PNPNP type triac

An N-type, substrate technology, applied in the direction of electrical components, thyristors, diodes, etc., can solve problems such as ESD protection that is difficult to apply to mixed voltage interface circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

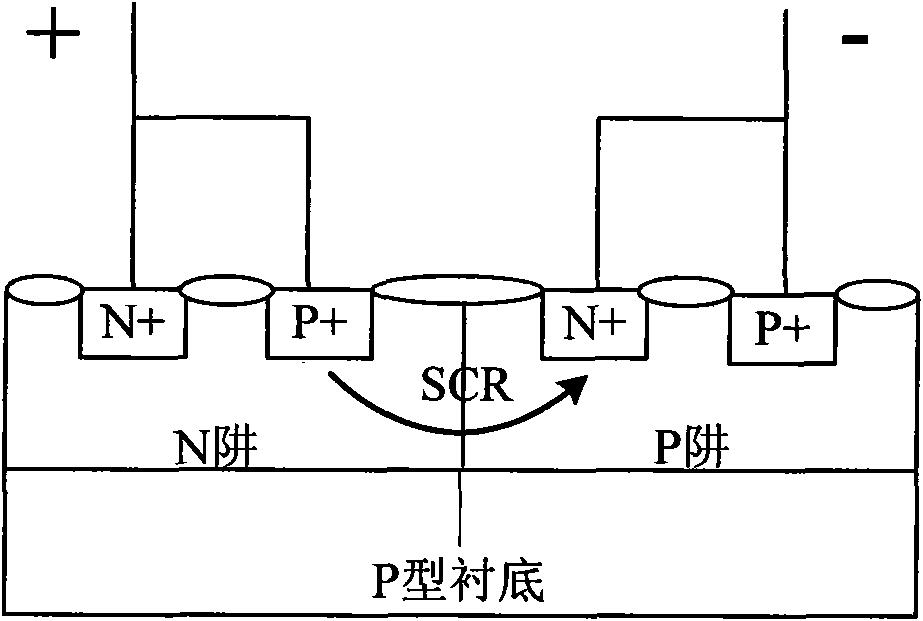

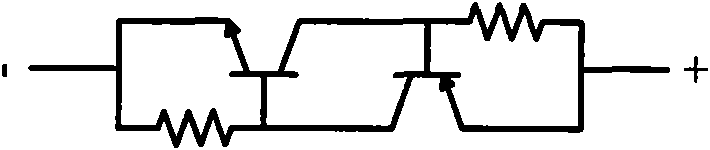

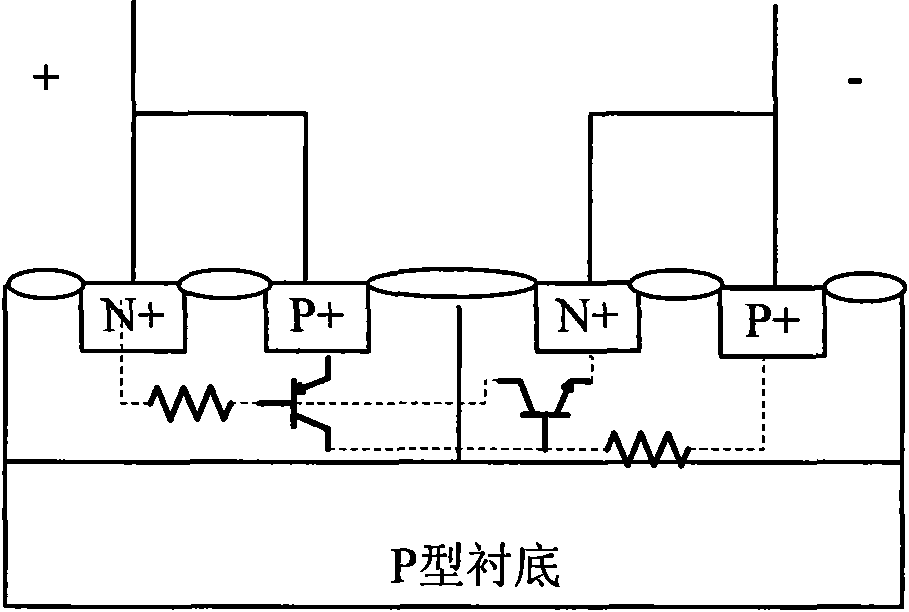

[0020] Such as Figure 5 As shown, a PNPNP-type bidirectional thyristor includes a P-type substrate 50, the P-type substrate 50 is an open type, and an N-type buried layer 51 is arranged on the bottom surface of the opening, and a P-well 53 is injected on the N-type buried layer. An annular N-well 52 is provided between the side of the P-well 53 and the P-type substrate. The junction depths of the N-well 52 and the P-well 53 are the same, and the P-well 53 is completely isolated from the P-type substrate 50 .

[0021] A symmetrical N-type drift region 54a and an N-type drift region 54b are injected into the P well, a P+ implantation region 56 and an N+ implantation region 55 are injected into the N-type drift region 54a, and a P+ implantation region 57 and a P+ implantation region 57 are injected into the N-type drift region 54b. The N+ implantation region 58, wherein the P+ implantation region 57 and the P+ implantation region 56 are located inside, and the P-type substrate 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com