TFT-LCD (Thin Film Transistor Liquid Crystal Display) array substrate and manufacture method thereof

An array substrate and substrate technology, applied in the thin film transistor liquid crystal display structure and its manufacturing field, can solve problems such as aggravating afterimage, achieve the effects of delaying afterimage, reducing the influence of photoelectric performance, and avoiding leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

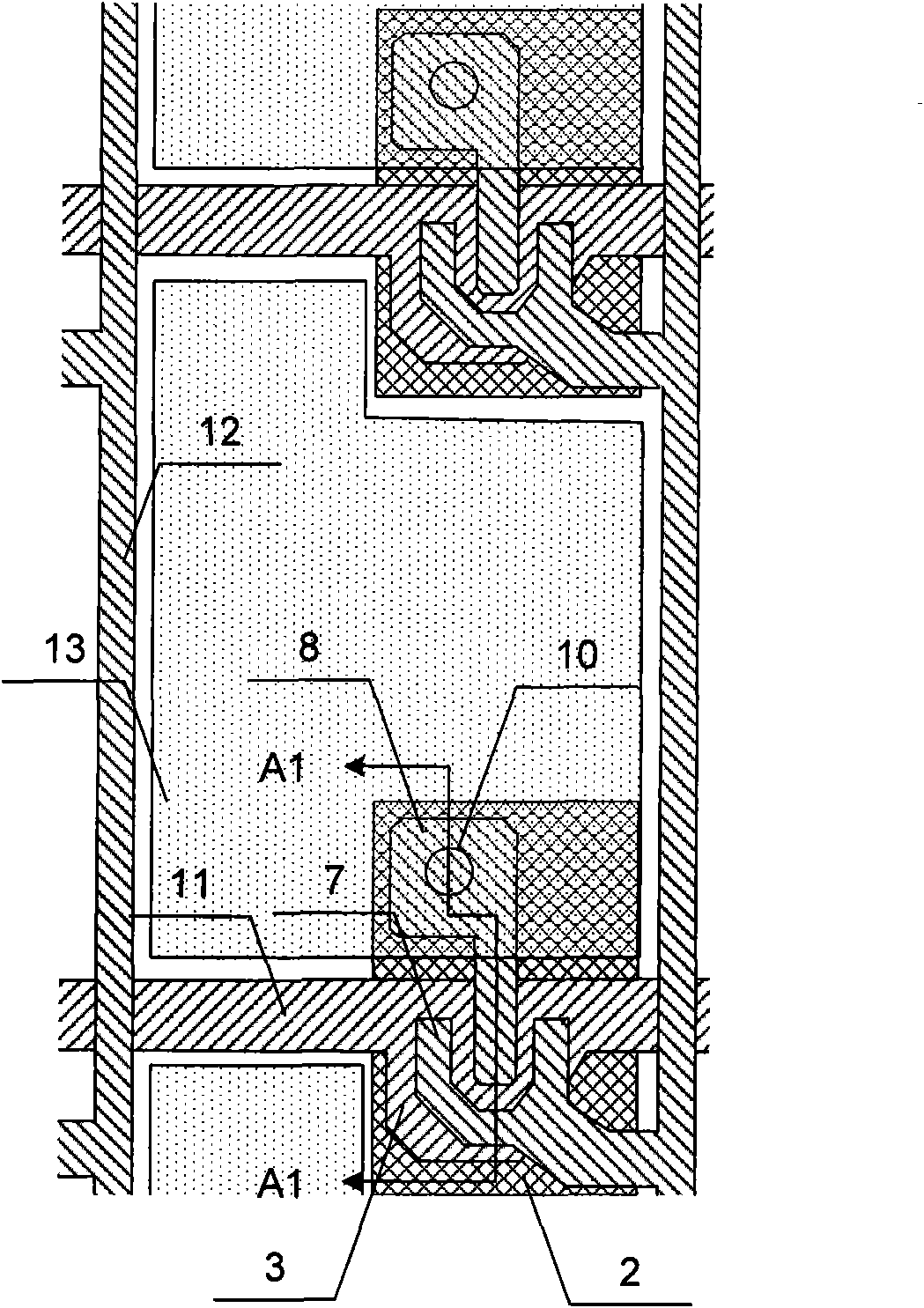

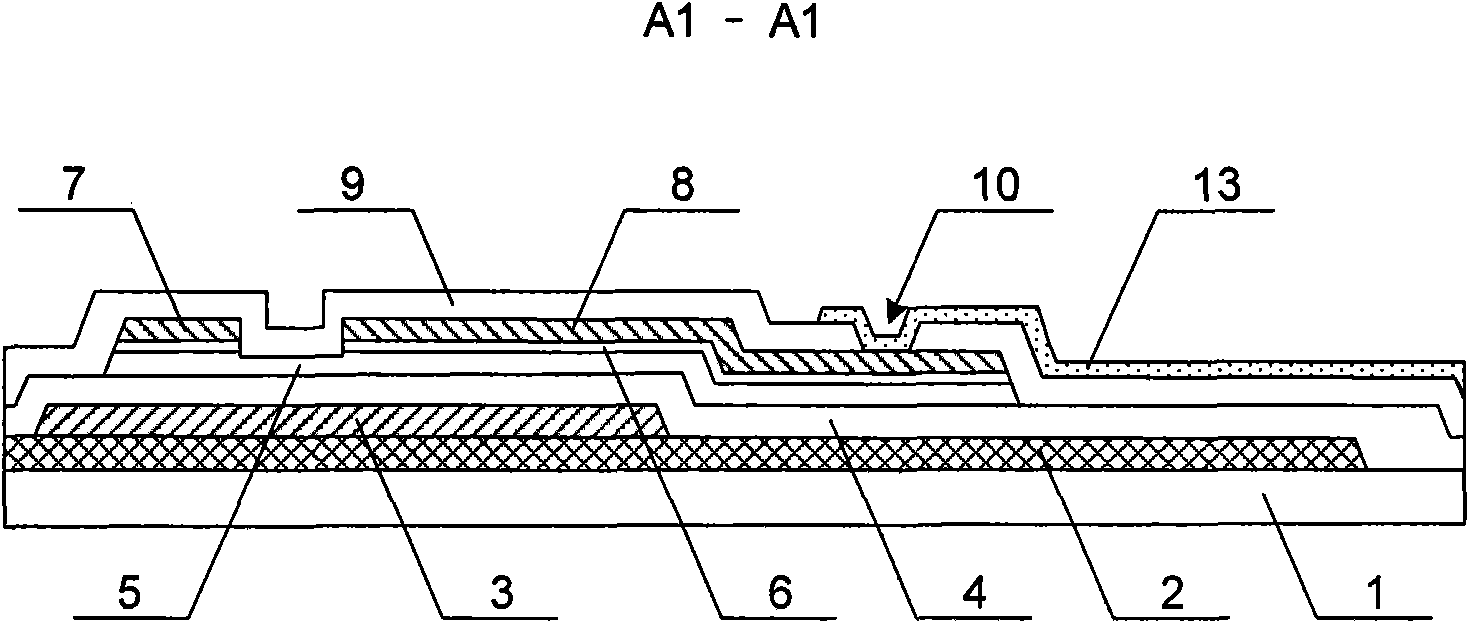

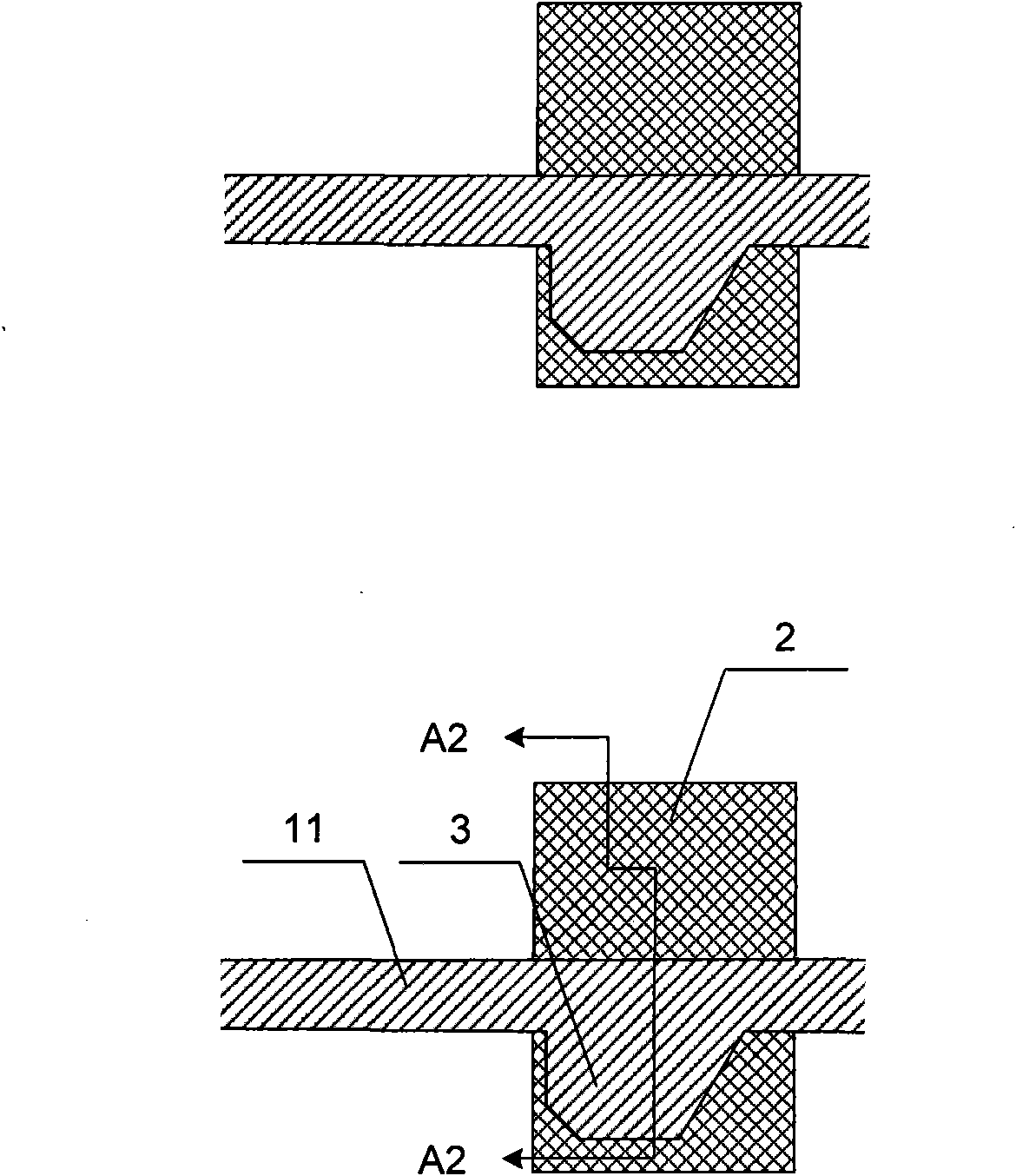

[0072] figure 1 It is a plan view of the TFT-LCD array substrate of the present invention, reflecting the structure of a pixel unit, figure 2 for figure 1 Sectional view of A1-A1 in the middle. Such as figure 1 and figure 2 As shown, the main structure of the TFT-LCD array substrate of the present invention includes gate lines 11, data lines 12, pixel electrodes 13, thin film transistors and light-shielding patterns 2 formed on the substrate 1, and the mutually perpendicular gate lines 11 and data lines 12 define A pixel area is formed, a thin film transistor and a pixel electrode 13 are formed in the pixel area, the gate line 11 is used to provide a turn-on signal to the thin film transistor, the data line 12 is used to provide a data signal to the pixel electrode 13, and the light-shielding pattern 2 is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com