Method for improving ore recovery rate of gentle dip ore body by non-pillar sublevel caving

A segmented caving method without pillars, which is applied in ground mining, earth square drilling, underground mining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

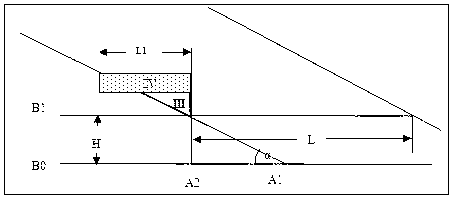

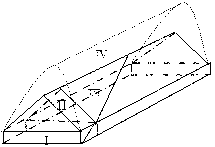

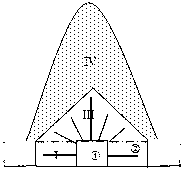

[0011] In order to ensure a good recovery effect and safety in the mine, the normal recovery roadway is ahead of the auxiliary recovery roadway in the mining sequence. When the normal recovery roadway on both sides is finished and the ground pressure is fully released, the auxiliary mining roadway will be excavated and recovered. The auxiliary roadway is still mined row by row by vertical upward fan-shaped hole blasting, and so on until the mining of the residual ore at the triangular ore cone and its ridge is completed.

[0012] If the lower section corresponding to the stud has withdrawn to the design boundary, the auxiliary recovery approach only needs to be excavated to the caving area at this level, and there is no need to excavate the cutting groove. However, if the lower section has not retreated to the designed footwall boundary, the secondary recovery roadway can only be excavated to the distance of 1-2 rows of holes in the ore body direction of the footwall ore-rock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com