Diesel engine oil and preparation method thereof

A diesel engine and base oil technology, applied in the field of diesel engine oil and its preparation, can solve problems such as lubricating effect reduction, cylinder wear, acceleration equipment, etc., and achieve good anti-oxidation performance, good energy-saving effect, and great practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention also discloses a preparation method of diesel engine oil, comprising:

[0039] Mix the components of the above diesel engine oil except the base oil, add them into the base oil at a certain temperature, and stir to obtain the diesel engine oil.

[0040] In some embodiments of the present invention, the stirring time is 1 to 3h;

[0041] In some embodiments of the present invention, the stirring method includes mechanical stirring or pulse stirring;

[0042] In some embodiments of the present invention, the certain temperature is 55 to 65°C.

[0043] In an exemplary embodiment, the technical scheme adopted in the present invention is as follows: a formula of engine oil, gasoline and engine oil, each component is calculated by weight percentage, and includes the following components:

[0044] 1) Detergent 2-4%: The detergent used is one or a combination of two or more of synthetic calcium sulfonate, sulfurized alkylphenate calcium, and alkyl salicylate cal...

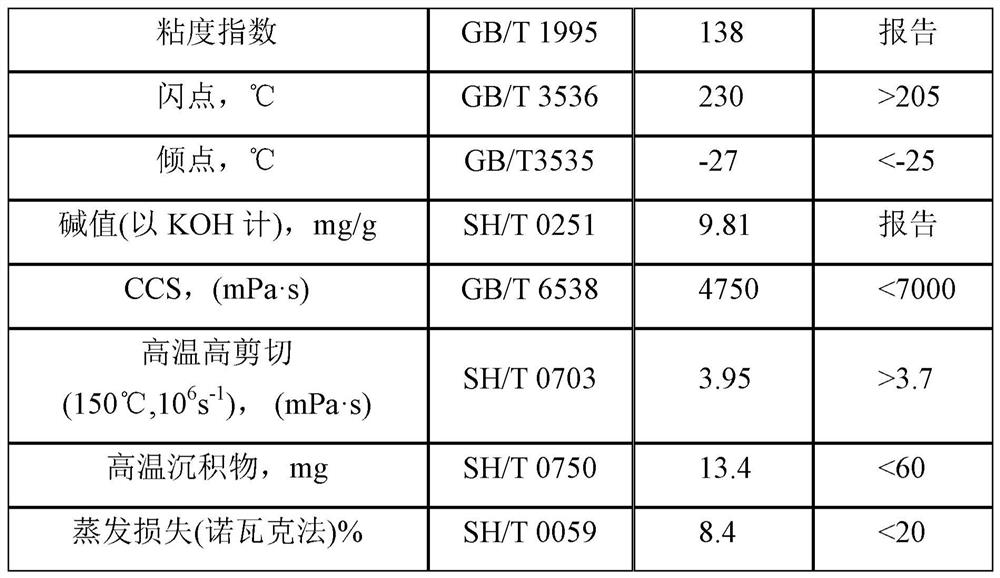

Embodiment 1

[0057] In this embodiment, the components of the diesel engine oil are blended according to the mass fraction ratio, and the viscosity grade is 15W-40, specifically:

[0058] Group II base oil: viscosity is 150N, content is 41.4%;

[0059]Group II base oil: viscosity is 600N, content is 36%;

[0060] Group I base oil: viscosity is 150BS, content is 5.5%;

[0061] Viscosity index improver: ethylene propylene rubber type, the content is 9%;

[0062] Detergent 1: calcium salicylate with a high alkali value (alkali value greater than 265 mgKOH / g), with a content of 1.6%;

[0063] Detergent 2: calcium sulfonate with high alkali value (alkali value greater than 295mgKOH / g), the content is 0.5%;

[0064] Detergent 3: Calcium salicylate with medium alkali value (alkali value greater than 145mgKOH / g), with a content of 1.2%;

[0065] Dispersant 1: Polymer ashless dispersant with a content of 2.8%;

[0066] Antioxidant 1: zinc dialkyl dithiophosphate, content is 1%;

[0067] Antio...

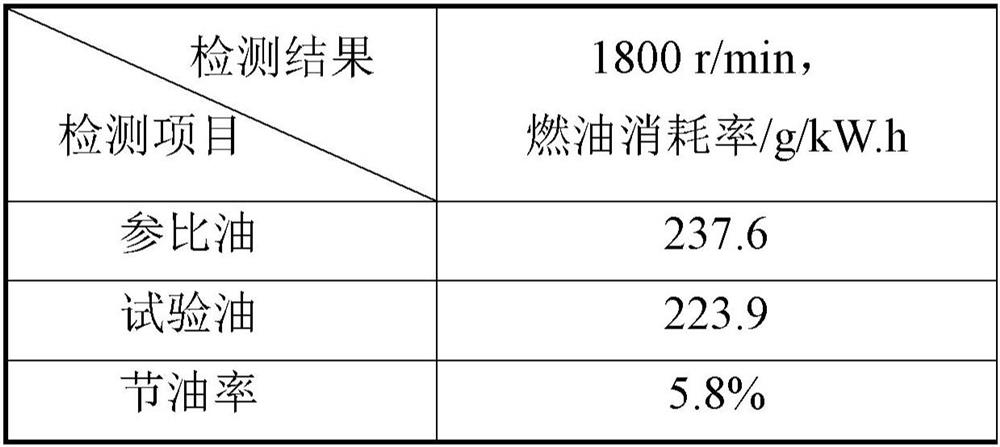

Embodiment 2

[0073] In this embodiment, the components of the diesel engine oil are blended according to the mass fraction ratio, and the viscosity grade is 10W-30, specifically:

[0074] Group II base oil: viscosity is 150N, content is 39.7%;

[0075] Group II base oil: viscosity is 500N, content is 15%;

[0076] Group III base oil: viscosity is 100N, content is 30%;

[0077] Viscosity index improver: polyhydrogenated styrene isoprene type, the content is 7%;

[0078] Detergent 1: high alkali value calcium sulfonate (alkali value greater than 295mgKOH / g), the content is 2%;

[0079] Detergent 2: medium alkali value sulfurized alkylphenate calcium (alkali value greater than 145mgKOH / g), the content is 1.4%;

[0080] Dispersant 1: boronated succinimide, the content is 2.5%;

[0081] Antioxidant 1: zinc dialkyldithiophosphate, the content is 1.2%;

[0082] Antioxidant 2: alkyl diphenylamine, the content is 0.5%;

[0083] Friction modifier: modified nano-lanthanum fluoride particles, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com