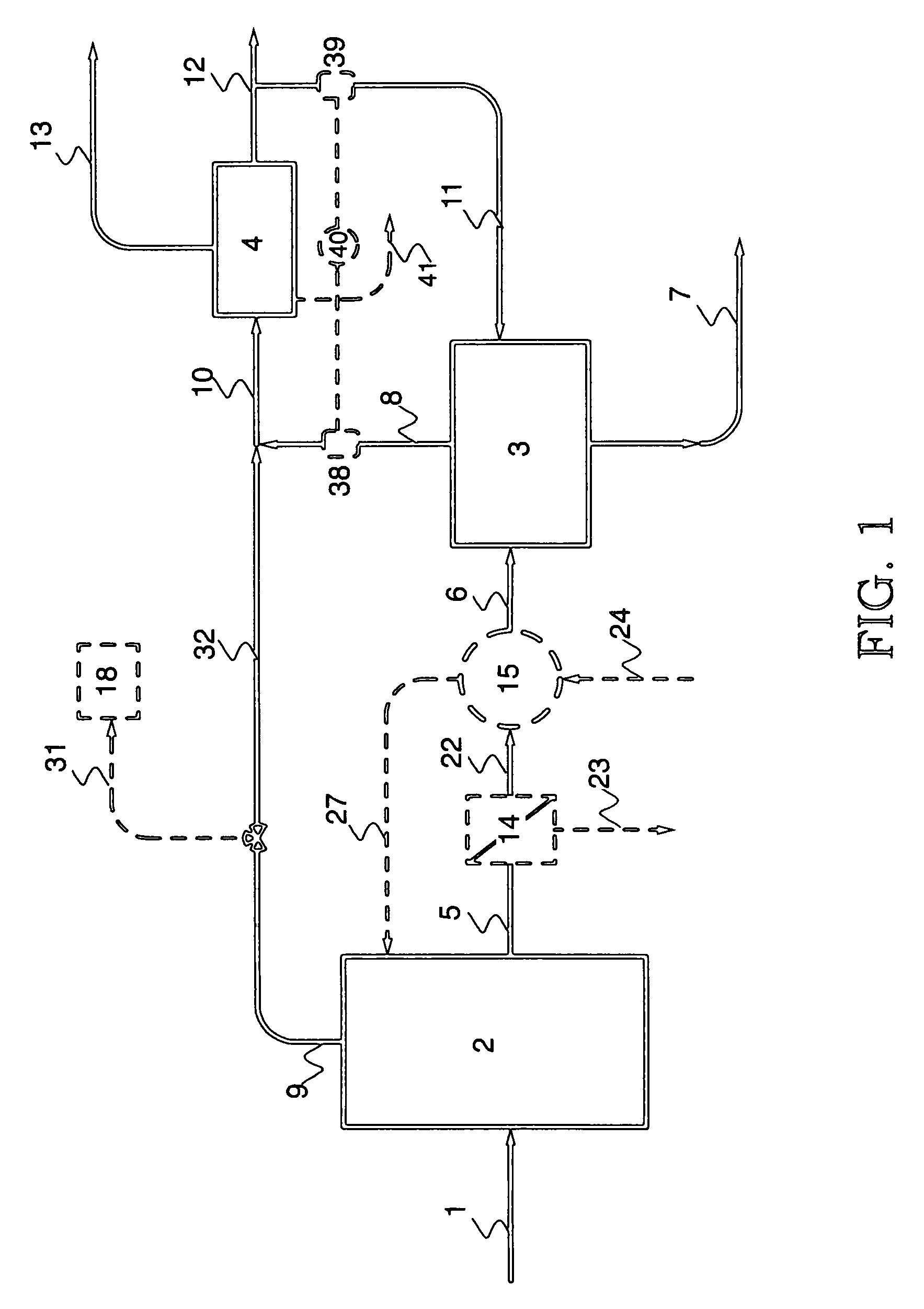

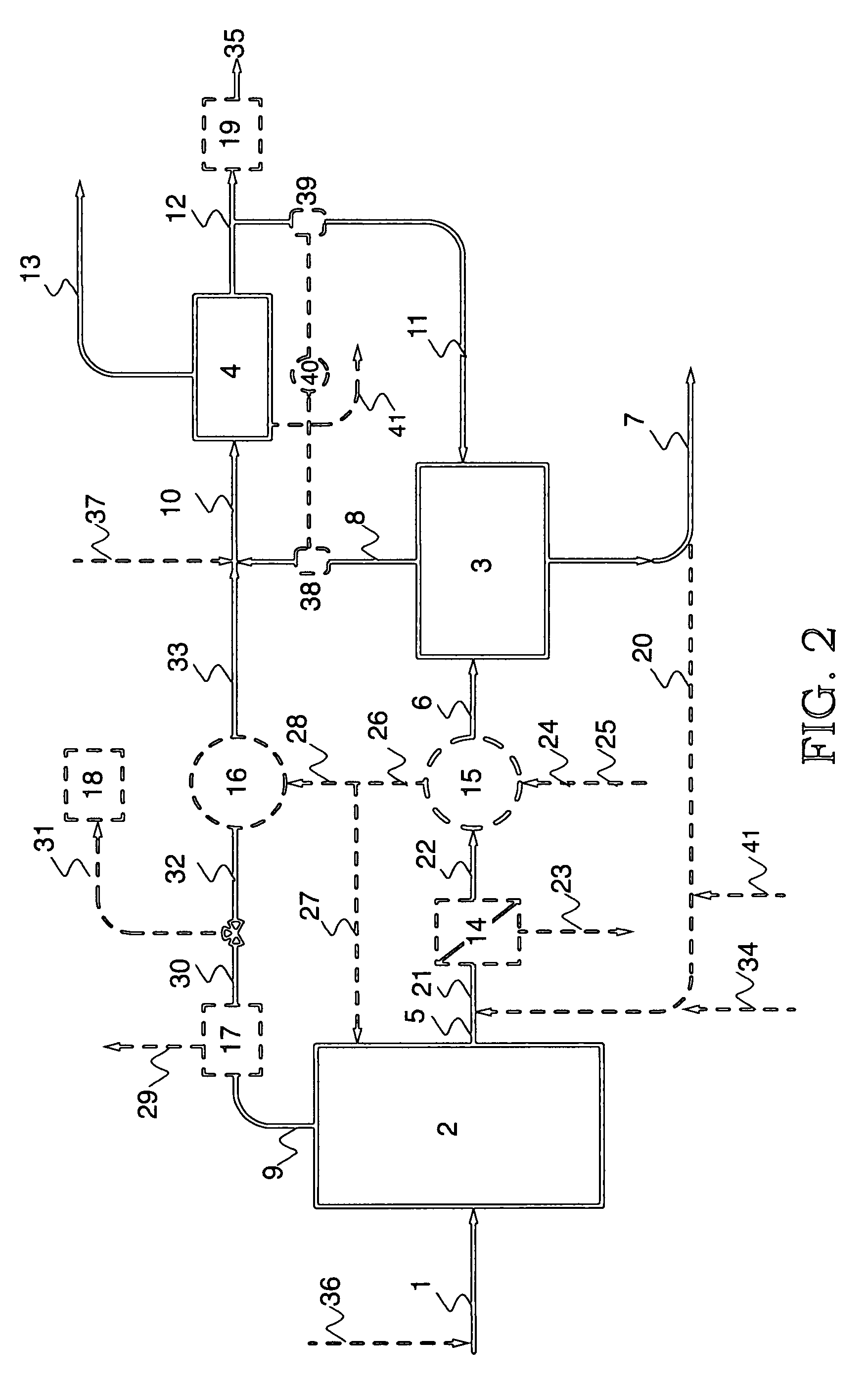

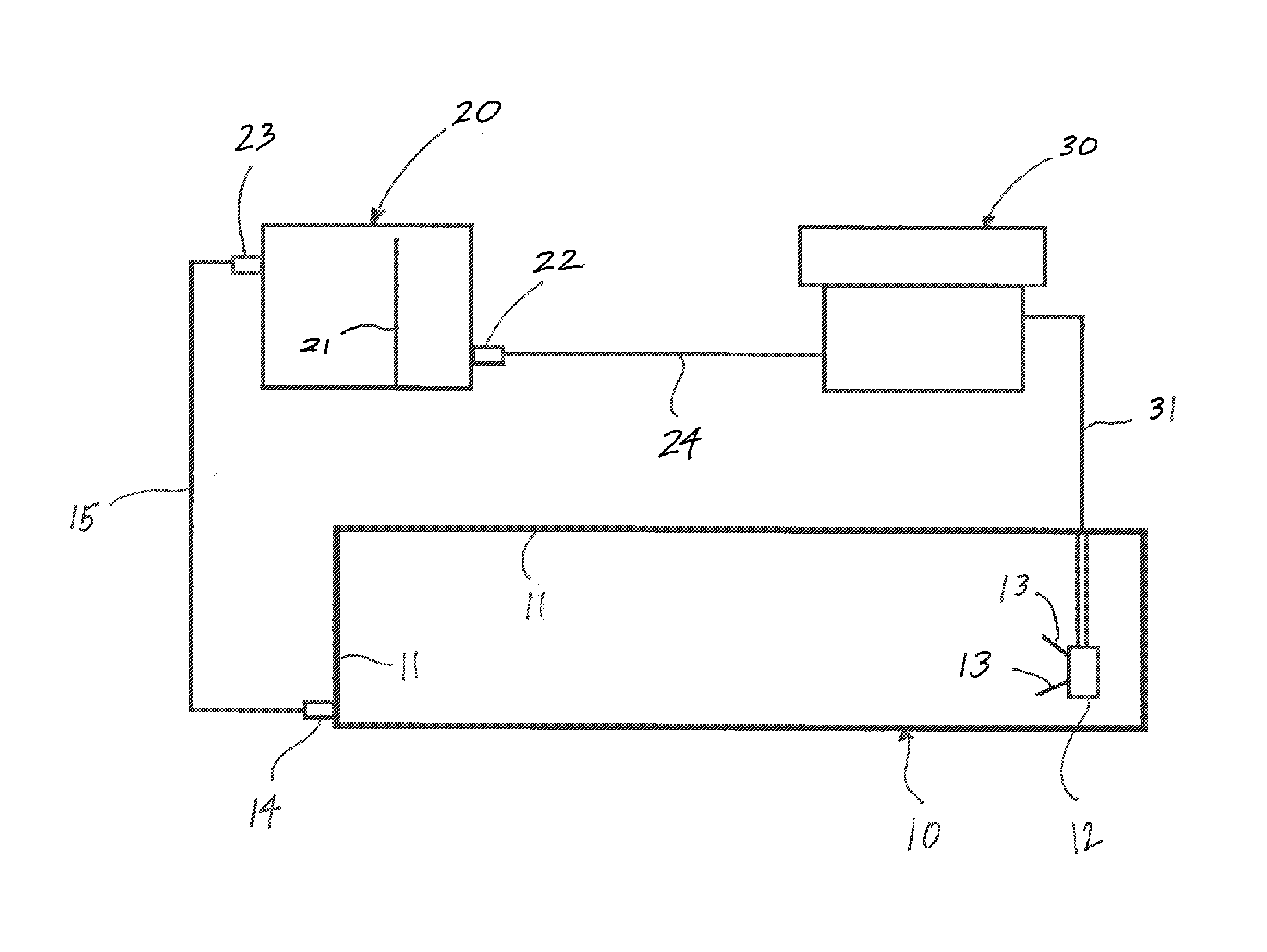

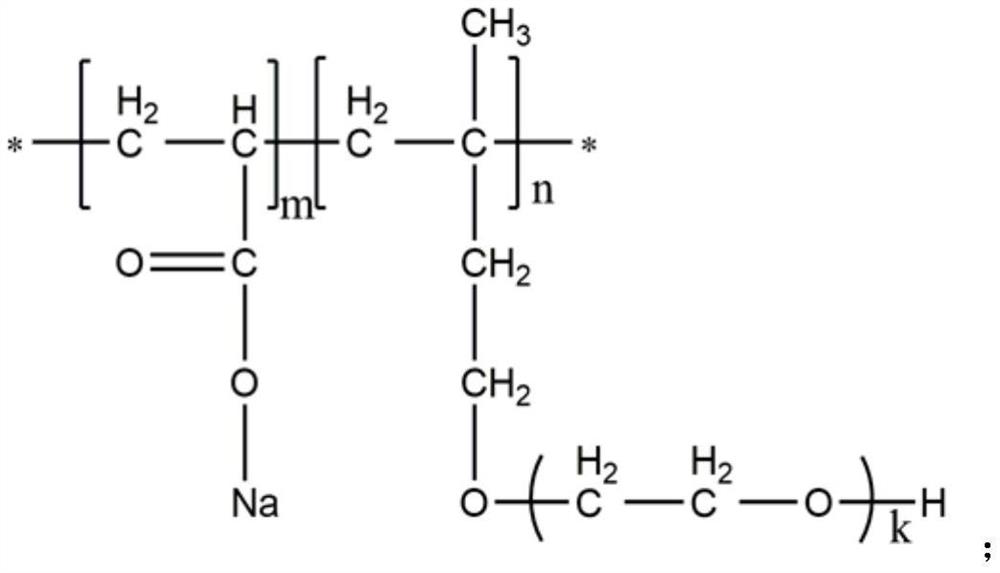

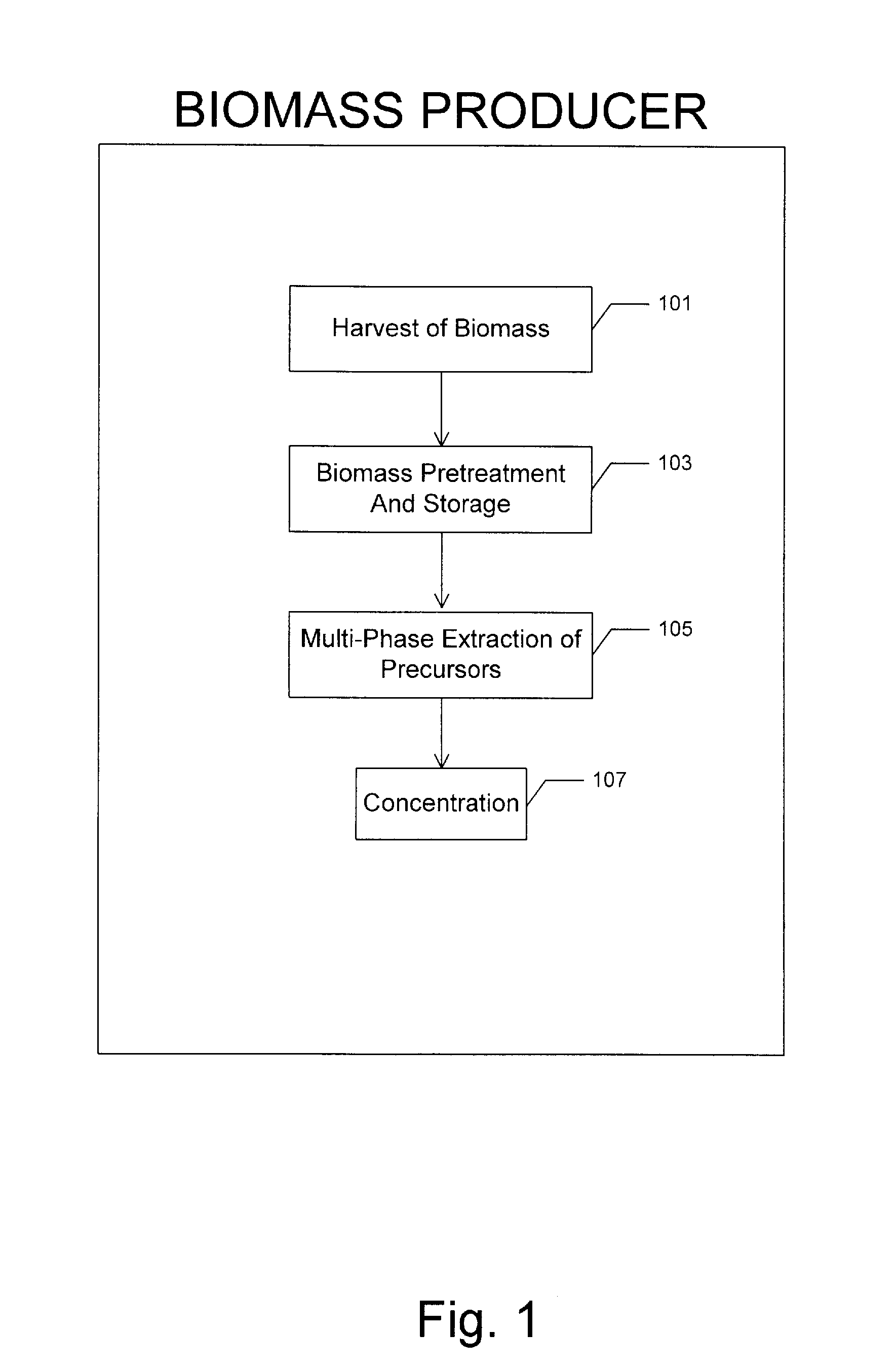

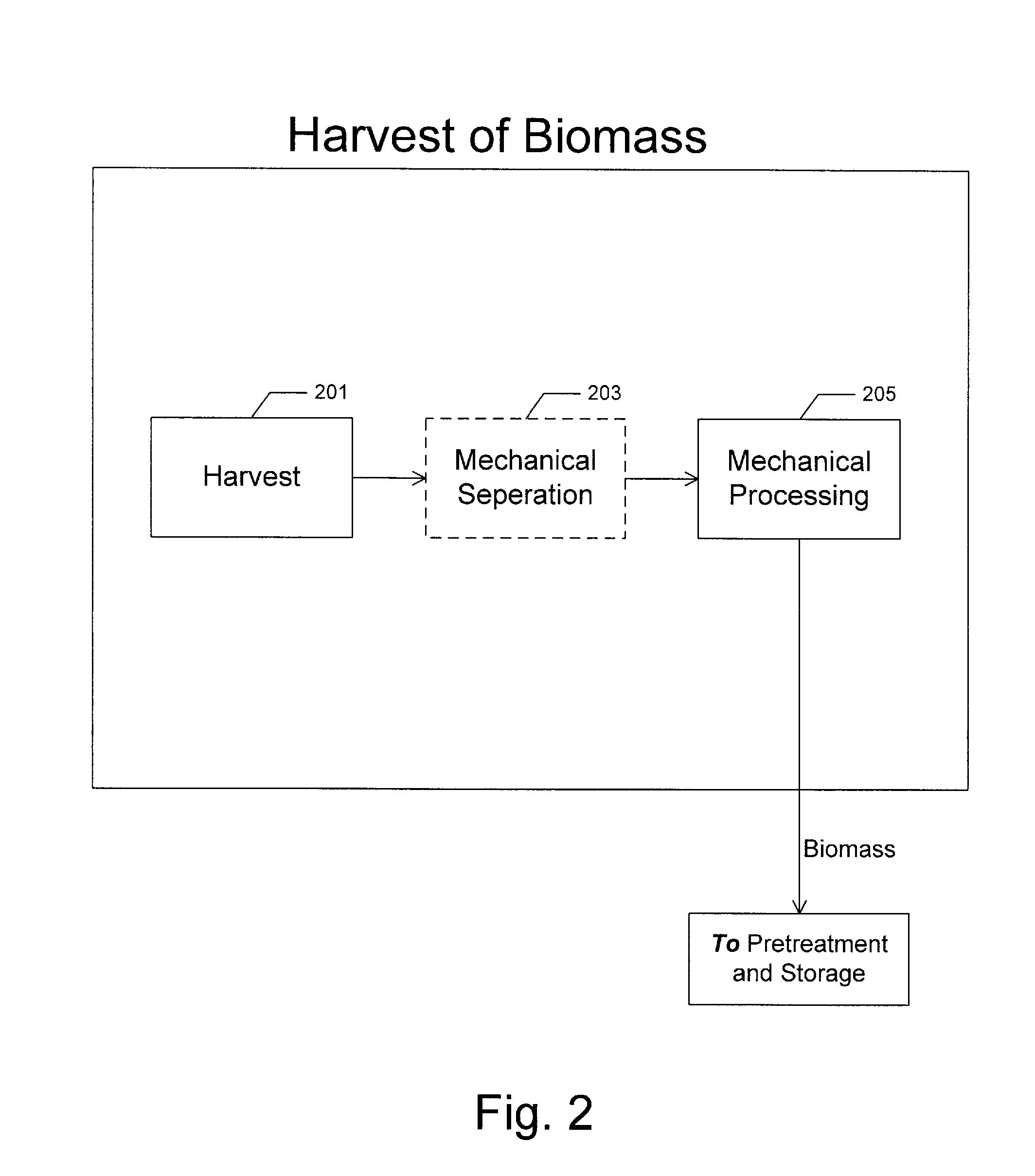

Ensiling Biomass For Biofuels Production And Multiple Phase Apparatus For Hydrolyzation Of Ensiled Biomass

ActiveUS20100144001A1Significant economic valueLower costBioreactor/fermenter combinationsBiological substance pretreatmentsChemistryDistributed source

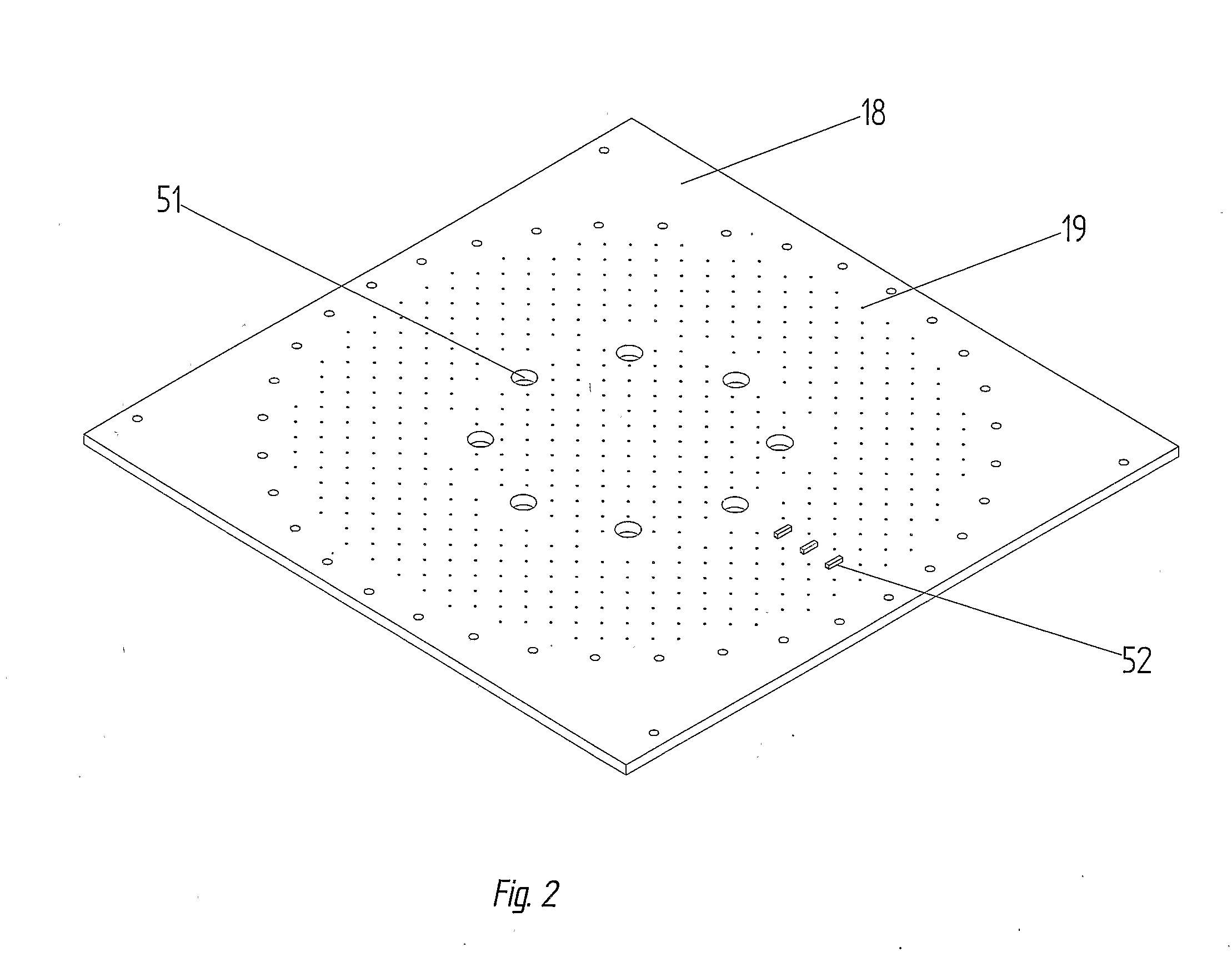

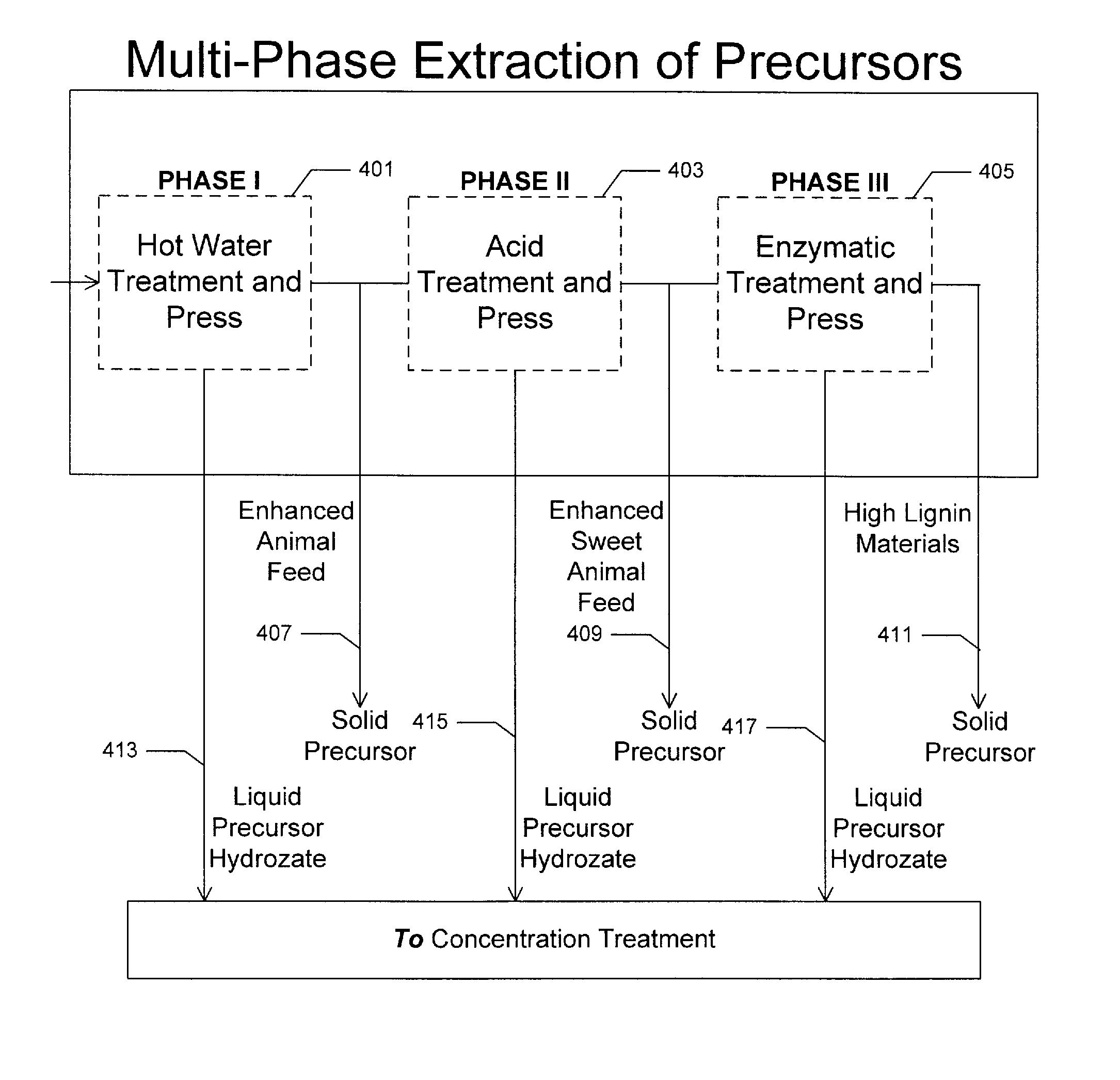

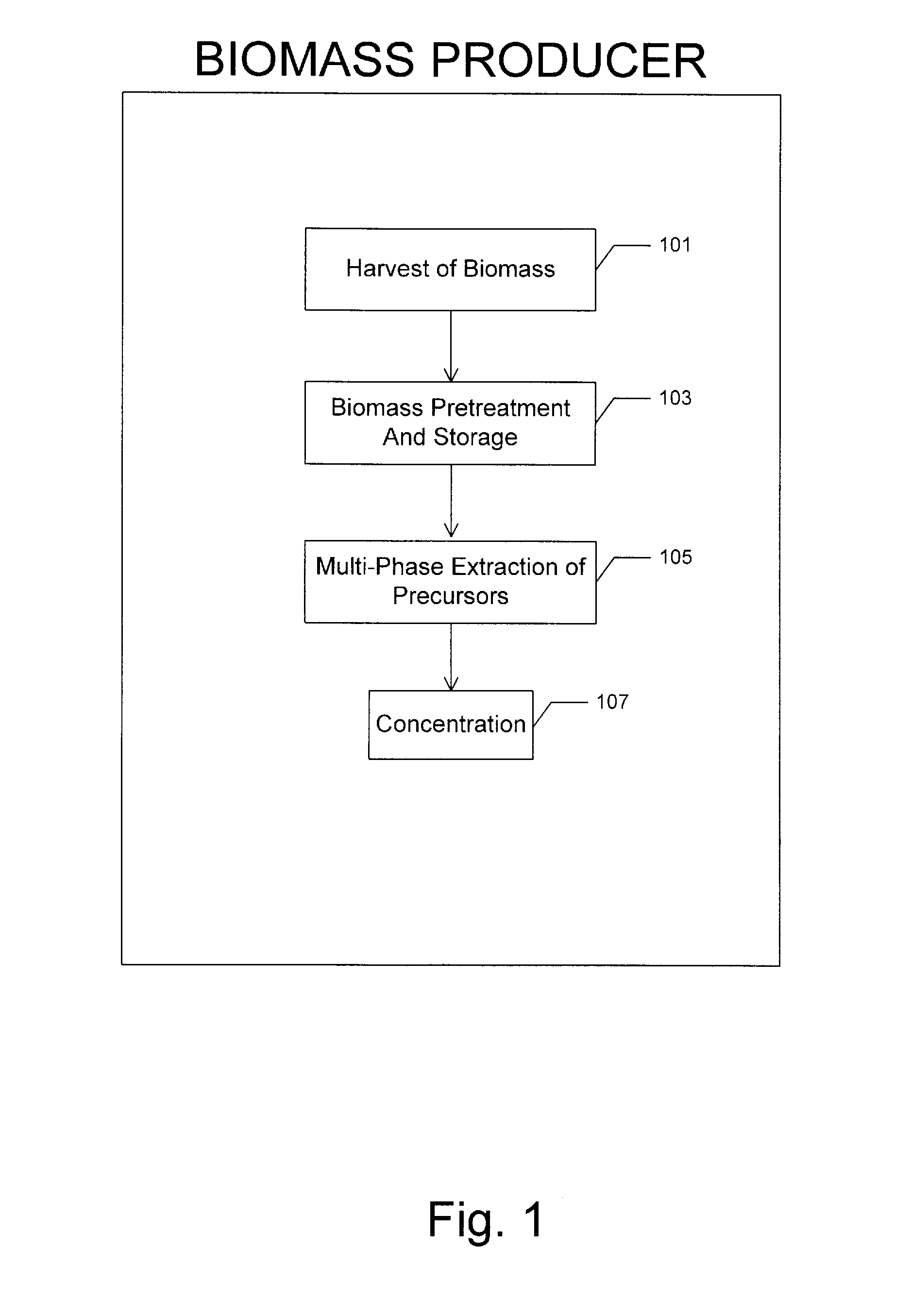

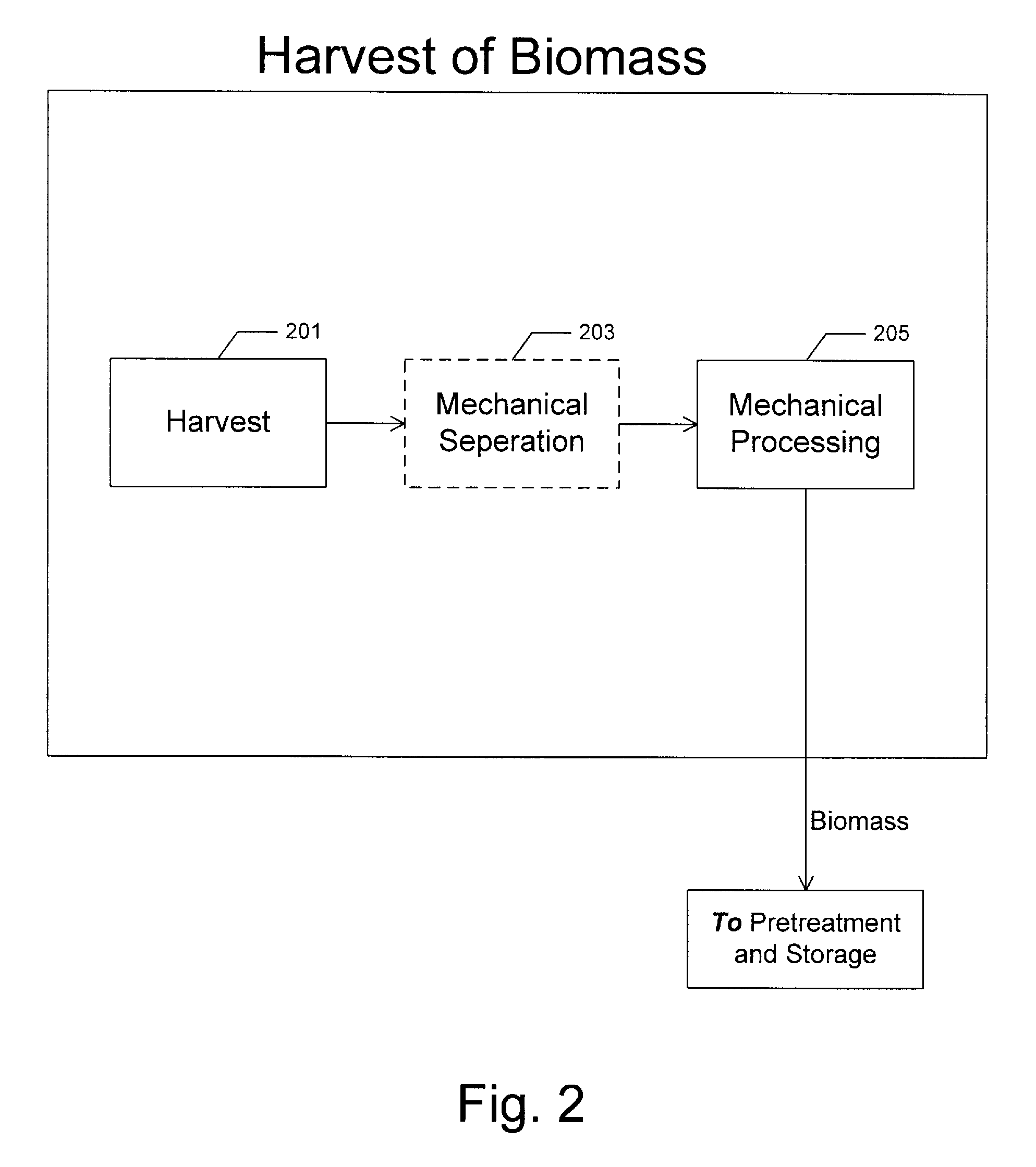

A method, apparatus and system for the hydrolyzation of ensiled biomass is disclosed. Ensiled biomass is processed in multiple phases, resulting in a liquid precursor hydrozate and a solid precursor hydrozate. The liquid precursor having significant economic value, and being suitable for uses such as, for example, lower cost and improved efficiency ethanol production. A method for lower cost, improved efficiency alcohol production that uses the resulting liquid precursor hydrozate being produced at distributed sources is further disclosed.

Owner:SWEETWATER ENERGY

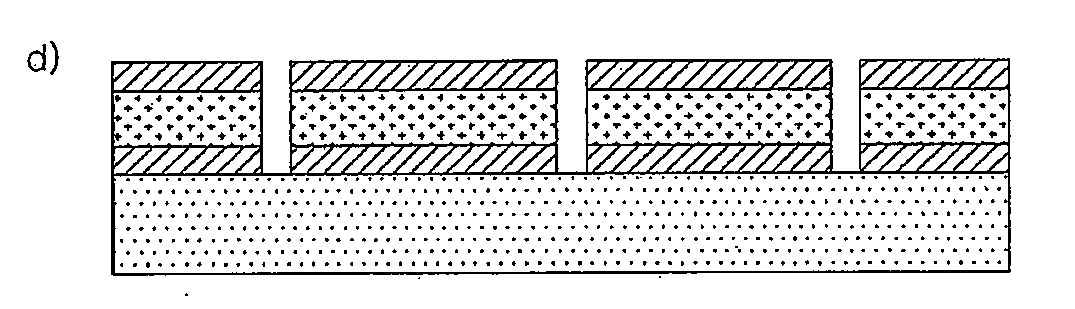

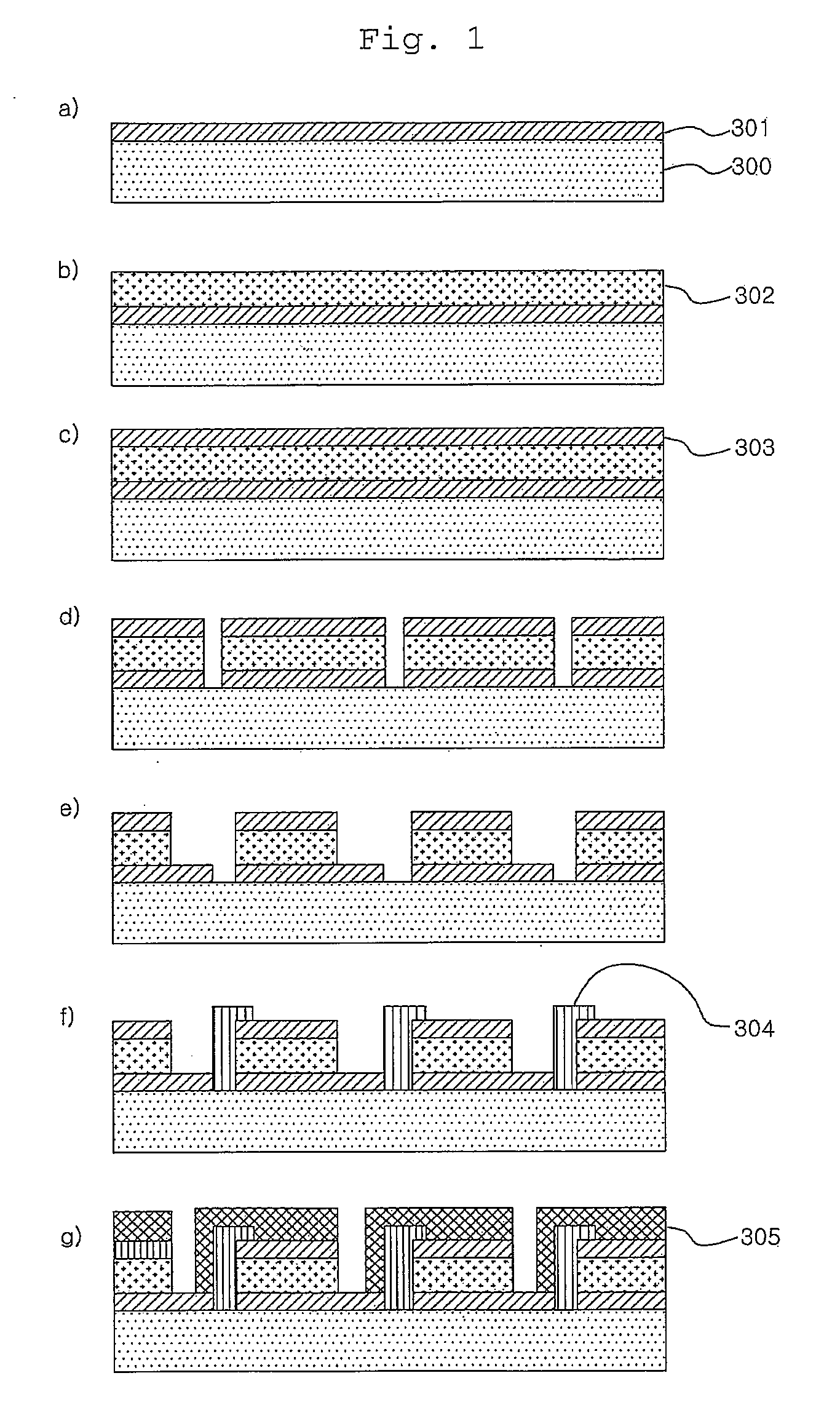

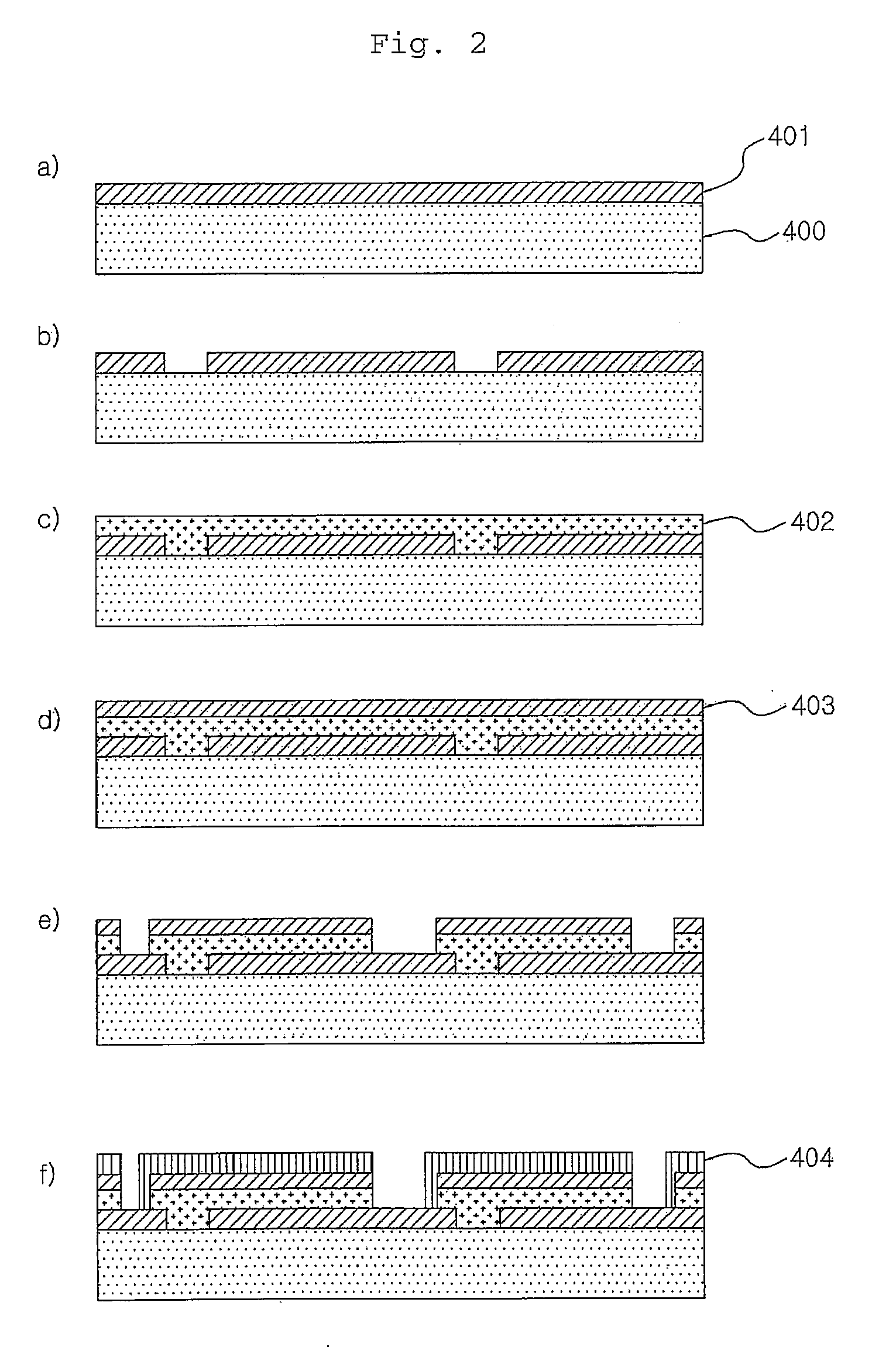

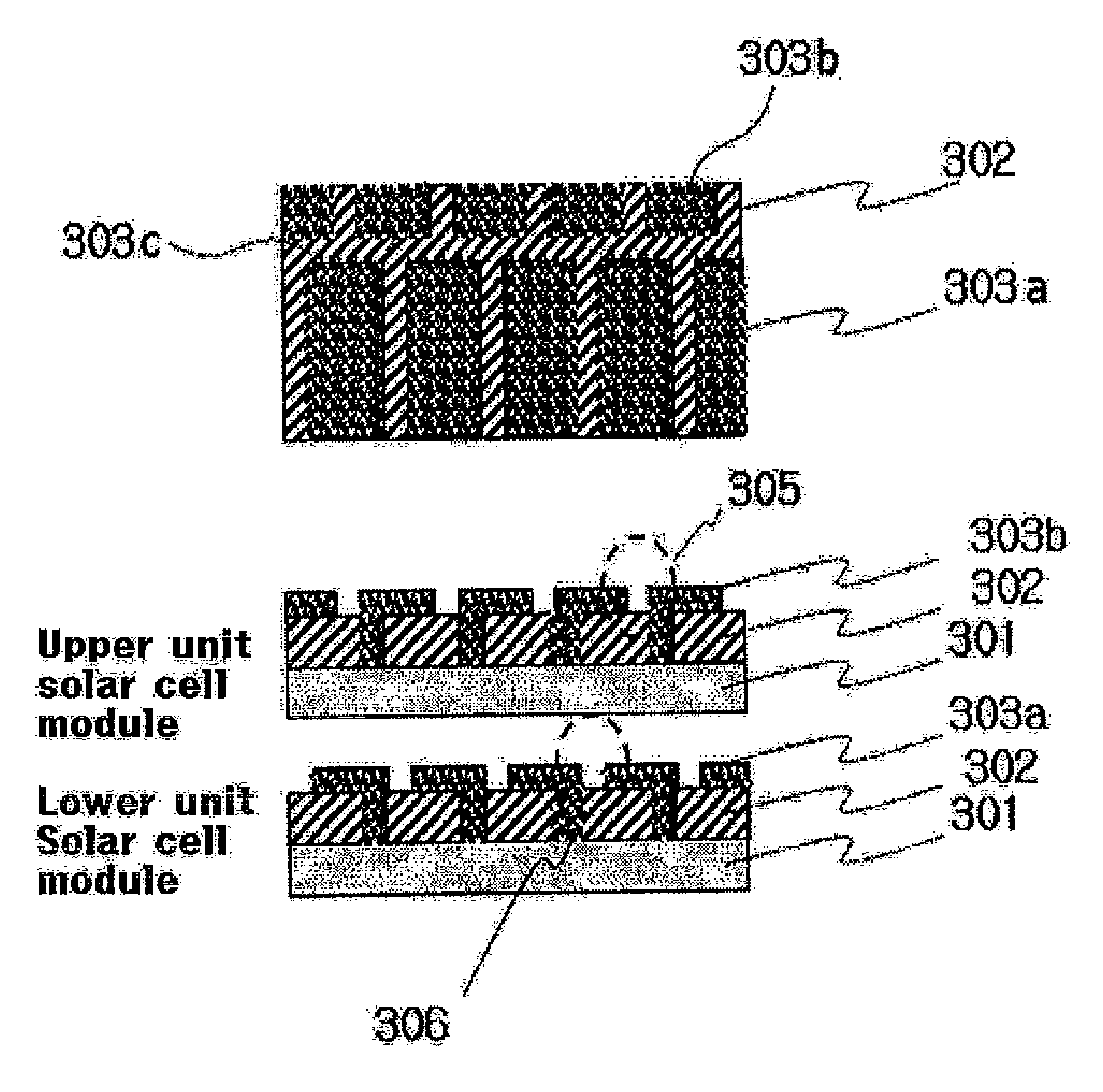

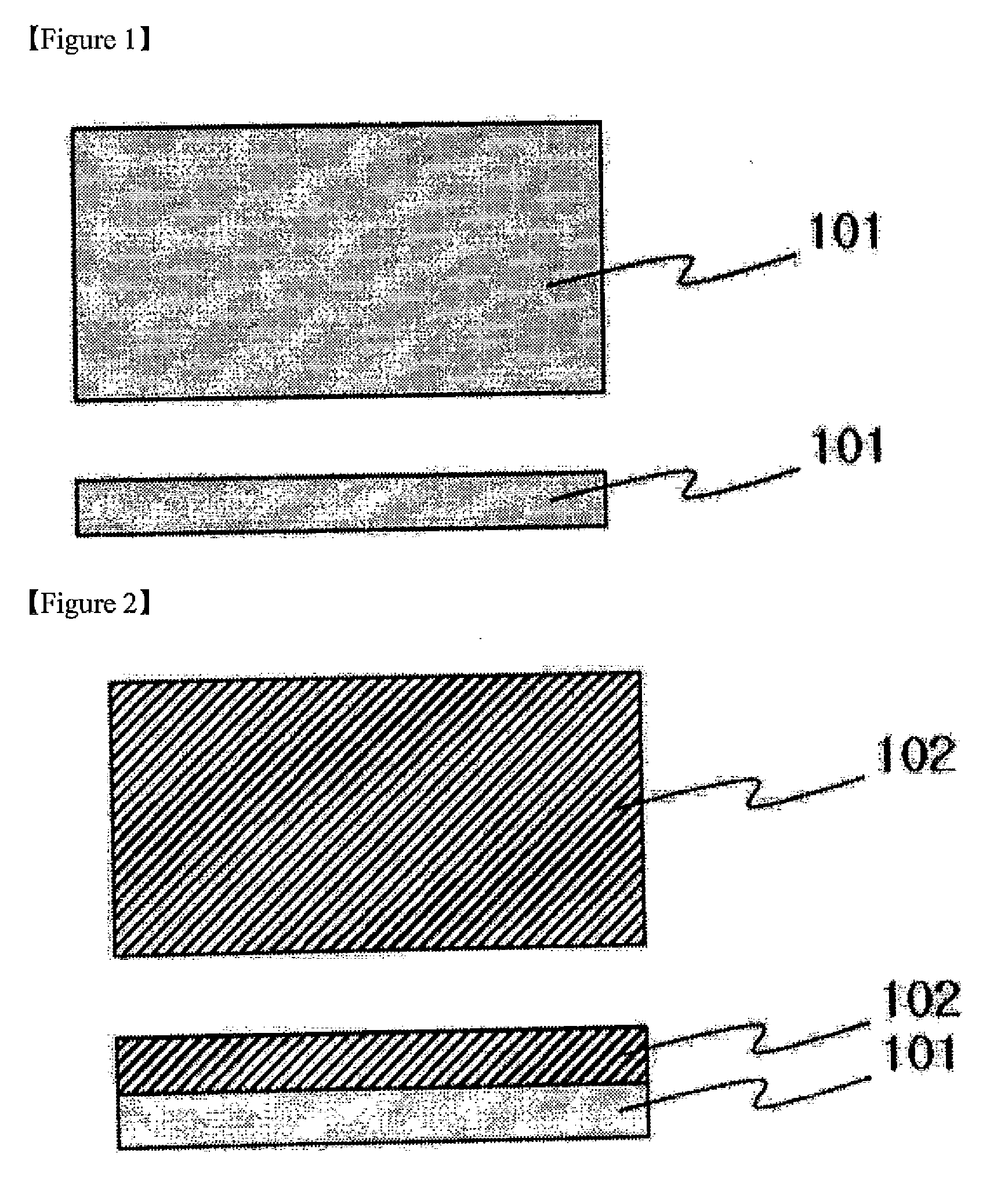

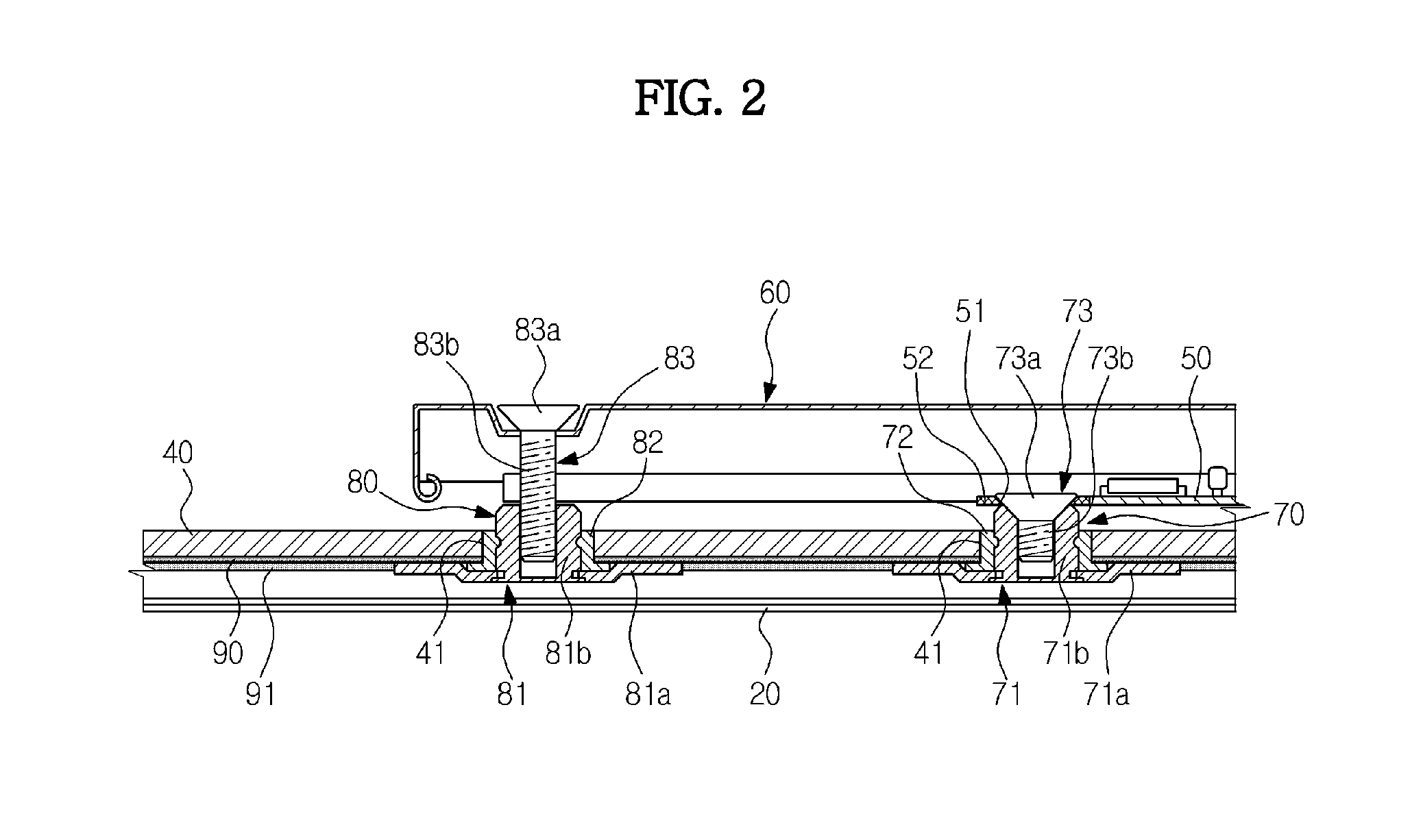

Thin-film type solar cell and method for manufacturing the same

InactiveUS20100059100A1Reduce frequencyIncrease cost reducing effectPV power plantsSemiconductor/solid-state device manufacturingEngineeringSolar cell

Disclosed are a method for manufacturing a thin-film type solar cell and a thin-film type solar cell obtained thereby that uses a direct printing method and reduces the frequency of a cutting process.

Owner:LG ELECTRONICS INC

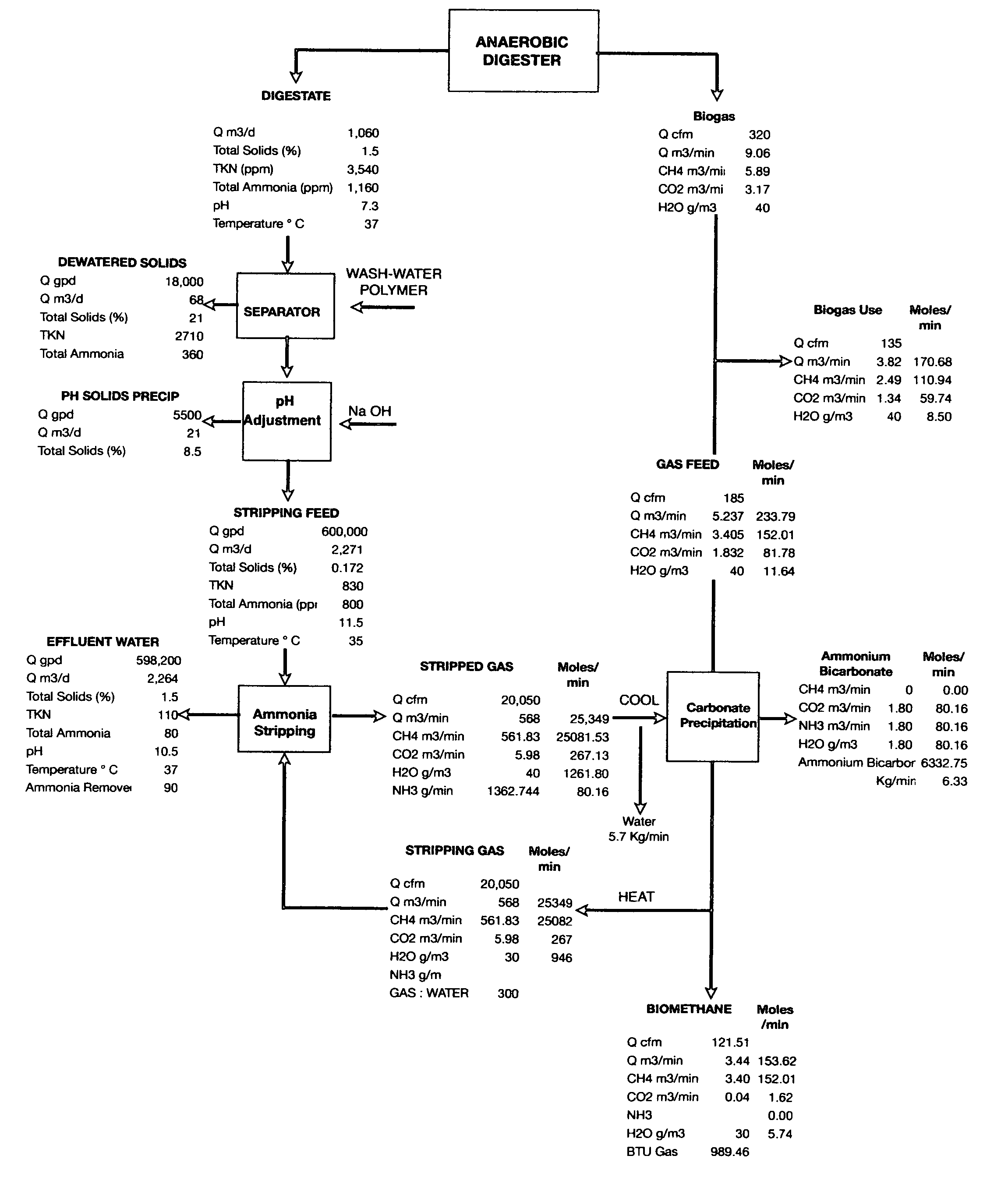

Removal of ammonia from fermentation effluent and sequestration as ammonium bicarbonate and/or carbonate

InactiveUS7811455B2High economic valueReduce fossil fuel consumptionGas treatmentCyanogen compoundsSodium bicarbonateSlurry

A method for the removal and sequestration of ammonia nitrogen from anaerobic fermentation effluent while producing a higher BTU biogas. The method includes the steps of removing the slurry from the digester, stripping the ammonia from the slurry or portion thereof with a high BTU biogas, blending the stripped ammonia with the digesters biogas to remove the carbon dioxide and precipitate ammonium bicarbonate / carbonate as a solid while producing a high Btu biogas, a portion of which is used to strip the ammonia and CO2 from the slurry. The process removes ammonia nitrogen from the digester effluent while producing a high Btu biogas and a solid ammonium bicarbonate / carbonate product. Ammonia stripping is accomplished with a recycled stripping gas deficient in CO2 and ammonia that is capable of removing the CO2 and ammonia from solution by virtue of the lower partial pressures of CO2 and ammonia in the stripping unit.

Owner:COYNE BRIAN J

Method for preventing surface of Ti-IF steel from forming crack defects

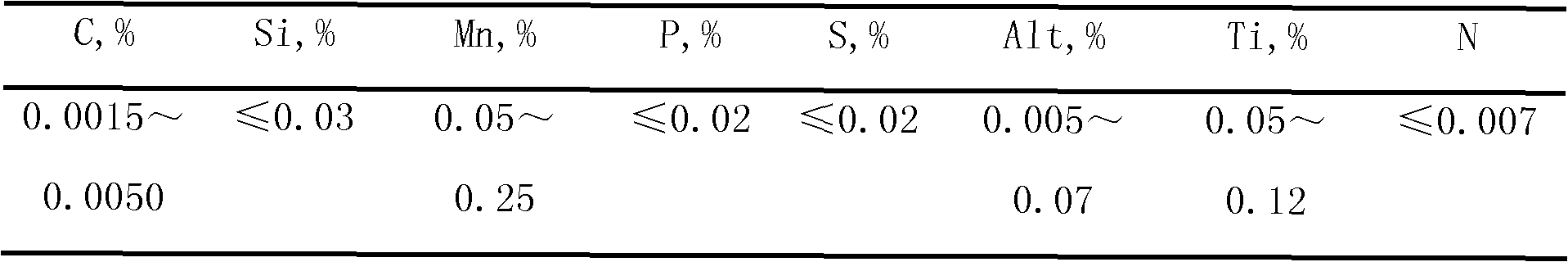

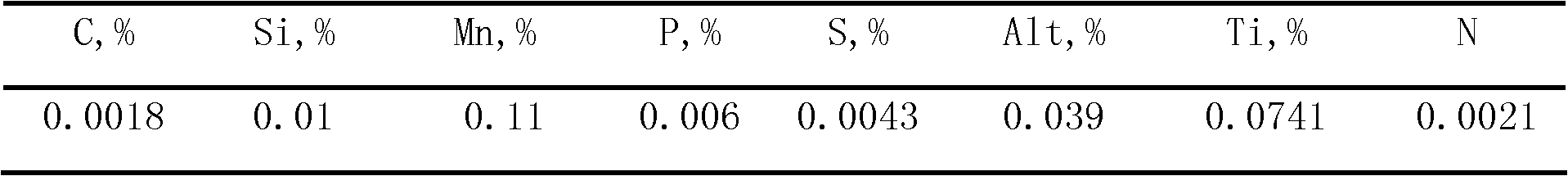

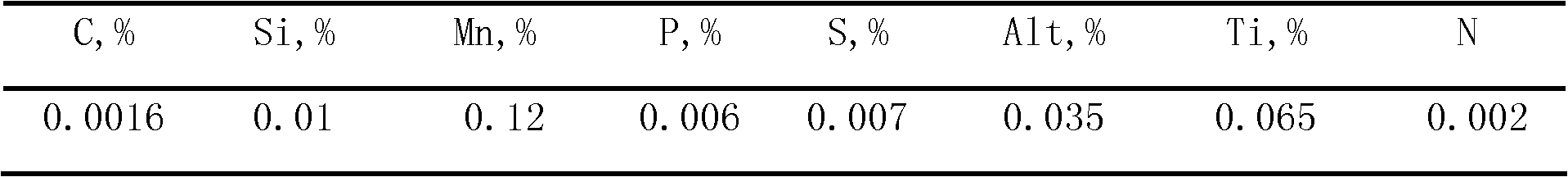

InactiveCN102154586ANo forming defectsMeet the use requirementsRoll mill control devicesMetal rolling arrangementsChemical compositionHome appliance

The invention relates to a method for preventing the surface of Ti-IF steel from forming crack defects, which belongs to the technical field of thin plate production. The method comprises the following Ti-IF steel production processes of: smelting, continuously casting, heating plate blanks, performing hot tandem rolling, reeling, performing acid tandem rolling, continuously annealing, leveling, and reeling to obtain finished products. The Ti-IF steel comprises the following components in percentage by weight: 0.0015 to 0.0050 percent of C, less than or equal to 0.03 percent of Si, 0.05 to 0.25 percent of Mn, less than or equal to 0.02 percent of P, less than or equal to 0.02 percent of S, 0.005 to 0.07 percent of Alt, 0.05 to 0.12 percent of Ti, less than or equal to 0.007 percent of N and the balance of Fe. In the rolling process, the plate blank heating temperature is between 1,200 and 1,300 DEG C; the final rolling temperature is between 890 and 920 DEG C; the reeling temperature is between 640 and 700 DEG C; the acid rolling down rate is between 70 and 80 percent; and the annealing temperature is between 760 and 850 DEG C. The invention has the advantages that: plates do not have the crack defects after being stamped and meet the using requirements of automobile shell plates and O5 plates for home appliance shell plates by rationally matching chemical components and a hot rolling process on the premise of high deep drawability; and the method has great economic value.

Owner:SHOUGANG CORPORATION

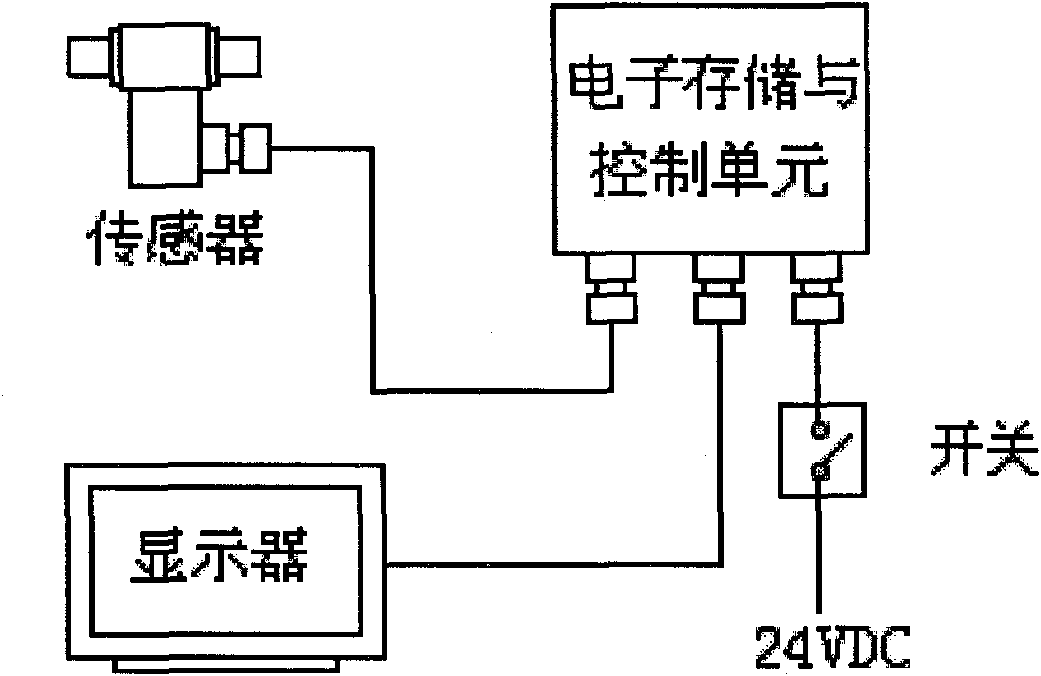

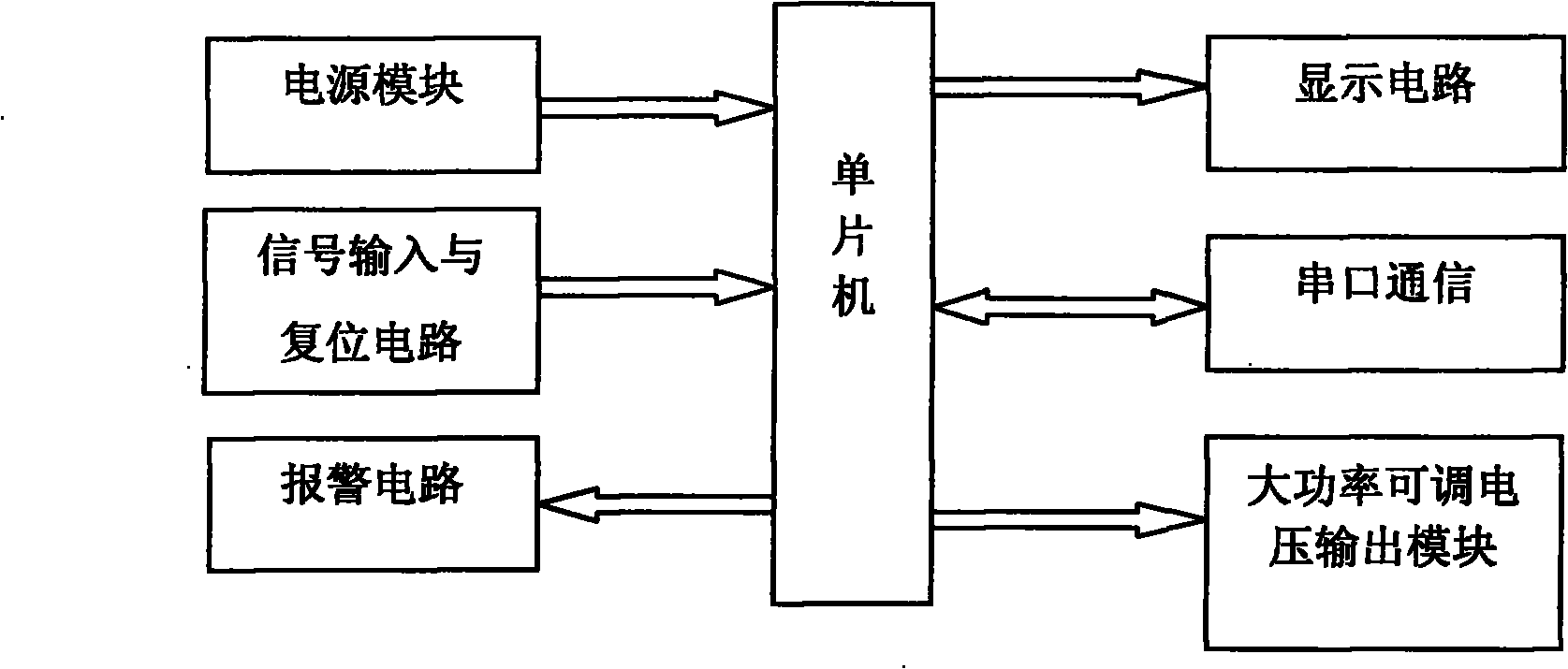

On-line monitoring plant for ferromagnetic grains in engine oil

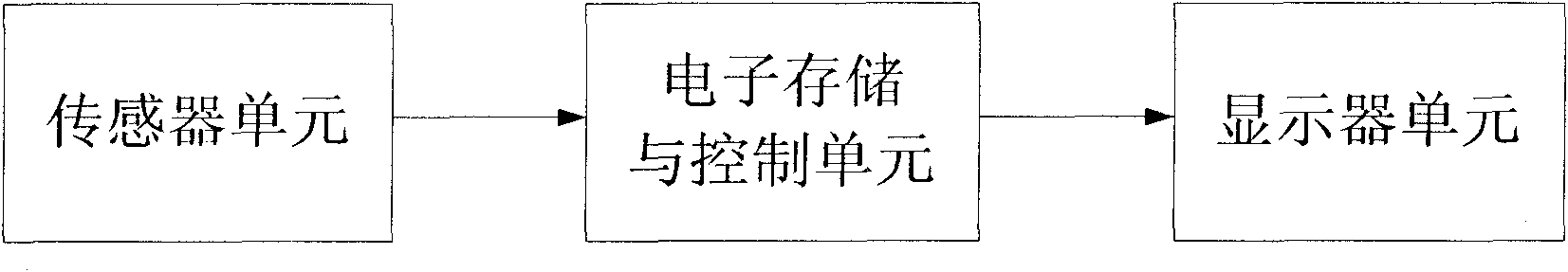

InactiveCN101806692AHelps determine remaining lifeSimple structureMaterial weighingDisplay deviceExtreme temperature

The invention discloses an on-line monitoring plant for ferromagnetic grains in engine oil, which is characterized by comprising a sensor unit, an electronic storage and control unit and a display unit, wherein the sensor unit is installed in the oil duct to be tested and adapts to the diameter of the oil duct to be tested; the electronic storage and control unit and the display unit are installed outside the oil duct to be tested; the sensor unit is connected with the electronic storage and control unit through a common cable; the electronic storage and control unit is connected with the display unit through an RS232 or RS422 / 485 series interface in common industry standard; and the display unit displays the detection values of the ferromagnetic grains in the engine oil in the on-line monitored oil duct. The plant can work in the environment of extreme temperature and vibrations, has the advantages of simple structure, convenient operation and high monitoring and response speed, and can realize prewarning of equipment failures in time. The plant is beneficial to determining the residual life of lubricating oil, optimizing the oil change period and reducing the possibility of accidents. The plant has significant economic value and is of great importance for environmental protection.

Owner:MILITARY TRANSPORTATION UNIV PLA

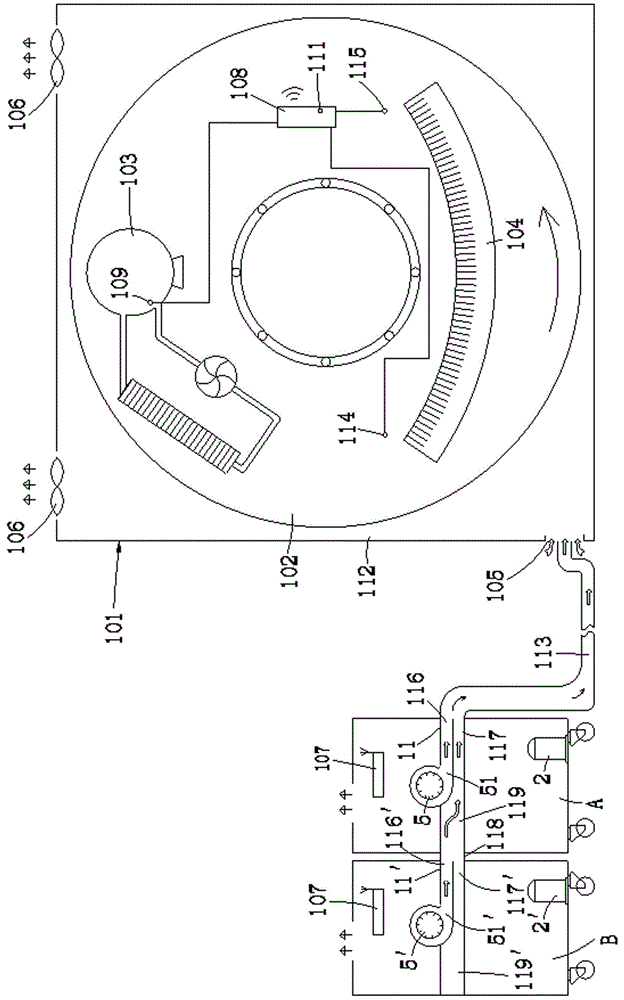

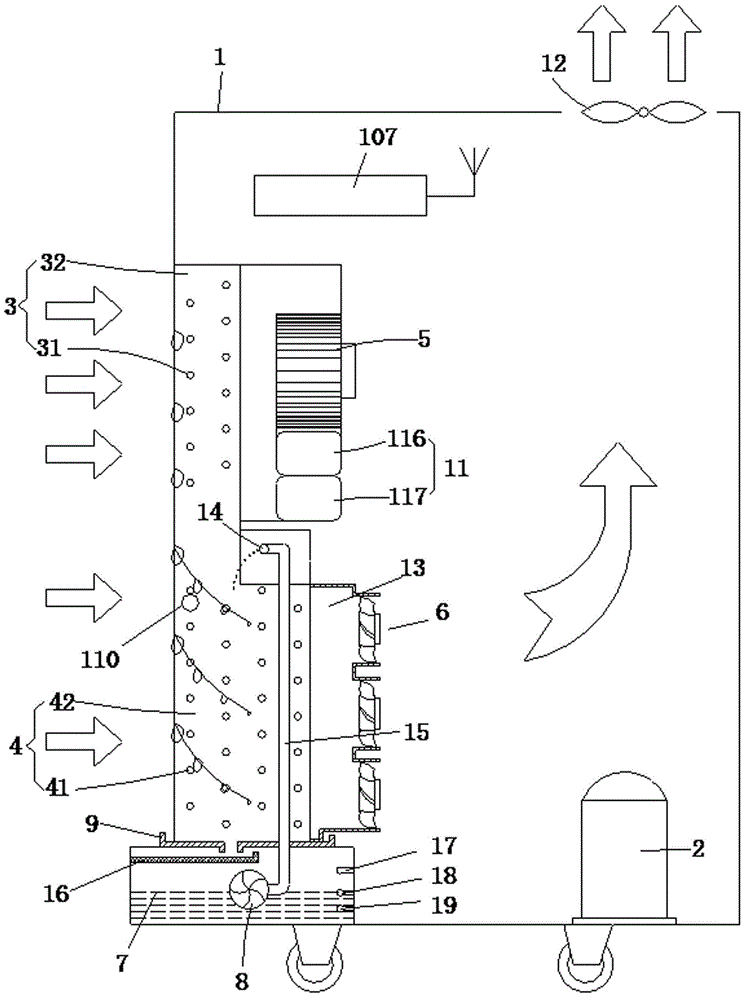

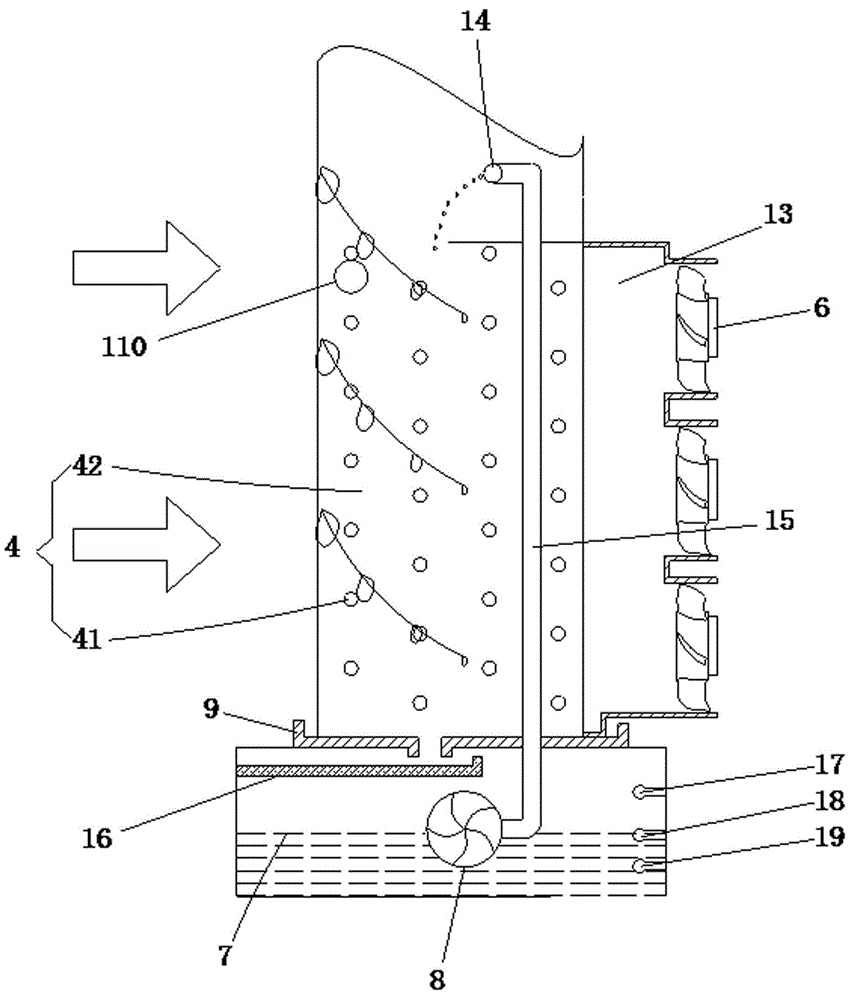

Air coolers, cooling system comprising air coolers and temperature regulating and balancing method for CT (Computed Tomography) scanning machine

InactiveCN104825184AImprove cooling efficiencyIncrease usage loadComputerised tomographsTomographyCold airComputing tomography

The invention relates to air coolers, a cooling system comprising the air coolers and a temperature regulating and balancing method for a CT (Computed Tomography) scanning machine. A plurality of negative pressure fans are arranged on the back side of a condenser of each air cooler in an array form; a condensation water tank is also arranged below the condenser; a water pump is arranged in the condensation water tank; a porous spraying pipe is arranged at the upper end of the condenser and is connected with the water pump through a pipeline; the cooling system comprises a CT scanning machine, two parallel air coolers, a receiving controller, a transmitting processor, a bulb tube temperature sensor, a condenser temperature sensor, a detector temperature sensor and a displacement sensor; a cold air outlet of the auxiliary air cooler is connected into the main air cooler through a connector and is connected with a cold air outlet of the main air cooler in parallel; the cold air outlet of the auxiliary air cooler and the cold air outlet of the main air cooler are jointly communicated with an air inlet of a rack through a cold air pipeline. According to the invention, no condensation water is stored in the air coolers, so that the energy efficiency of refrigeration is improved; the cooling system directly refrigerates a CT scanning rack, so that air temperatures of the CT bulb tube and a detector assembly in the scanning rack are reduced.

Owner:HANGZHOU SAMWAY IMAGE SCI & TECH CO LTD

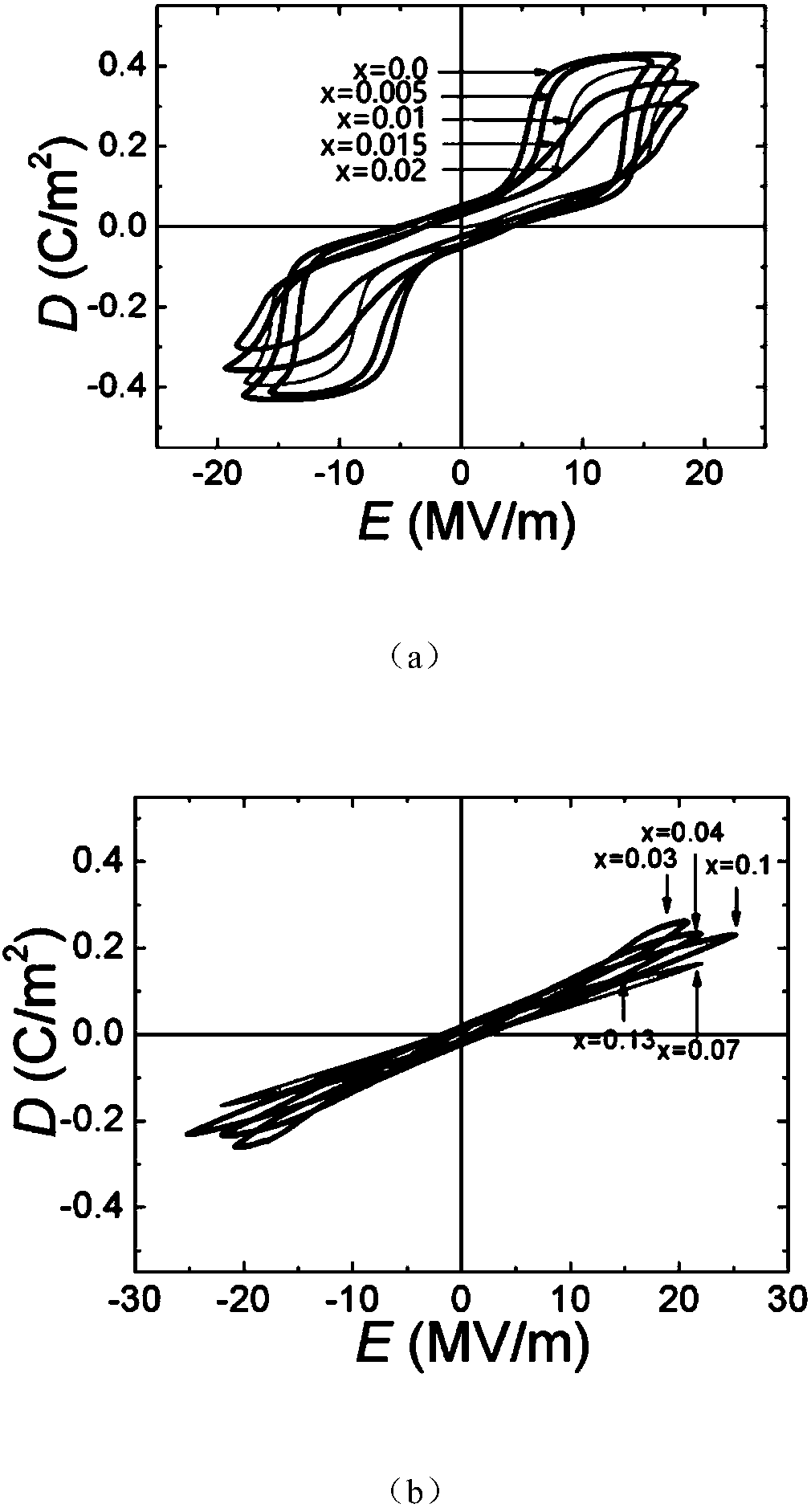

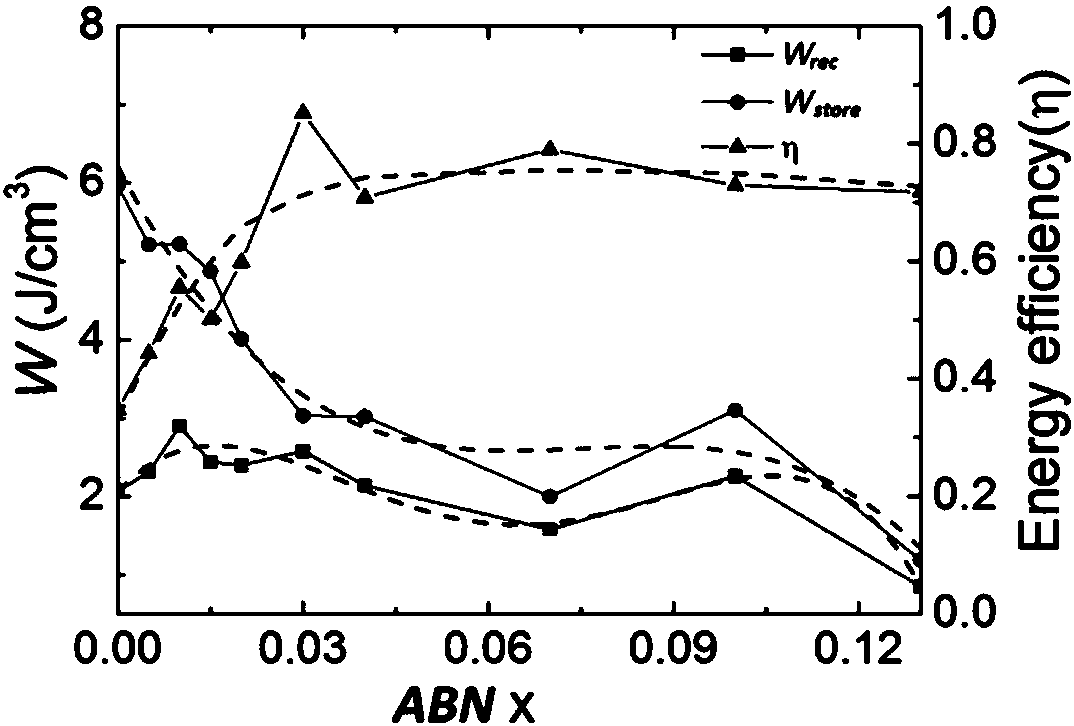

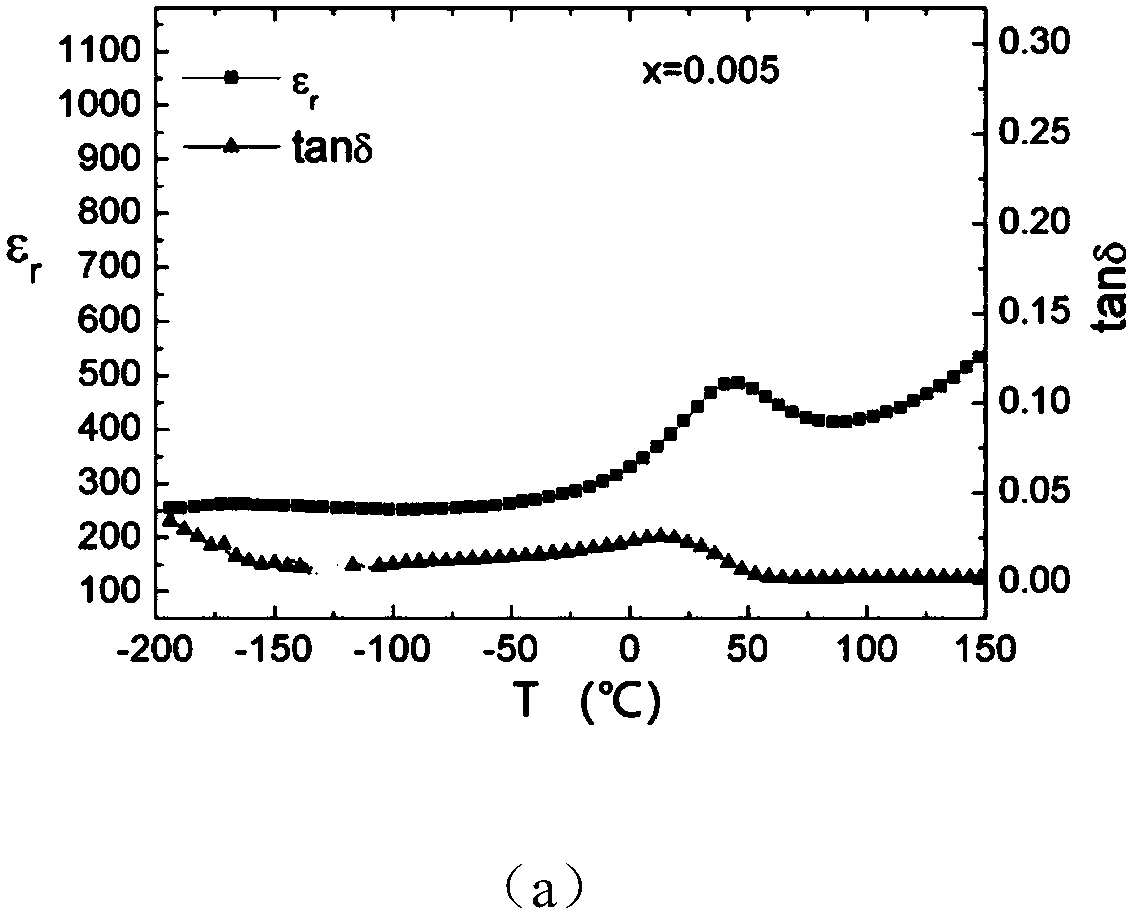

Silver niobate based anti-ferroelectric material with wide-temperature-range dielectric stability and high energy storage density and preparation method thereof

The invention discloses a silver niobate based anti-ferroelectric material with wide-temperature-range dielectric stability and high energy storage density and a preparation method thereof. The preparation method comprises the following steps: weighing silver oxide, niobium pentoxide and bismuth oxide; mixing and carrying out primary ball milling; drying, grinding and sieving a mixture obtained bythe ball milling in sequence; then pre-firing the sieved mixture; after finishing pre-firing, naturally cooling to room temperature; then carrying out secondary ball milling and drying to obtain pre-prepared powder; grinding the pre-prepared powder and sieving to obtain screened powder; then adding a polyvinyl alcohol solution into the screened powder and uniformly mixing to obtain granulated powder; then carrying out standing on the granulated powder and putting the granulated powder into a mold; pressing to obtain a blank; then sintering the blank under a pure oxygen condition; after finishing sintering, cooling and discharging to obtain a sintered ceramic sheet; after polishing the sintered ceramic sheet, airing; coating upper and lower surfaces of the sintered ceramic sheet with silver paste; then calcining; after calcining, cooling to obtain the silver niobate based anti-ferroelectric material with the wide-temperature-region dielectric stability and the high energy storage density.

Owner:XI AN JIAOTONG UNIV

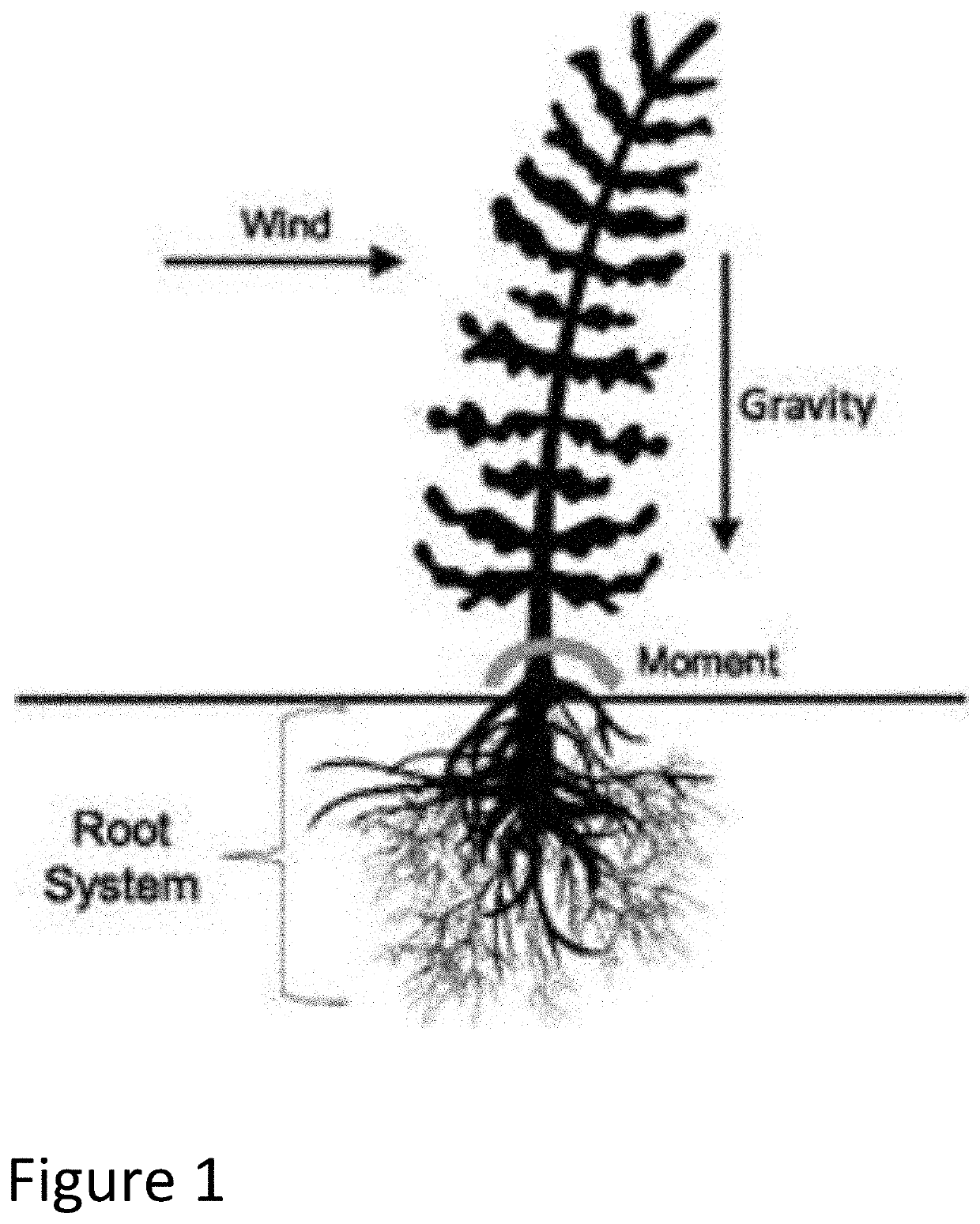

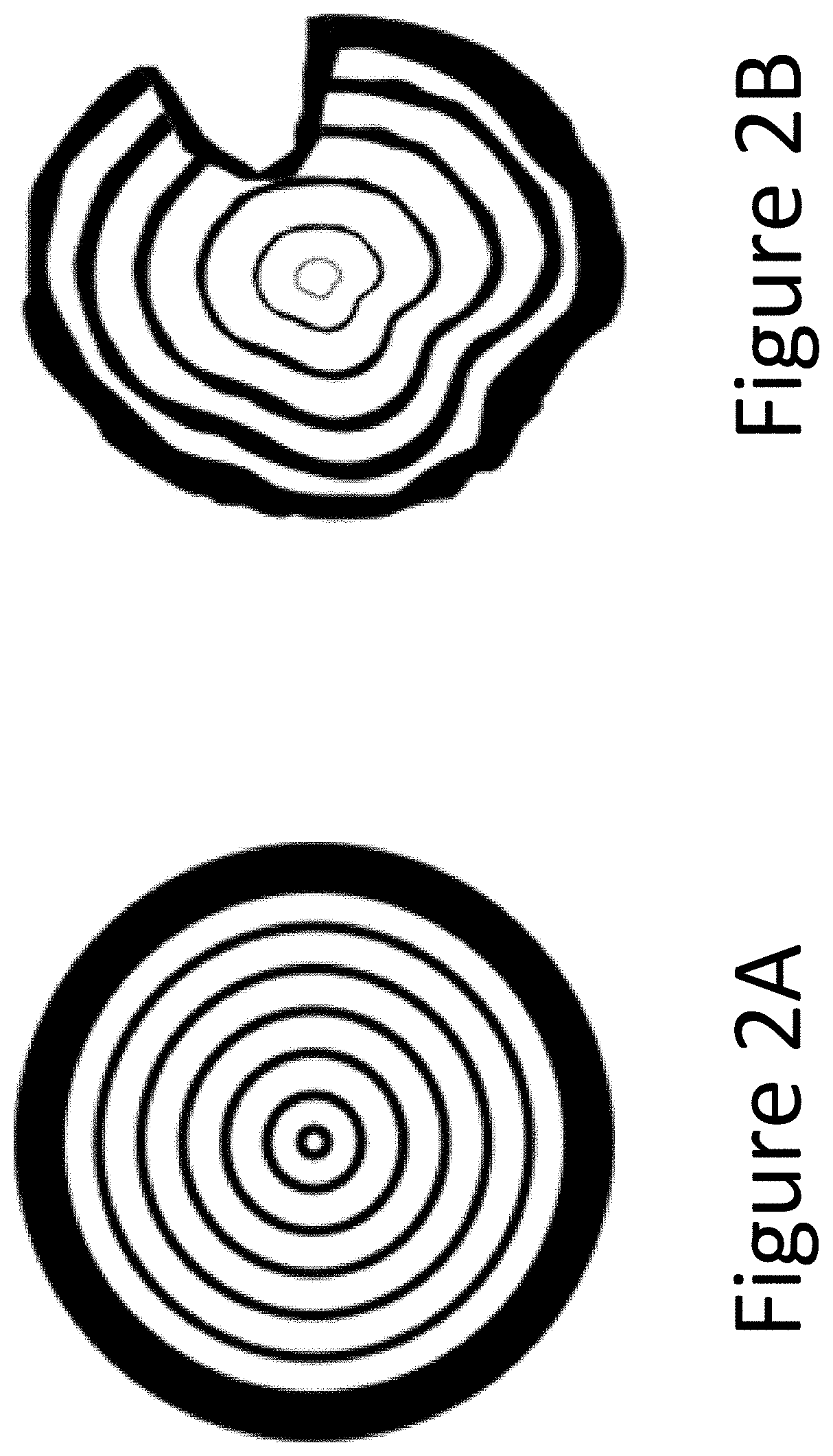

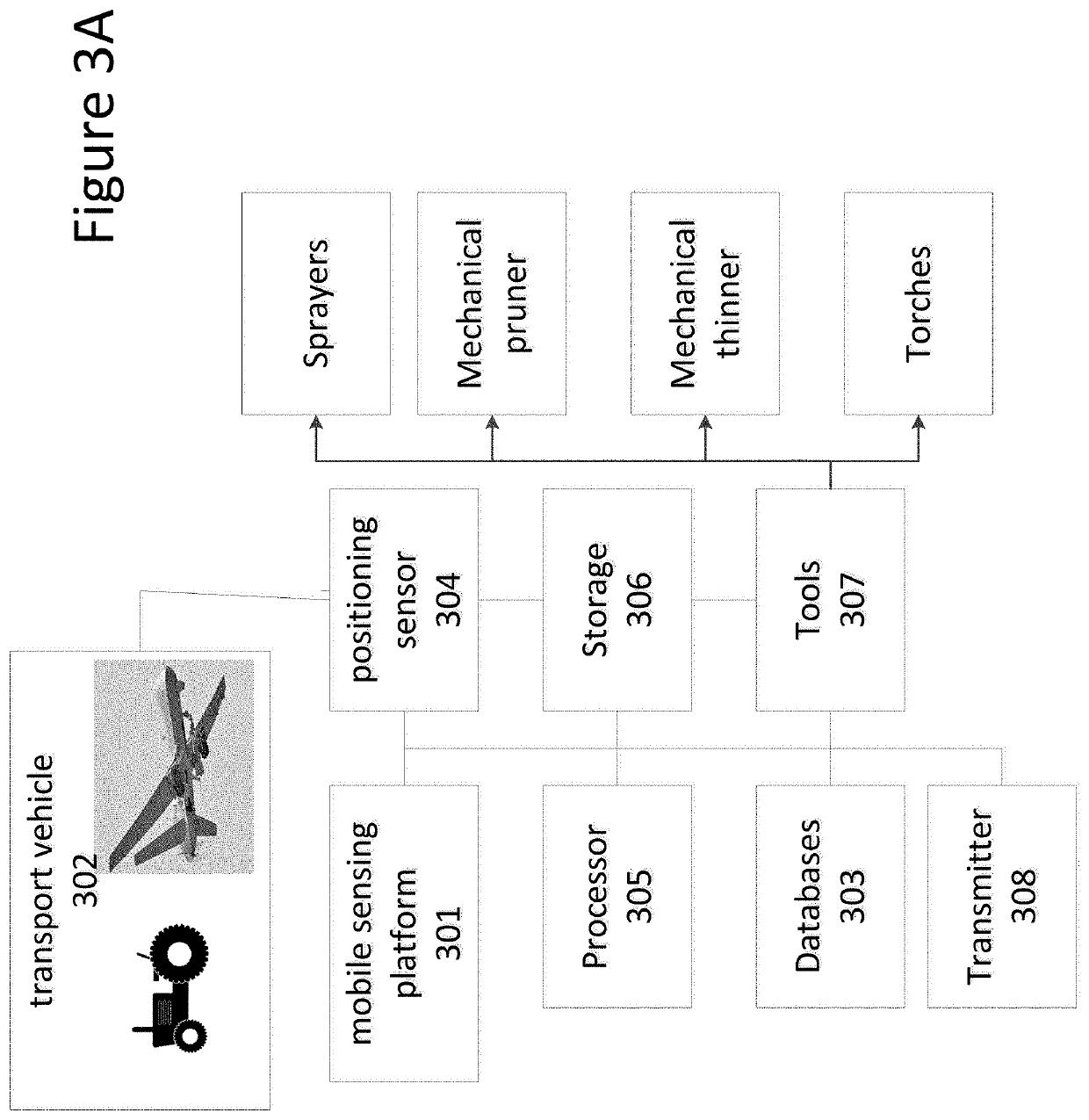

Forestry management tool for assessing risk of catastrophic tree failure due to weather events

ActiveUS20200033312A1Avoid obstaclesImprove accuracyImage enhancementImage analysisForest industryEngineering

Systems, apparatuses and methods for determining a risk of catastrophic failure for a tree based on a mechanistic model of physical characteristics of the tree are described. The systems, apparatuses and methods include a mobile sensing platform comprising one or more sensors for obtaining data, a transport vehicle configured to transport the mobile sensing platform, a positioning sensor configured to precisely calculate geographic coordinates of the positioning sensor and the location of the positioning sensor relative to a reference object as positioning data, and a processor configured to fuse the imaging data and the positioning data in order to determine conditions for catastrophic tree failure.

Owner:AGERPOINT

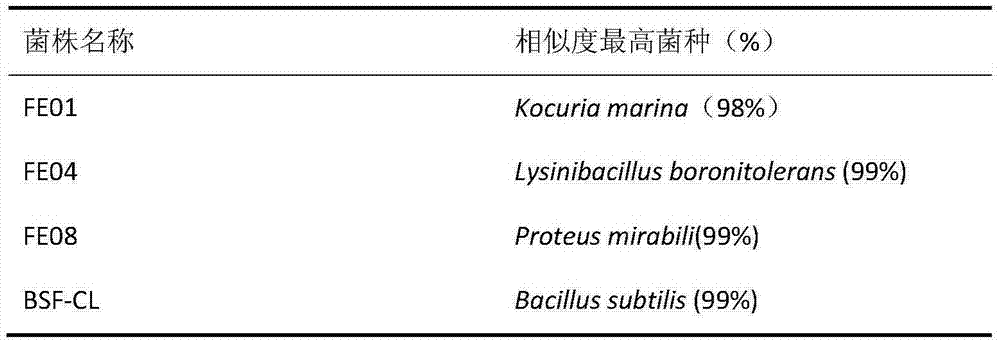

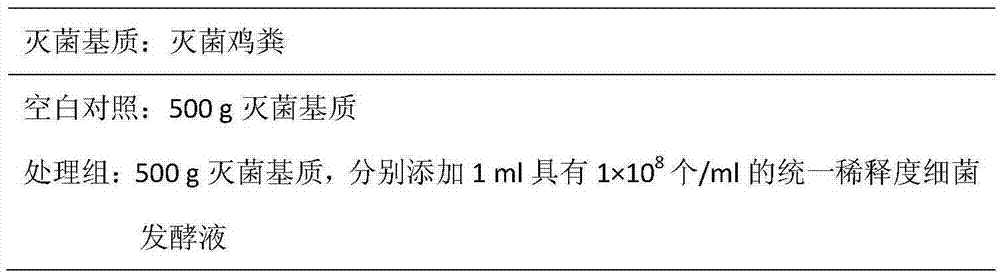

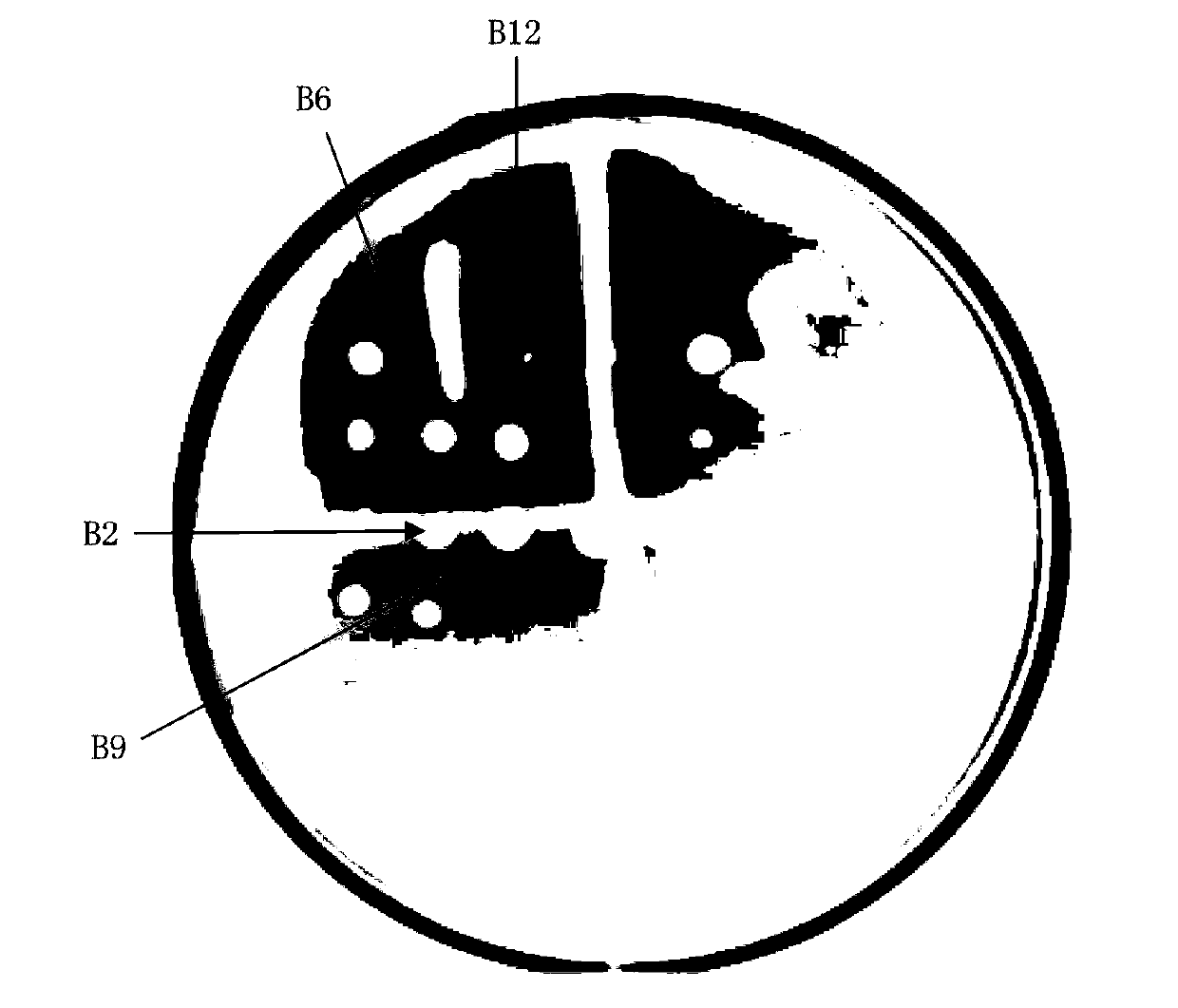

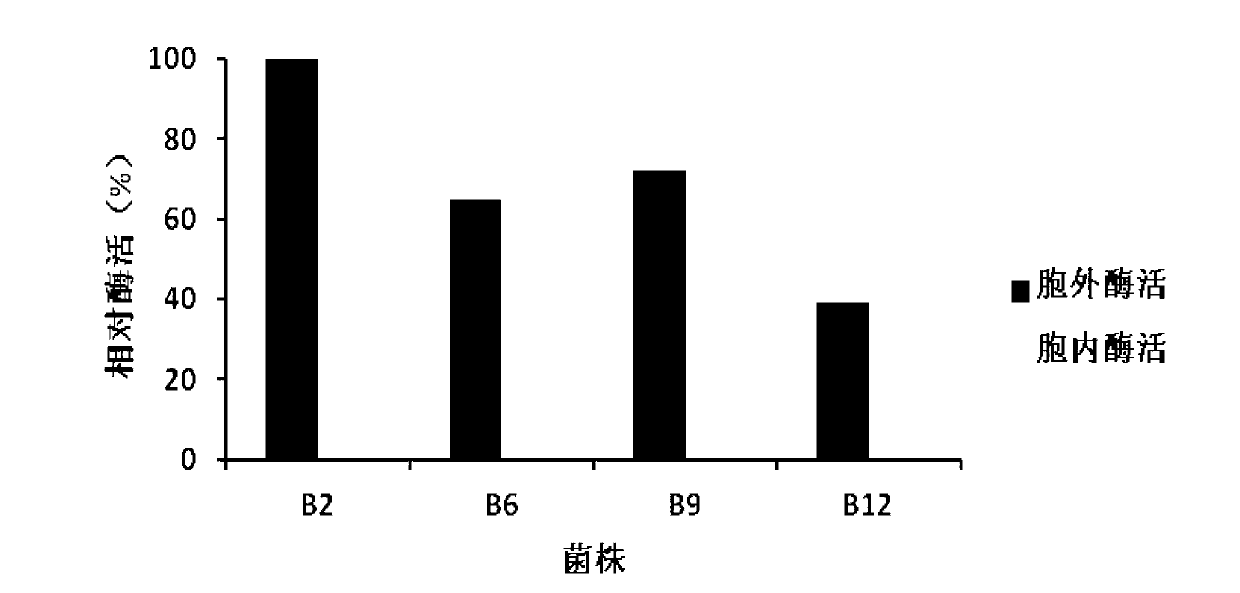

Complex microbial inoculant capable of promoting growth of larva of Hermetia illucens and application thereof

InactiveCN106854627APromote growthGain weight fastBacteriaMicroorganism based processesWeight gainingBiotechnology

The invention discloses a complex microbial inoculant capable of promoting growth of the larva of Hermetia illucens and application thereof. The complex microbial inoculant in the invention comprises Kocuria marina FE01, Lysinibacillus boronitolerans FE04, Proteus mirabilis FE08 and Bacillus subtilis BSF-CL. The complex microbial inoculant is used for promoting the growth of Hermetia illucens during transformation of chicken manure via Hermetia illucens, and is safe and environment-friendly. As the complex microbial inoculant is added into chicken manure containing Hermetia illucens, the weight gain of Hermetia illucens is increased by 28.57% compared with a chicken manure transformation system without the complex microbial inoculant; and the complex microbial inoculant can substantially improve economic benefits in large-scale chicken manure transformation via Hermetia illucens and has great economic value.

Owner:HUAZHONG AGRI UNIV

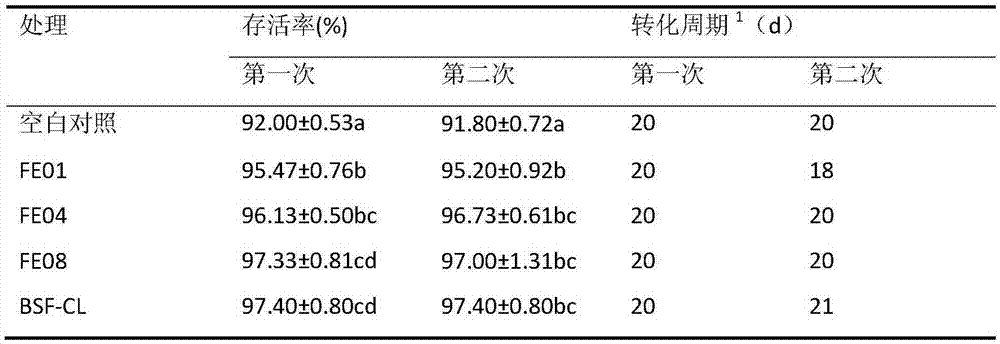

Technology for manufacturing hard alloy thin-wall shaft sleeve

The invention relates to a technology for manufacturing a hard alloy thin-wall shaft sleeve, which comprises the following processes of: A, parison machining: taking a circular steel tube or a taper steel tube as a shaft sleeve parison and trimming a size of an excircle; B, spray-welding: spray-welding a hard alloy material on the external surface of the shaft sleeve parison to form an even spray-welded layer; C, external surface machining: turning or grinding a size of an excircle of the spray-welded layer; and D, internal surface machining: cutting to remove the shaft sleeve parison by using a turning or grinding method, so as to form the hard alloy shaft sleeve. The technology for manufacturing the hard alloy thin-wall shaft sleeve, provided by the invention, is a manufacturing method which comprises the following steps of: firstly spray-welding the hard alloy material on the external surface of the shaft sleeve parison and then cutting to remove the shaft sleeve parison, so as to form the hard alloy shaft sleeve, so that the molding of small-bore thin-wall hard alloy shaft sleeves is realized, and the technical difficult problem that the small-bore thin-wall hard alloy shaft sleeves are difficult to be manufactured through a powder metallurgy molding and double-surface spray-welding method currently is solved.

Owner:自贡市巨光硬面材料科技有限公司

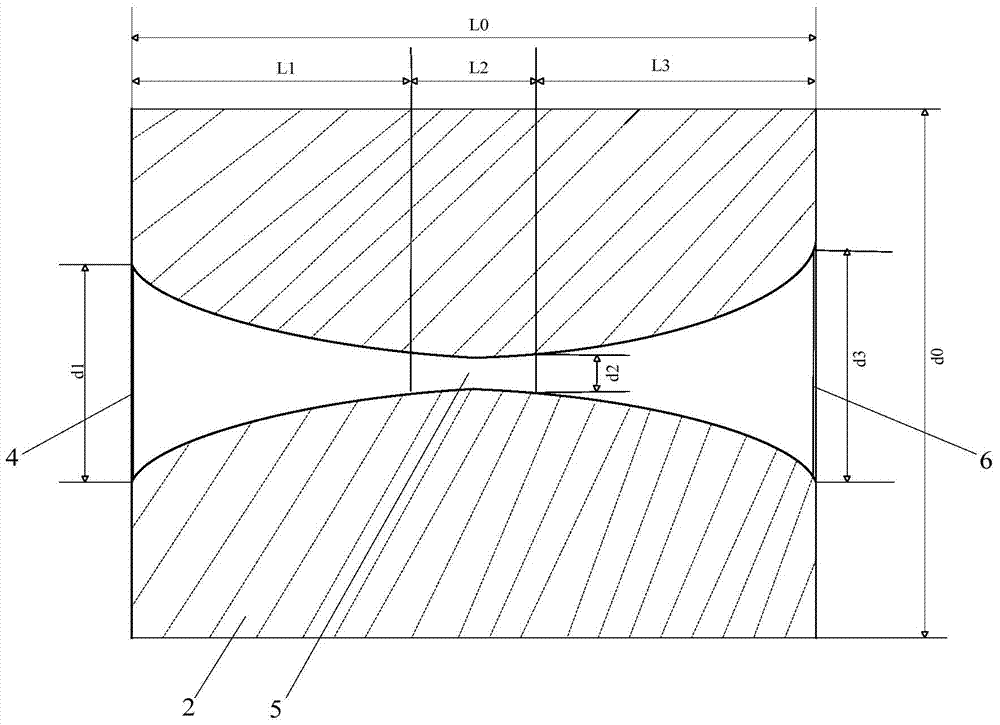

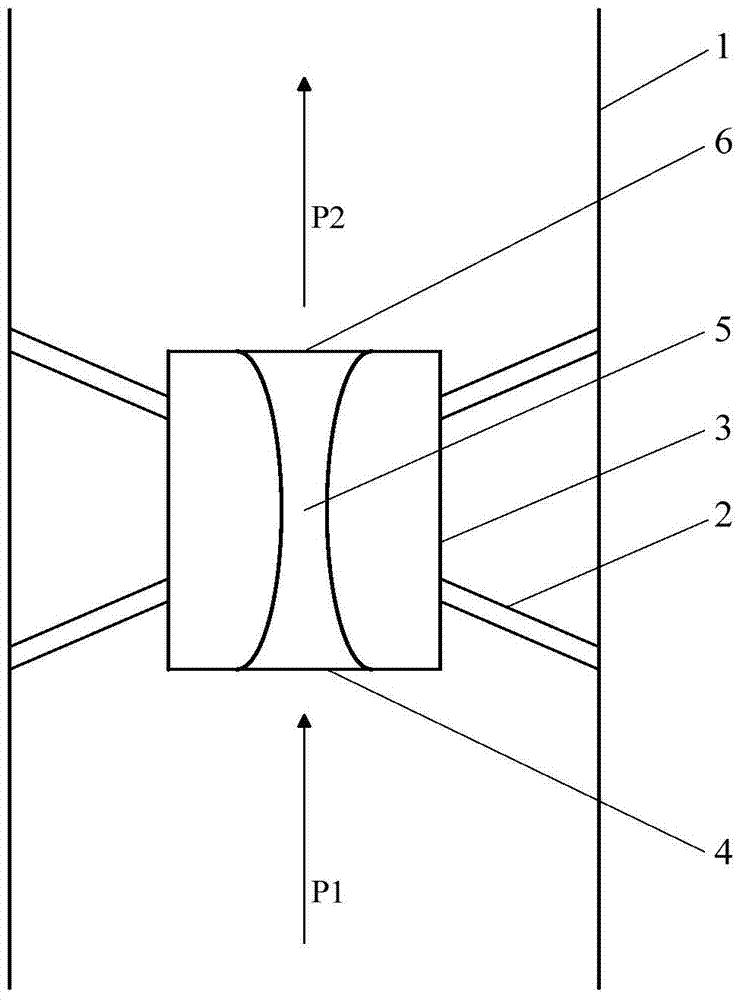

Natural gas well supersonic nozzle atomization drainage gas recovery device and method

The invention discloses a natural gas well supersonic nozzle atomization drainage gas recovery device and method. The device comprises a supersonic nozzle which is arranged on a shaft tube wall, wherein a supersonic nozzle reducing tube, a supersonic nozzle throat part and a supersonic nozzle diverging tube are arranged in the center of the supersonic nozzle from bottom to top in sequence; the supersonic nozzle is arranged on the shaft tube wall through a supersonic nozzle fixing and sealing device and is positioned on the liquid level at the bottom of a shaft. The supersonic nozzle can guarantee that natural gas in the shaft together with carried water reaches supersonic flow and the natural gas flow speed can reach 6 times of the sound speed. In the supersonic flow, the liquid is sheared and torn into extremely minor droplets; the droplets are uniformly mixed with the natural gas in an atomized manner to be discharged out of the shaft, and further the water can be continuously, stably and completely discharged by means of the energy of the natural gas. The problem of drainage gas recovery of a gas well is solved, and the device and the method have great economic value to natural gas production.

Owner:AIELEVATOR TIANJIN SCI CO LTD

Method for automated, closed loop cleaning of tanks

InactiveUS20130247939A1Significant economic valueEasy to cleanHollow article cleaningCleaning using gasesLand basedClosed loop

A method for cleaning tanks and other containers including, but not necessarily limited to, tanks associated with land-based drilling rigs and / or used in connection with hydraulic fracturing operations. Recoverable liquids and associated solids are first removed from a tank to be cleaned. A cleaning solution is prepared in a weir tank and sprayed into a tank to be cleaned. Sprayed cleaning solution, together with any debris or residue from the tank being cleaned, is pumped back to the weir tank and recycled for further cleaning.

Owner:CHANTHAVONGSY PEAK +1

Ensiling biomass for biofuels production and multiple phase apparatus for hydrolyzation of ensiled biomass

ActiveUS8529765B2Significant economic valueImprove efficiencyBioreactor/fermenter combinationsPressurized chemical processDistributed sourceAlcohol production

A method, apparatus and system for the hydrolyzation of ensiled biomass is disclosed. Ensiled biomass is processed in multiple phases, resulting in a liquid precursor hydrozate and a solid precursor hydrozate. The liquid precursor having significant economic value, and being suitable for uses such as, for example, lower cost and improved efficiency ethanol production. A method for lower cost, improved efficiency alcohol production that uses the resulting liquid precursor hydrozate being produced at distributed sources is further disclosed.

Owner:SWEETWATER ENERGY INC

All-solid-waste foam concrete and preparation method thereof

ActiveCN112811858ASmall particle sizePromote dissolutionCement productionCeramicwareFoam concreteCompressive resistance

The invention relates to all-solid-waste foam concrete and a preparation method thereof. The concrete comprises the following raw material components in percentage by mass: 6-12% of wet-milled superfine slag, 18-30% of slag, 4-10% of a compound activator, 32-40% of iron tailings, 4.65-5.27% of a compound foaming agent, 0.078-0.082% of a compound foam stabilizer and the balance of water. The light-weight and high-strength all-solid-waste foam concrete is prepared from the wet-ground superfine slag, the phosphogypsum, the steel slag, the iron tailings and other solid wastes as main raw materials under the action of the compound foaming agent and the compound foam stabilizer, the dry density grade of the provided all-solid-waste foam concrete can reach A06, the 28d compressive strength grade can reach C3.0, and the development requirements of light weight and high strength of the foam concrete are met.

Owner:WUHAN UNIV OF TECH

Ensiling Biomass for Biofuels Production and Multiple Phase Apparatus for Hydolyzation of Ensiled Biomass

InactiveUS20130323830A1Significant economic valueImprove efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsDistributed sourceAlcohol production

A method, apparatus and system for the hydrolyzation of ensiled biomass is disclosed. Ensiled biomass is processed in multiple phases, resulting in a liquid precursor hydrozate and a solid precursor hydrozate. The liquid precursor having significant economic value, and being suitable for uses such as, for example, lower cost and improved efficiency ethanol production. A method for lower cost, improved efficiency alcohol production that uses the resulting liquid precursor hydrozate being produced at distributed sources is further disclosed.

Owner:SWEETWATER ENERGY INC

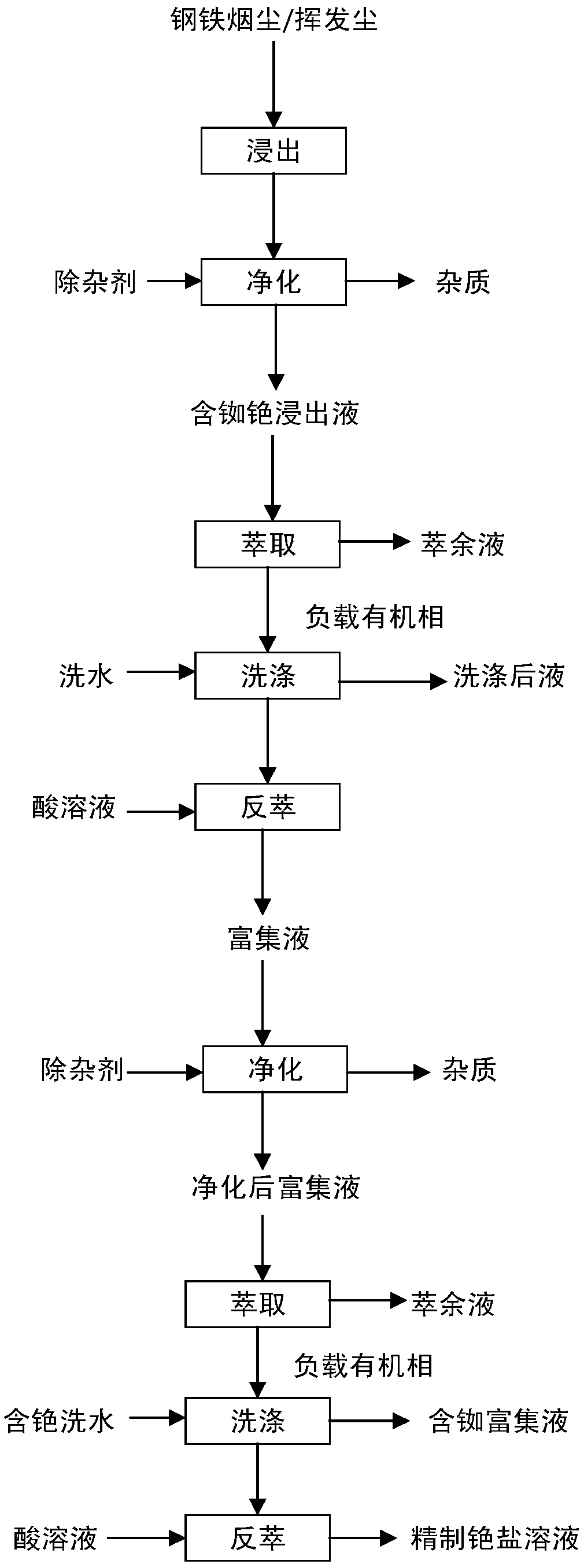

Method for extracting rubidium and cesium from steel soot and/or volatile dust

ActiveCN110835687AAchieve recyclingLarge amount of resourcesProcess efficiency improvementRubidiumSolvent

The invention provides a method for extracting rubidium and cesium from steel soot and / or volatile dust. The method comprises the steps that (1), the steel soot and / or volatile dust and a solvent aremixed to obtain a solution containing rubidium and cesium, purification is carried out through a purifying agent, and leach liquor containing rubidium and cesium is obtained; (2), an extracting agentis used for carrying out extracting on the leach liquor containing rubidium and cesium, rubidium and cesium in a load organic phase are stripped into water through an acidic material, and enrichment liquor is obtained; (3), the enrichment liquor is purified through the purifying agent, and purified enrichment liquor is obtained; and (4), extraction is carried out on the purified enrichment liquorthrough the extracting agent, the load organic phase is washed to remove rubidium through an aqueous solution, then cesium in the washed and rubidium-removed load organic phase is stripped into the aqueous phase through the acidic material, a cesium salt solution is obtained, and residual liquor after extraction and / or a washing water phase are / is a rubidium-rich solution. By means of the method,existing rubidium and cesium resource quantity is greatly expanded, a specific enrichment and purification technology is established, and significant economic value is achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

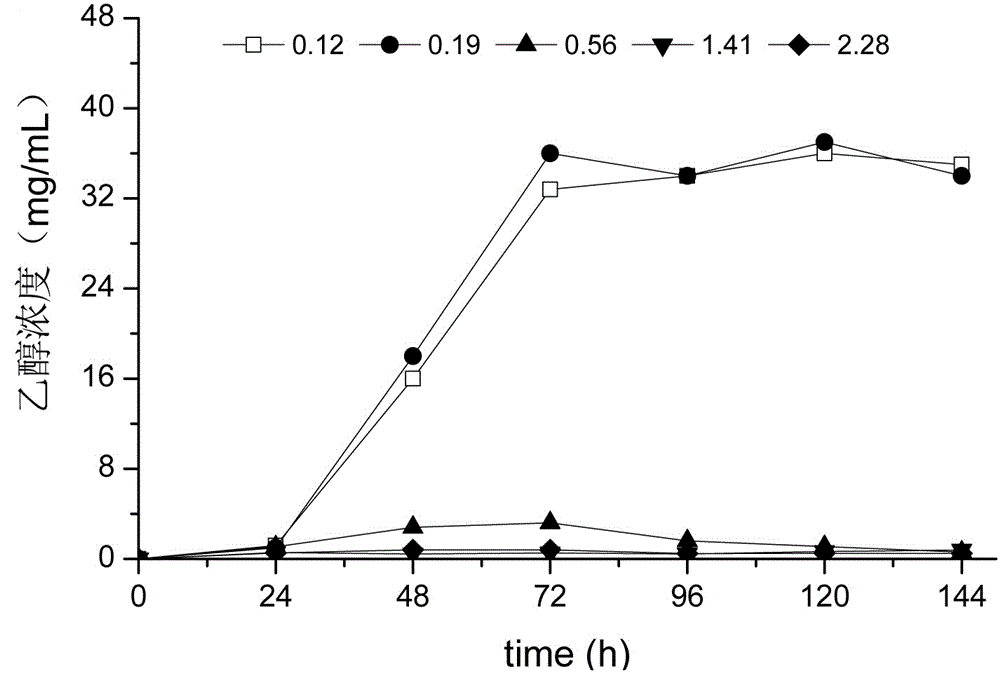

Bacterial strain capable of realizing high yield of L-alanine

InactiveCN106047740AIncrease productionImprove stabilityBacteriaMicroorganism based processesEscherichia coliSerial passage

The invention provides a bacterial strain capable of realizing high yield of L-alanine, belonging to the field of bioengineering technology. The bacterial strain capable of realizing high yield of L-alanine is named as Escherichia coli (EcQLS1) with an accession number of CGMCC No. 1764. The Escherichia coli (EcQLS1) strain is obtained through a combination of normal-temperature normal-pressure plasma mutation and high-flux screening, can greatly improve the yield of L-alanine and has good stability, wherein the yield of L-alanine has no obvious change after serial passage of the strain for five generations. Results of shake-flask experiments show that the yield of L-alanine reaches 120 g / L. The bacterial strain provided by the invention totally meets industrial mutation and screening demands on an L-alanine strain, is applicable to industrial fermentation production and has significant economic value.

Owner:QILU UNIV OF TECH +1

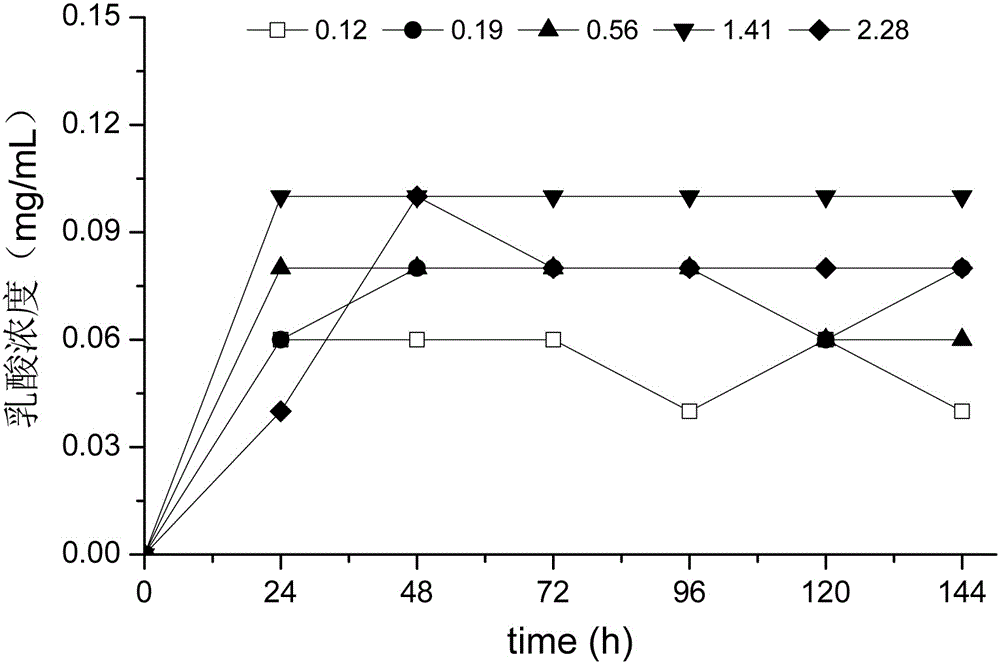

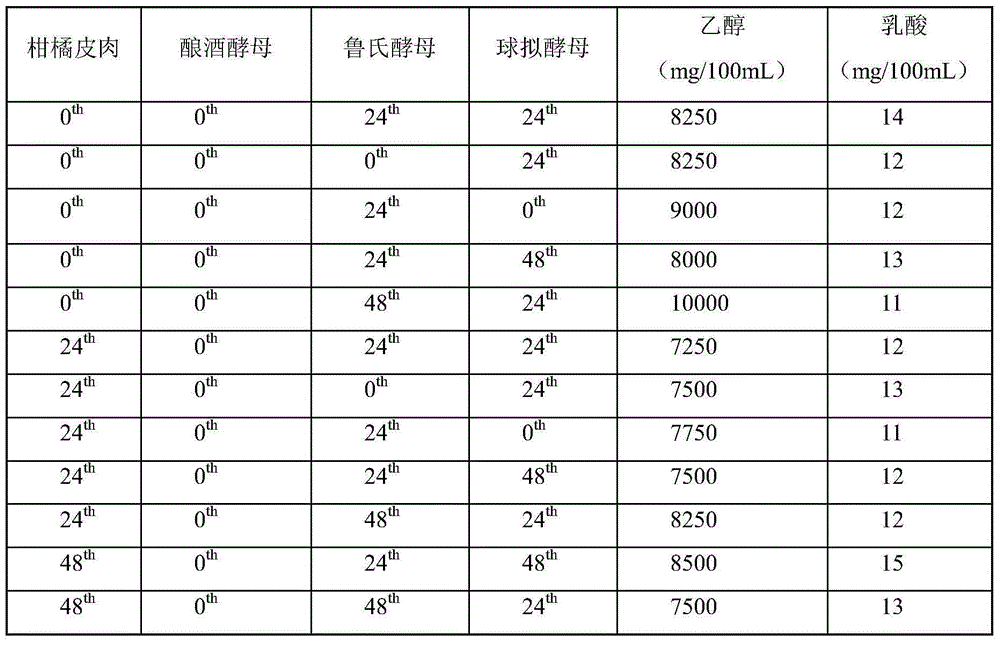

Citrus type brewed rice wine and preparation method thereof

The invention relates to the technical field of food fermentation engineering, in particular to citrus type brewed rice wine and a preparation method thereof. The citrus type brewed rice wine comprises, by weight, 1-3 parts of citrus peels, 8-14 parts of citrus flesh, 6-14 parts of glucose, 55-75 parts of sterile water, 1-5 parts of saccharomyces cerevisiae and 1-7 parts of flavor yeast. The flavor yeast is zygosaccharomyces rouxii or torulopsis utilis or comprises zygosaccharomyces rouxii and torulopsis utilis. The weight ratio of the citrus peels to the citrus flesh is 0.8-2.5:10. The citrus type brewed rice wine is prepared through the steps of citrus preparation, brewing substrate preparation, brewing and the like. The whole citrus is used as a main substrate, brewing is controlled, growth synergism and metabolism complementation of the various kinds of yeasts in the brewing process are utilized, and the flavor substance metabolism characteristics are brought into full play, so that the citrus utilization rate is high, the citrus flavor is remarkable, and the application range is wide.

Owner:HUBEI TULAOHAN FLAVORING FOOD

Thin-film type solar cell including by-pass diode and manufacturing method thereof

InactiveUS20090217966A1Enormous economic valueImprove photoelectric conversion efficiencyPV power plantsSemiconductor/solid-state device manufacturingMilitary FacilityElectricity

Owner:LG ELECTRONICS INC

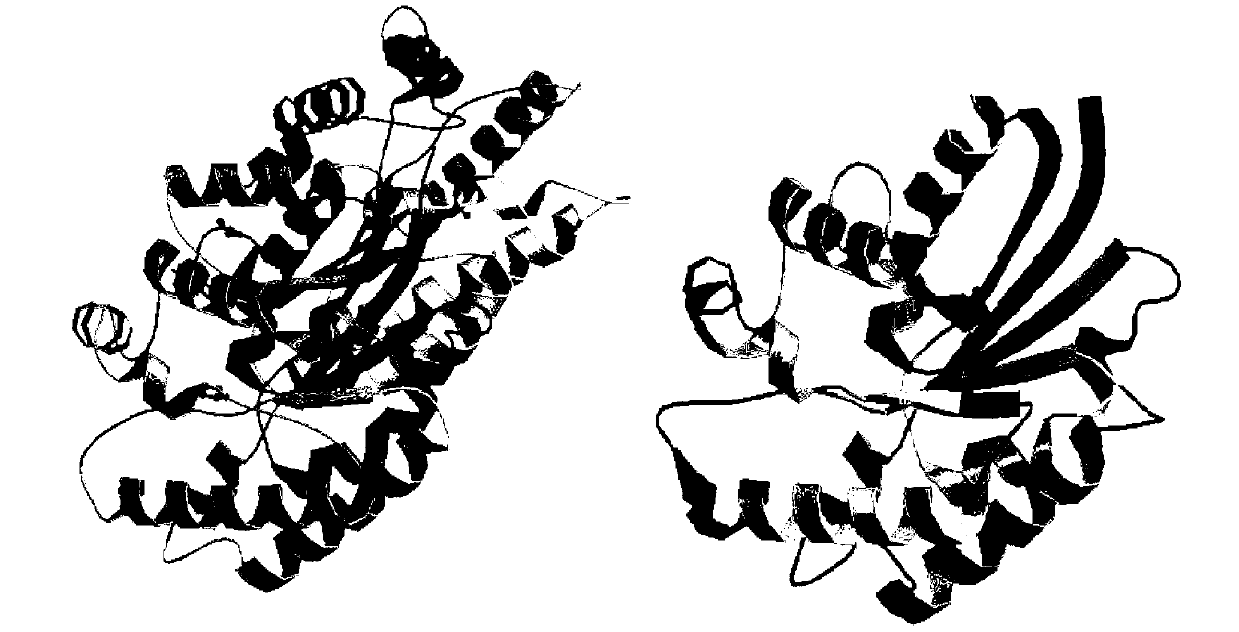

New application of GDSL protein to preparation of lipase

InactiveCN102876643AHas lipase activityIncrease enzyme activityBacteriaHydrolasesReaction temperatureThermal stability

The invention discloses new application of GDSL protein to preparation of lipase. The invention provides application of the GDSL protein to (1) preparation of lipases or (2) degradation of a substrate of the lipase. The GDSL protein is the following protein in (a) or (b): (a) the protein comprises the amino acid sequence shown as the sequence 2; and (b) the protein is formed in the way that the amino acid sequence shown as the sequence 2 is subjected to substitution and / or deletion and / or addition of one or more amino acid residues, has lipase activity and is derived from the sequence 2. The GDSL protein has lipase activity. The application of the GDSL protein as the lipase has the advantages of higher reaction temperature, high heat stability, action under the alkaline condition, high pH stability, effects on the substrates of C2-C12 and high enzyme activity. The invention opens up a new way for the process flow of the lipase and has a great economic value.

Owner:FEED RESEARCH INSTITUTE CHINESE ACADEMY OF AGRICULTURAL SCIENCES

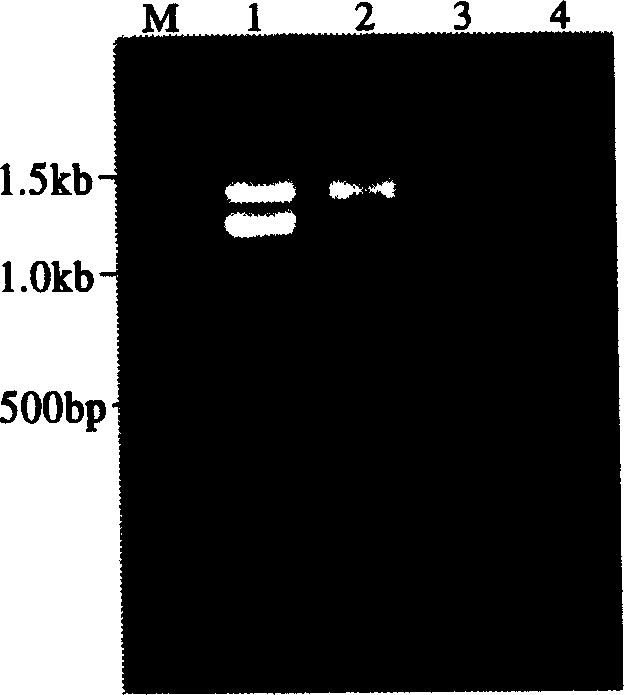

Antimicrobial peptide gene from pinctada fucata and application

ActiveCN101948839ASignificant economic valueAntibacterial agentsPeptide/protein ingredientsGenetic engineeringFungicide

The invention discloses cDNA of antimicrobial peptide gene AP from pinctada fucata, the nucleotide sequence is as shown in SEQ ID NO. 1, and the amino acid sequence can be deduced to be as shown in SEQ ID NO.2. The invention further discloses an expression vector containing the antimicrobial peptide gene from the pinctada fucata and a recombinant microbe transformed by utilizing the vector, discloses a method for preparing the antimicrobial peptide gene from the pinctada fucata by utilizing the microbe, and simultaneously discloses an application of the antimicrobial peptide gene from the pinctada fucata in the preparation of drugs for treating or preventing sea water pearl oyster type anti-gram-negative bacteria. The invention adopts the genetic engineering technology for producing recombinant antimicrobial peptide protein from the pinctada fucata, and the recombinant antimicrobial peptide protein is utilized for preparing sea water pearl oyster antibacterial agents or fungicides.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

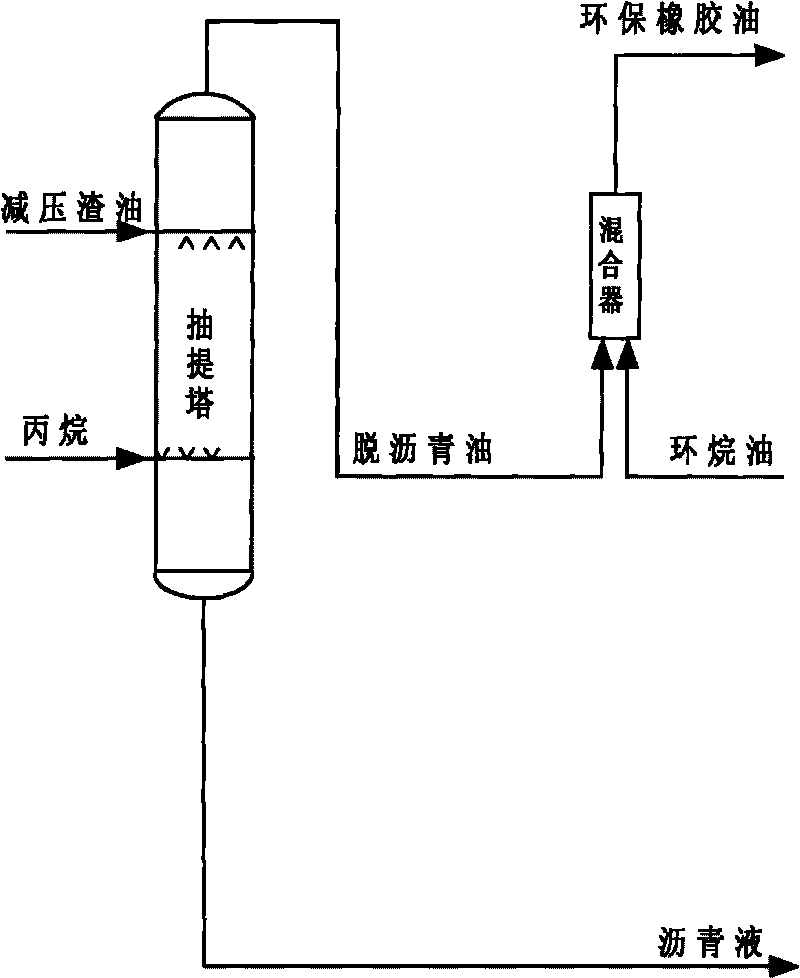

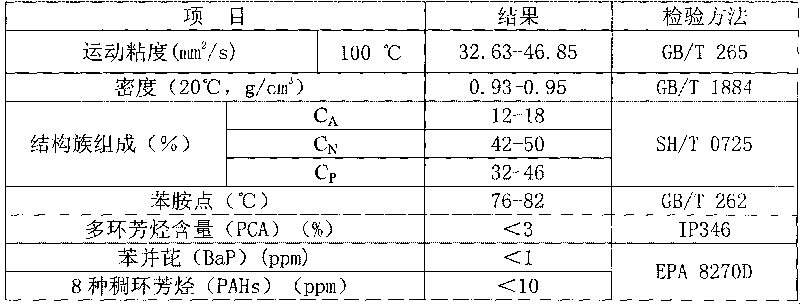

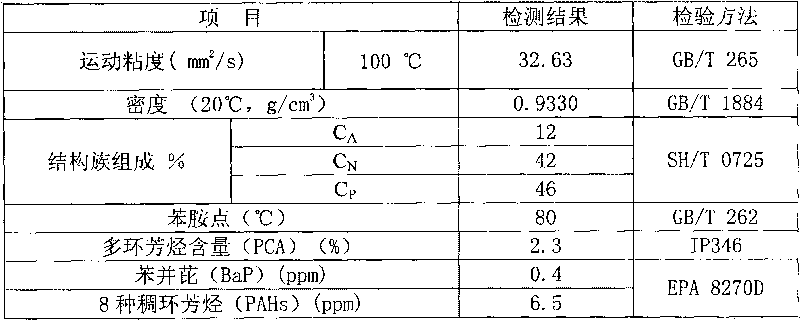

Method for producing environment-friendly rubber oil through blending method

ActiveCN101693772AImprove wet skid resistanceHigh aromatic contentHydrocarbon oils refiningResidual oilTower

The invention discloses a method for producing environment-friendly rubber oil through blending method. The method provided by the invention comprises the following steps that firstly extracting decompressed residual oil with solvent to obtain deasphalted oil, wherein the solvent for extraction is propane, the ratio by volume of the solvent and the decompressed residual oil is (6-8):1, and the extraction conditions are that the temperature of a tower top is 60-95 DEG C, the temperature of a tower bottom is 50-80 DEG C, and the pressure is 2.8-7.0 MPa, secondly mixing deasphalted oil obtained in the first step with naphthenic oil for 30-120 min with 70-90 DEG C to obtain environment-friendly rubber oil, wherein the mass ratio of the deasphalted oil and the naphthenic oil is (0.2-0.6):(0.8-0.4). The environment-friendly rubber oil produced by the invention accords with the environment-friendly instruction requirement of EU 2005 / 69 / EC, wherein aromatic-carbon rate is 12%-18%, the content of PCA is smaller than 3%, the content of aromatic hydrocarbons is high, and the rubber oil is environment-friendly, nontoxic, and has no carcinogenic effect. The environment-friendly rubber oil can be used as succedaneum of existing aromatic oil, and has great economic values.

Owner:CHINA NAT OFFSHORE OIL CORP +2

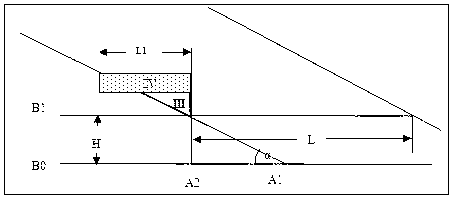

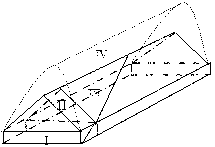

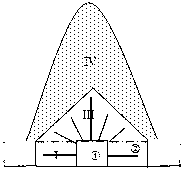

Method for improving ore recovery rate of gentle dip ore body by non-pillar sublevel caving

InactiveCN103104258AImprove recycling effectAlleviate the strain on resourcesUnderground miningSurface miningMining engineeringMechanical engineering

The invention discloses a method for improving ore recovery rate of a gentle dip ore body by non-pillar sublevel caving. The method is realized by secondary recovery of a triangular ore cone in a lower disc of the sublevel ore body as well as ore residues at the ridge of the upper part by means of paving assistant recovery accesses in a peach-shaped jamb between two accesses, wherein the specification of the assistant recovery accesses is smaller than dimension of a normal mining roadway and is 2.0*2.0m to 3.0*3.0m. According to the method, the ore recovery rate by the integral mining method is improved by about 5%, maximally about 8-10%; and the quantity of ore recovered in an accumulated manner and the waste ore mixing amount reduced are great, and the benefit is very remarkable.

Owner:SOUTHWEAT UNIV OF SCI & TECH

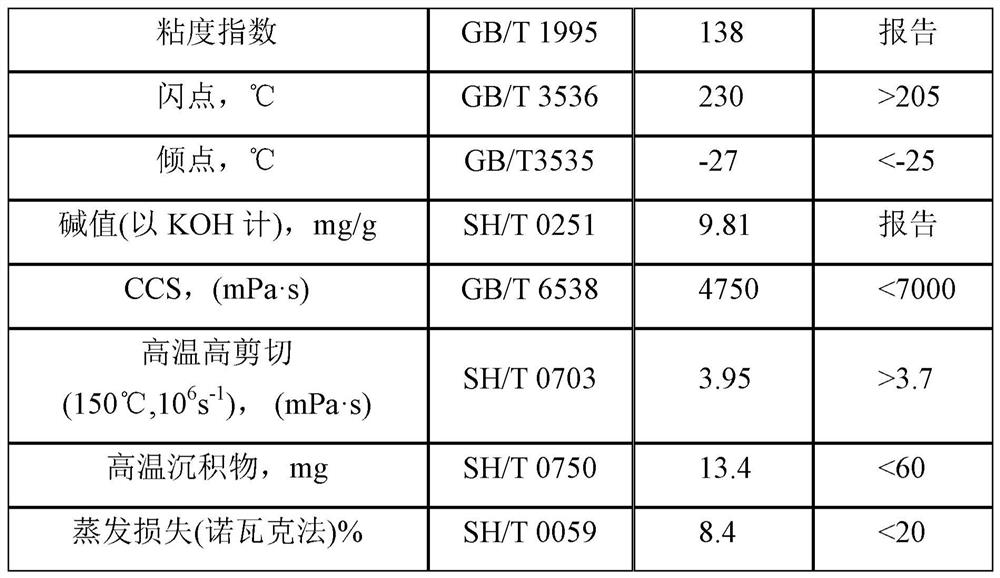

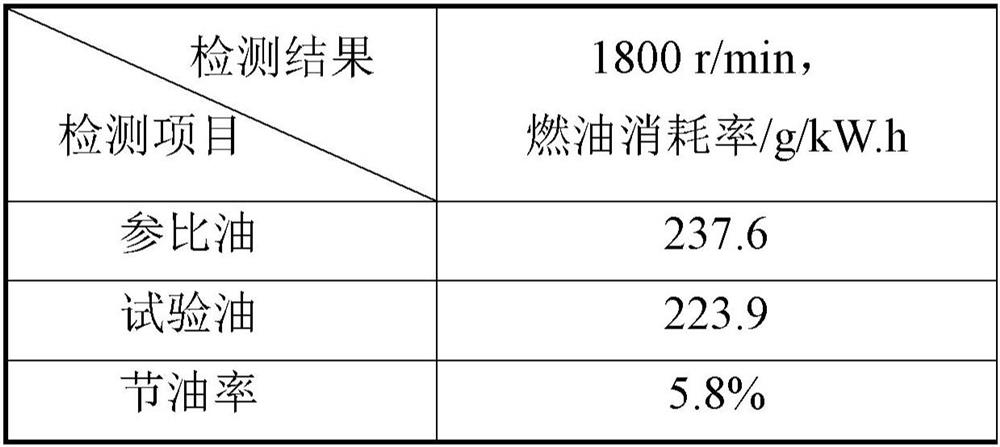

Diesel engine oil and preparation method thereof

InactiveCN111849594AImprove fuel saving effectImprove antioxidant capacityLubricant compositionFoaming agentDieseling

The invention relates to diesel engine oil and a preparation method thereof, and the diesel engine oil comprises the following components in percentage by mass: 2-4% of a detergent; 2-3% of a dispersant; 0.5 to 2% of an antioxidant; 6-11% of a viscosity index improver; 0.1 to 0.4% of a pour point depressant; 0.1 to 0.5% of a friction modifier; 0.001 to 0.005% of an anti-foaming agent; and the balance of base oil. The diesel engine oil provided by the invention has good oil-saving capacity, and the oil-saving rate is 5.8% or above; the diesel engine oil provided by the invention has better oxidation resistance, better wear resistance and better energy-saving effect, and has great practicability, feasibility and great economic value.

Owner:天津内燃机研究所(天津摩托车技术中心)

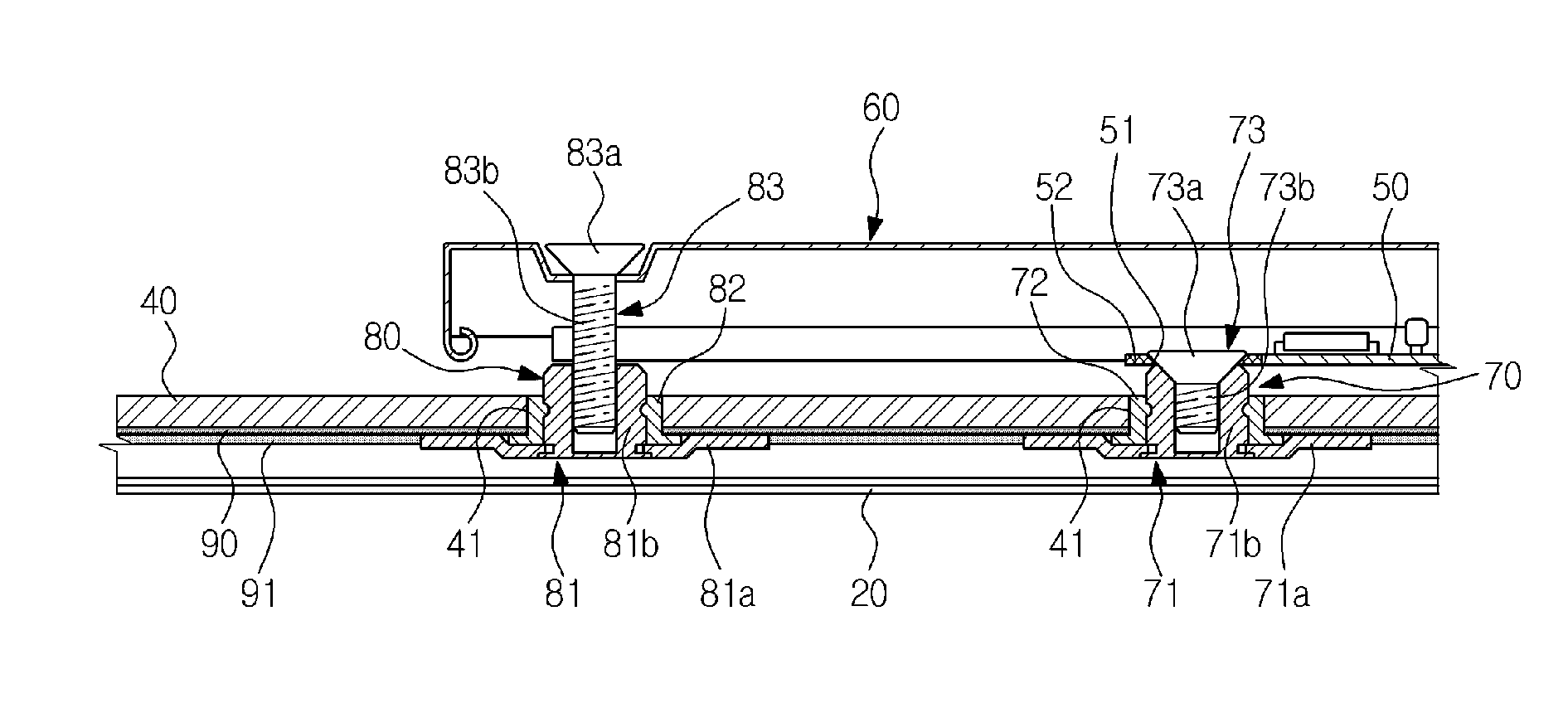

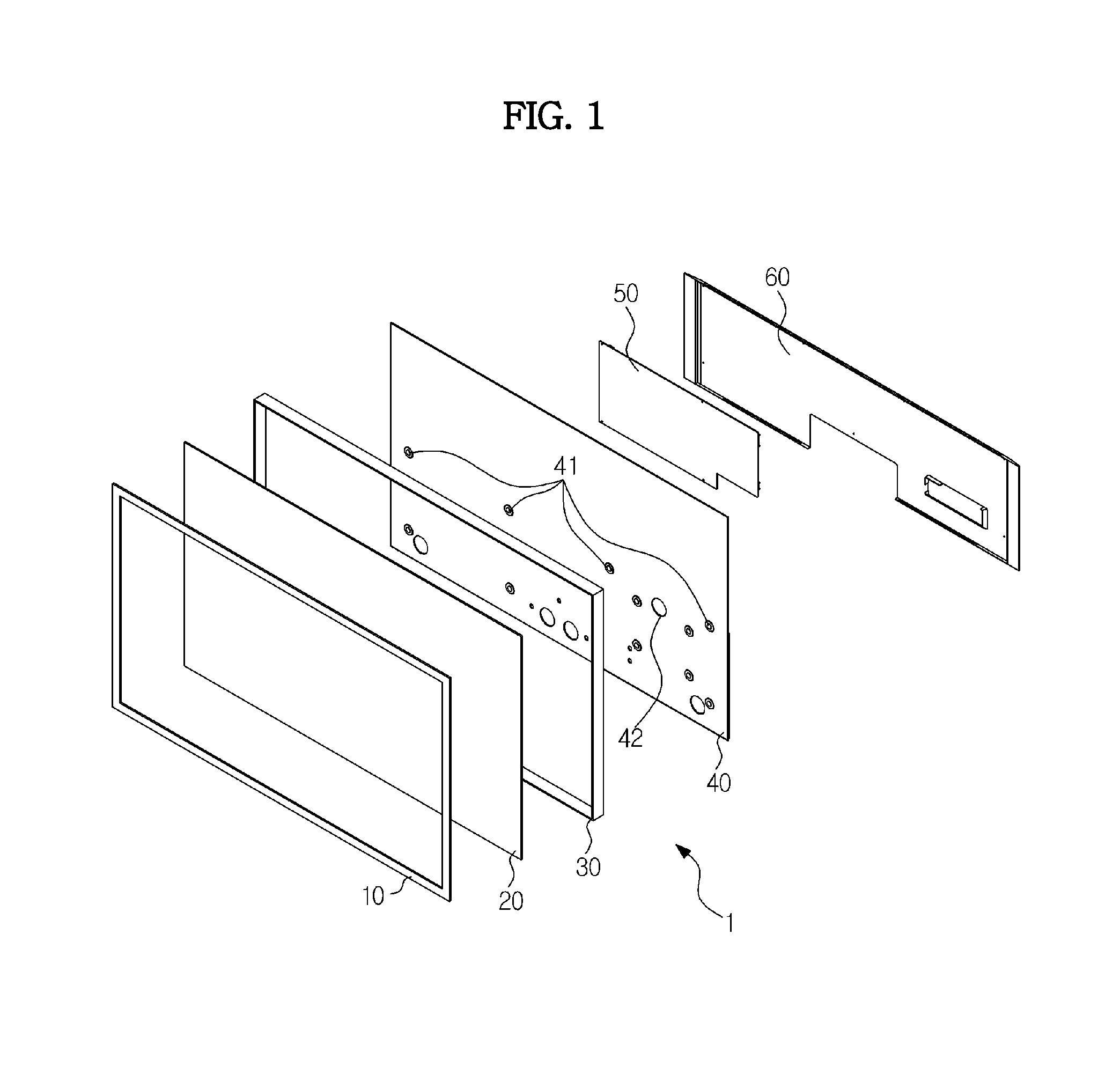

Display apparatus with an electromagnetic wave shielding structure

InactiveUS20130163214A1Avoid distractionSignificant economic valueLocalised screeningNon-linear opticsElectricityReducer

A display apparatus having an electromagnetic wave shielding structure and an electromagnetic wave reducing structure, are provided. The electromagnetic wave shielding and reducing structures are applicable to various materials. The display apparatus includes a display panel, a rear case disposed at a rear of the display panel and formed of a non-conductive material, a printed circuit board disposed at a rear of the rear case, and an electromagnetic wave reducer provided at one surface of the rear case and being formed of a conductive material to reduce the electromagnetic wave generated at the printed circuit board, wherein the electromagnetic wave reducer is electrically connected to the printed circuit board.

Owner:SAMSUNG ELECTRONICS CO LTD

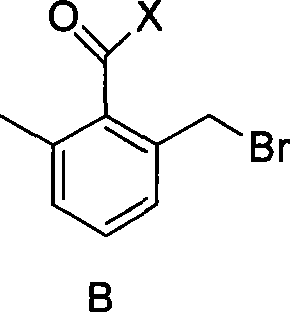

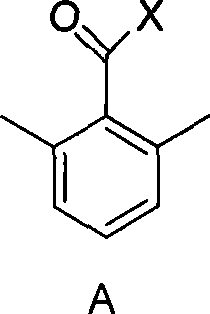

2-bromomethyl-6-methyl benzoyl chloride/bromium and preparation method thereof

ActiveCN101381302AEasy to operateMild reaction conditionsOrganic compound preparationCarboxylic compound preparationOrganic solventBromine

The invention discloses a compound of 2-bromomethyl-6-methyl benzoylformylchloride / bromide as shown in a formula B and a preparation method thereof. The preparation method is as follows: in the presence of a catalyst of bromization reaction, a compound of 2,6-dimethylbenzoyl chloride / bromide as shown in a formula A reacts with a bromide reagent in an inert organic solvent, wherein X is Cl or Br. The method of the invention has the advantages of higher product yield and purity, simple operation, mild reaction conditions and high selection of the bromization reaction; and is not only suitable for small-scale preparation in a laboratory, but also for industrial mass production.

Owner:CHINA GATEWAY PHARMA DEV CO LTD

Inorganic adhesive agent, preparation and application thereof

InactiveCN101319126AImprove bonding efficiencyImprove resource utilizationSolid waste managementInorganic adhesivesAdhesiveHydroxide

The invention provides an inorganic adhesive and a preparation method and an application thereof. The inorganic adhesive is characterized in that the adhesive comprises a first group of material and a second group of material, wherein the first group of material comprises one or more than one oxide or hydroxide; and the second group of material comprises one or more than one phosphorus-containing acid or salt. The inorganic adhesive can play an important role in emission treatment and resource regeneration; for example, a high-grade efficient covering proposal, etc. is provided for the reuse of harmless wastes and the treatment of harmful wastes.

Owner:BEIJING SAILIGE TECH DEV CORP

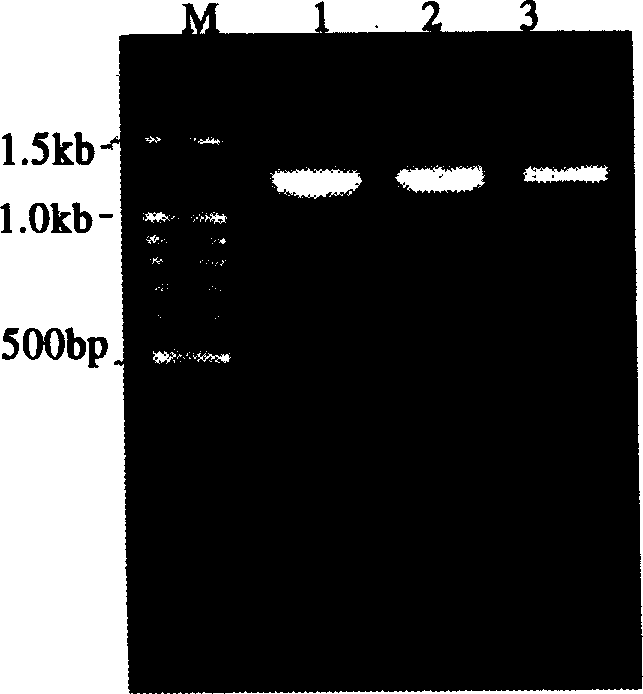

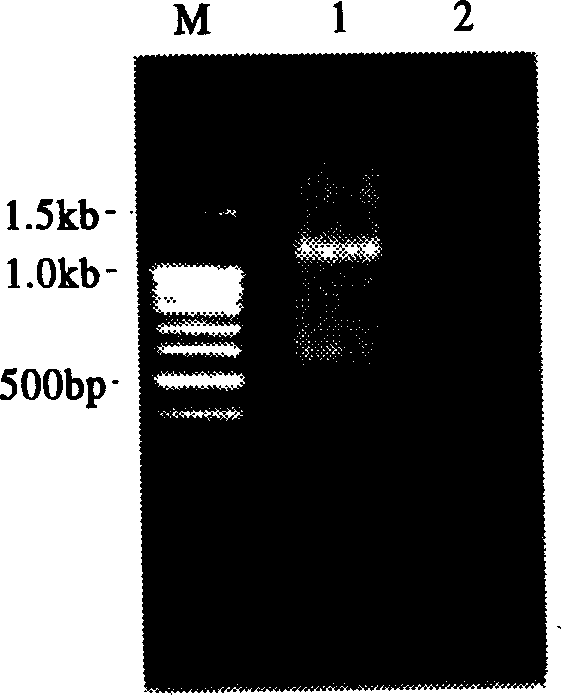

Rockfish insulin like growth factor I receptor gene and its application

InactiveCN1597954ASignificant economic valuePromote growthInsulin-like growth factorsGenetic engineeringInsulin-like growth factorTotal rna

The invention discloses a rockfish insulin-like growth factor I receptor gene, which is a gene fragment with rockfish insulin-like growth factor I receptor gene cDNA sequence, obtained by using rockfish hypothalamic total RNA as a template and by RT-PCR and Gene RACER methods. The invention can obtain stable-source and low-cost recombinant protein of rockfish insulin-like growth factor I receptor, having an important application to preparing fry growth promoter or additive.

Owner:SUN YAT SEN UNIV

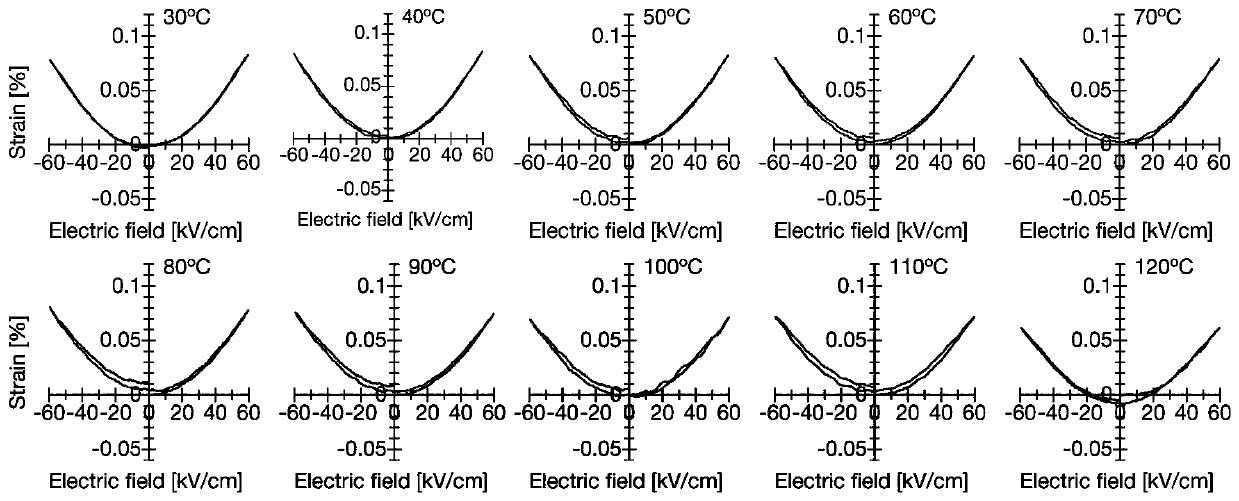

Sodium bismuth titanate-based lead-containing ferroelectric ceramic material with wide temperature stabilized electrostrictive strain, preparation method and applications thereof

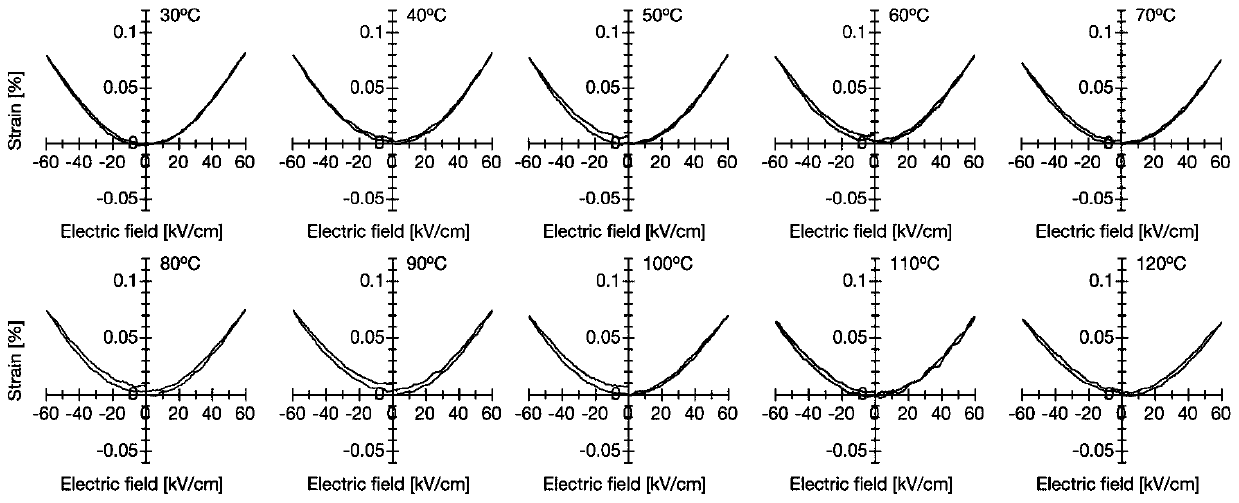

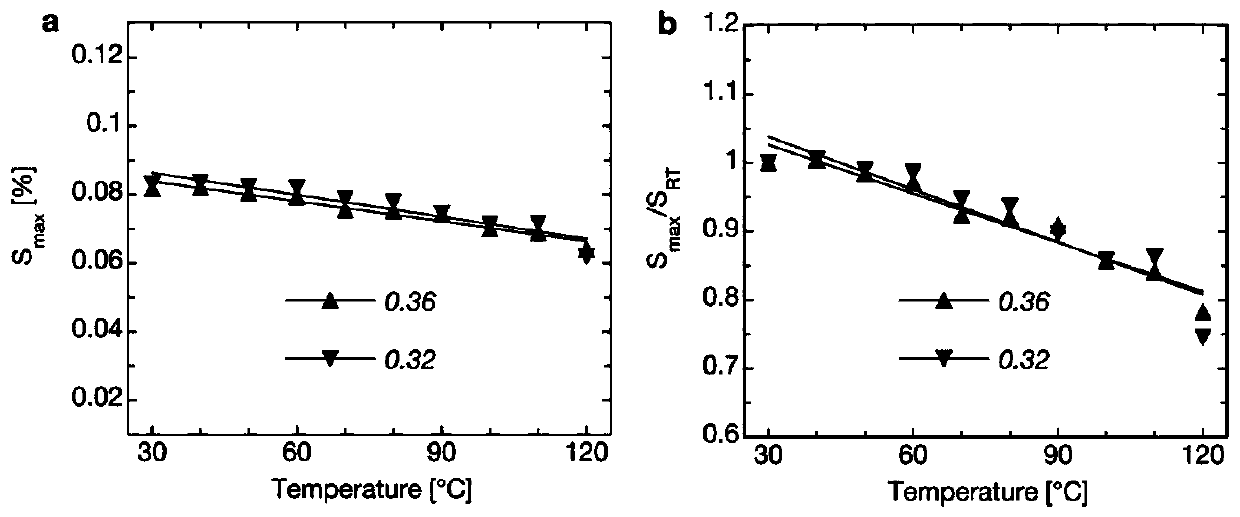

The invention discloses a sodium bismuth titanate-based lead-containing ferroelectric ceramic material with wide temperature stabilized electrostrictive strain, a preparation method and applications thereof, and belongs to the technical field of electronic ceramic materials, wherein the chemical composition of the ceramic material is (1-x)Bi1 / 2Na1 / 2TiO3-xPbMg1 / 3Nb2 / 3O3, and x is 0.32-0.36. According to the present invention, the material system can be synthesized at a low temperature by using a solid phase reaction method to obtain electrostrictive strain with high density and wide temperaturestability; at a temperature of 30-120 DEG C, under the action of an electric field of 60 kV / cm, the maximum value of the low-hysteresis electrostrictive strain is 0.06-0.08%, and the change rate is less than 30%; the method has characteristics of simple components, simple process steps, easy operation and good repeatability; and the product can be used in high precision drivers with high temperature stability requirements, and has great economic value.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com