Polyester resin solution for production of thermally cured film

A polyester resin, thermal curing technology, used in polyester coatings, coatings, instruments, etc., can solve the problems of low solubility, difficult to apply to flattening film production lines, flattening and transparency reduction, etc., to achieve high flatness Chemical resistance, high solvent resistance, high transparency effect

Inactive Publication Date: 2010-08-18

NISSAN CHEM IND LTD

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in the case of a flattening film used as a color filter, there are problems such as a significant decrease in flattening properties and transparency.

In addition, although polyimide or polyamic acid is soluble in solvents such as N-methylpyrrolidone or γ-butyrolactone, it has low solubility in glycol solvents or ester solvents, so it is difficult to apply to flat surfaces. Chemical film production line

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

Embodiment

Synthetic example 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

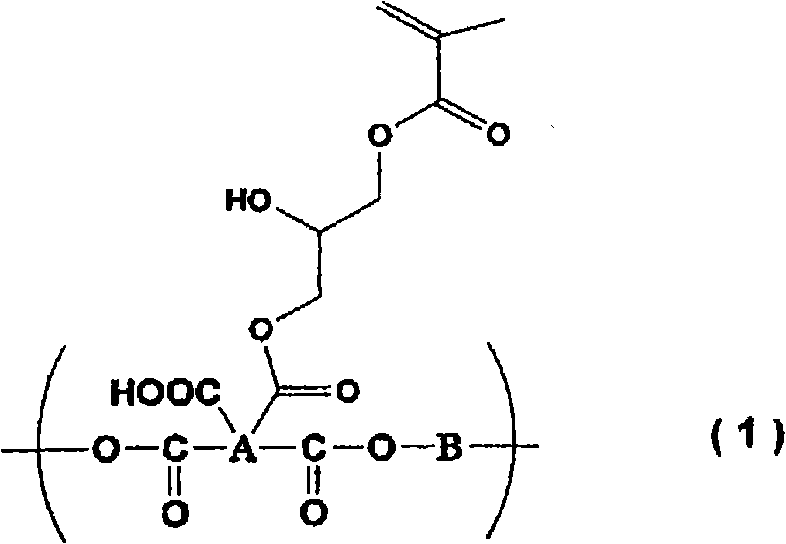

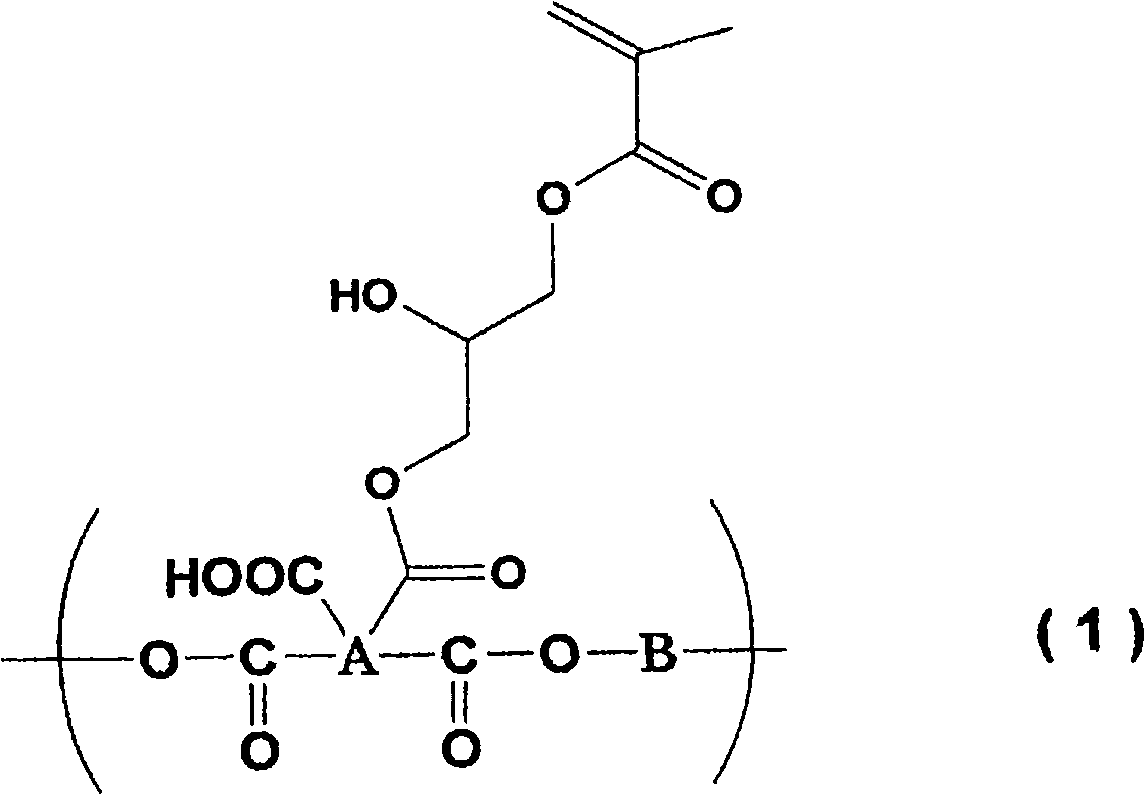

To provide a material which can be formed into a cured film having high solvent resistance, liquid crystal-aligning properties, high transparency and high planarization, and which can be dissolved in a glycol-type solvent and is therefore applicable in the production line for a planarized film of a color filter when used in the formation of a cured film from the material. Disclosed are: a polyester resin solution for the production of a thermally cured film, which comprises a polyester polymer having a structural unit represented by the formula (1); and a cured film, a liquid crystal alignment layer and a planarized film each of which is produced from the polyester resin solution. (1) wherein A and B independently represent an organic group containing a ring structure.

Description

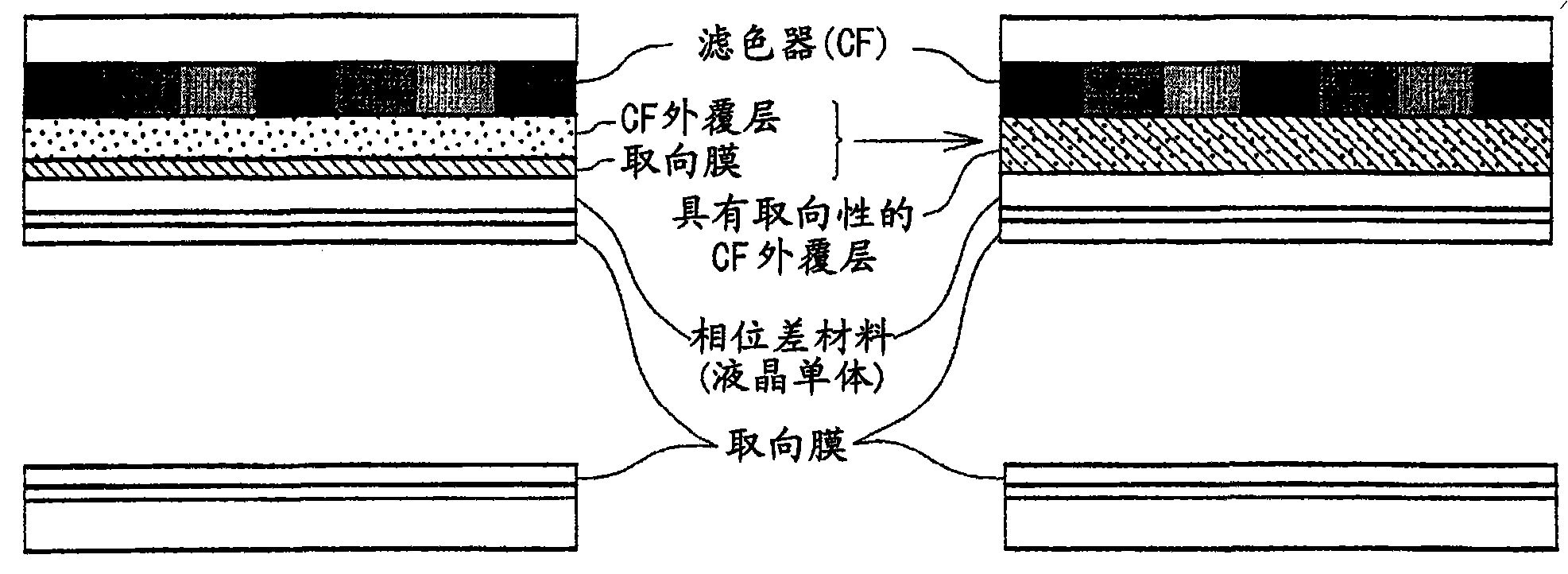

technical field The present invention relates to a thermosetting film-forming polyester resin solution and a cured film obtained from the thermosetting film-forming polyester resin solution. More specifically, the present invention relates to a polyester resin solution for forming a thermosetting film, the cured film, and uses of the cured film for forming a thermosetting film having high transparency, planarization, and liquid crystal orientation ability . This resin solution for thermosetting film formation is especially suitable for the color filter overcoating agent which has the function of the liquid crystal alignment in a liquid crystal display. Background technique Generally, in optical devices such as liquid crystal display elements, organic EL (electroluminescent) elements, and solid-state imaging elements, a protective film is provided on the surface of the element to prevent exposure to solvents or heat during the manufacturing process. Such a protective film n...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08G63/123C08G63/91C08F299/04C09D167/06G02F1/1333G02F1/1337

CPCG02F2202/025G02F2001/133519C08G63/21C08F299/00G02F1/133711C08F299/04C08G63/123G02F1/133519

Inventor 畑中真安达勲

Owner NISSAN CHEM IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com