Sodium bismuth titanate-based lead-containing ferroelectric ceramic material with wide temperature stabilized electrostrictive strain, preparation method and applications thereof

A sodium bismuth titanate-based, electro-straining technology is applied in the field of electronic ceramic materials, which can solve the problems of electric field-induced polarization drop, limiting the strain performance of sodium bismuth titanate-based ferroelectric ceramics, and disruption, and achieves good repeatability. , easy to operate, the effect of great economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

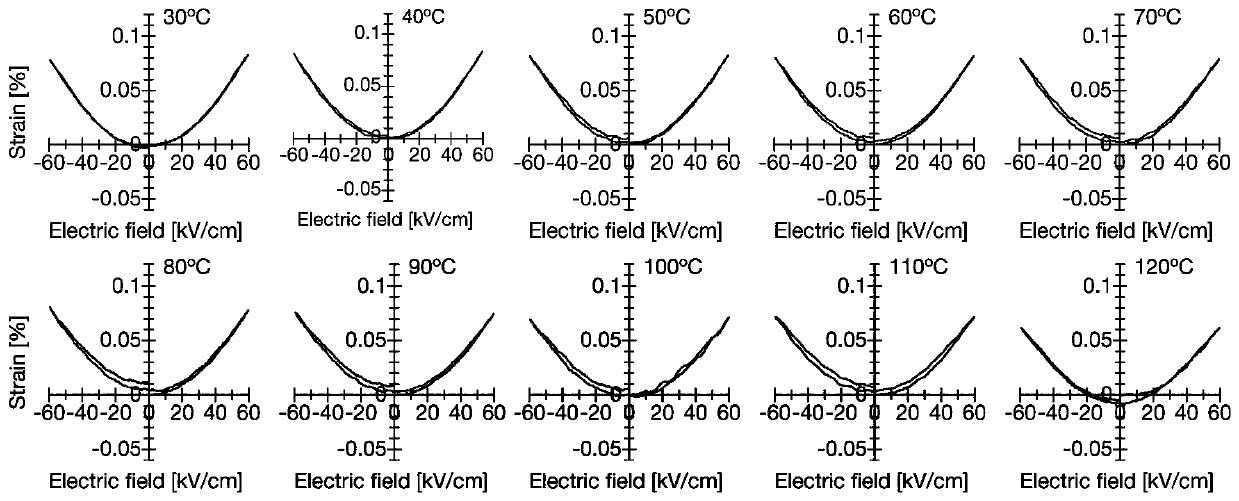

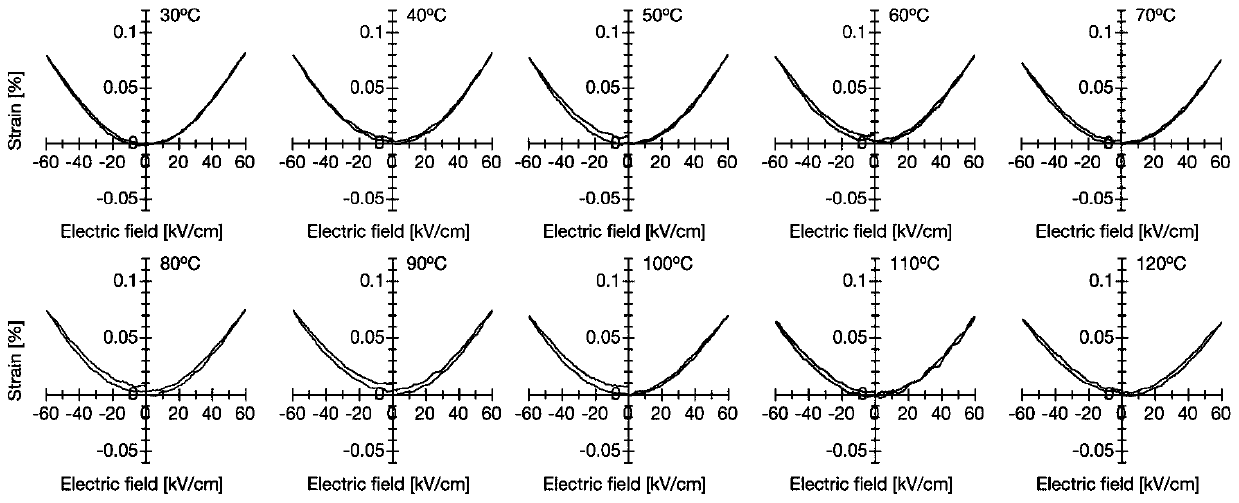

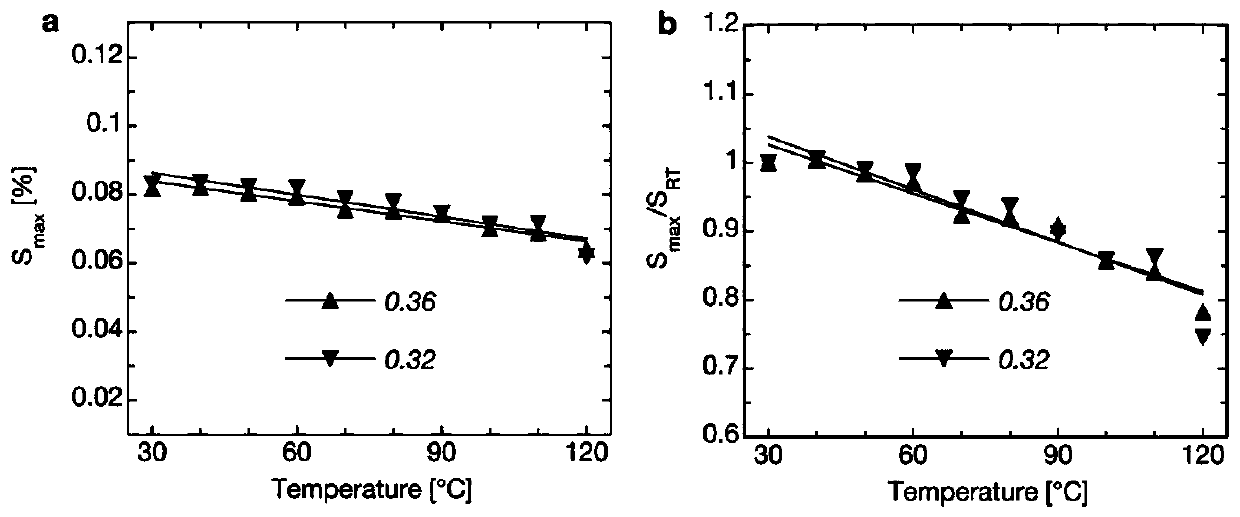

[0027] A bismuth sodium titanate ferroelectric ceramic material with stable electric strain over a wide temperature range has the following chemical composition:

[0028] 0.68Bi 1 / 2 Na 1 / 2 TiO 3 -0.32PbMg 1 / 3 Nb 2 / 3 o 3 , abbreviated as BNT-0.32PMN, the sintering temperature is 1150°C, recorded as sample 1, marked as #1.

[0029] Sample 1 was prepared as follows:

[0030] 1) According to the chemical expression 0.68Bi 1 / 2 Na 1 / 2 TiO 3 -0.32PbMg 1 / 3 Nb 2 / 3 o 3 Weigh Bi 2 o 3 , Na 2 CO 3 ,TiO 2 , PbO and MgNb 2 o 6 . Mix the weighed raw materials and put them into a ball mill jar, add the ball milling solvent isopropanol and zirconia balls, mill for 12 hours, and the ball milling speed is 250 rpm, then put the mixture in an oven for drying at 80°C, put Grind in a mortar and pass through an 80-mesh sieve; pre-fire in a muffle furnace at 800 ° C for 2 hours, cool to room temperature naturally, and take out the furnace; ball mill again to synthesize BNT-xPMN.

...

Embodiment 2

[0036] A bismuth sodium titanate ferroelectric ceramic material with stable electric strain over a wide temperature range has the following chemical composition:

[0037] 0.64 Bi 1 / 2 Na 1 / 2 TiO 3 -0.36PbMg 1 / 3 Nb 2 / 3 o 3 , abbreviated as BNT-0.36SBT, the sintering temperature is 1150°C, recorded as sample 2, marked as #2.

[0038] Sample 2 was prepared as follows:

[0039] 1) According to the chemical expression 0.64Bi 1 / 2 Na 1 / 2 TiO 3 -0.36PbMg 1 / 3 Nb 2 / 3 o 3 Weigh Bi 2 o 3 , Na 2 CO 3 ,TiO 2 , PbO and MgNb 2 o 6 . Mix the weighed raw materials and put them into a ball mill jar, add the ball milling solvent isopropanol and zirconia balls, mill for 12 hours, and the ball milling speed is 250 rpm, then put the mixture in an oven for drying at 80°C, put Grind in a mortar and pass through an 80-mesh sieve; pre-fire in a muffle furnace at 800 ° C for 2 hours, cool to room temperature naturally, and take out the furnace; ball mill again to synthesize BNT-xPMN.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com