Cover glass for watch

A watch and protective cover technology, applied in the field of watch cover glass, can solve the problems of anti-reflection film damage, peeling, surface blur, etc., and achieve the effect of improving wear resistance and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

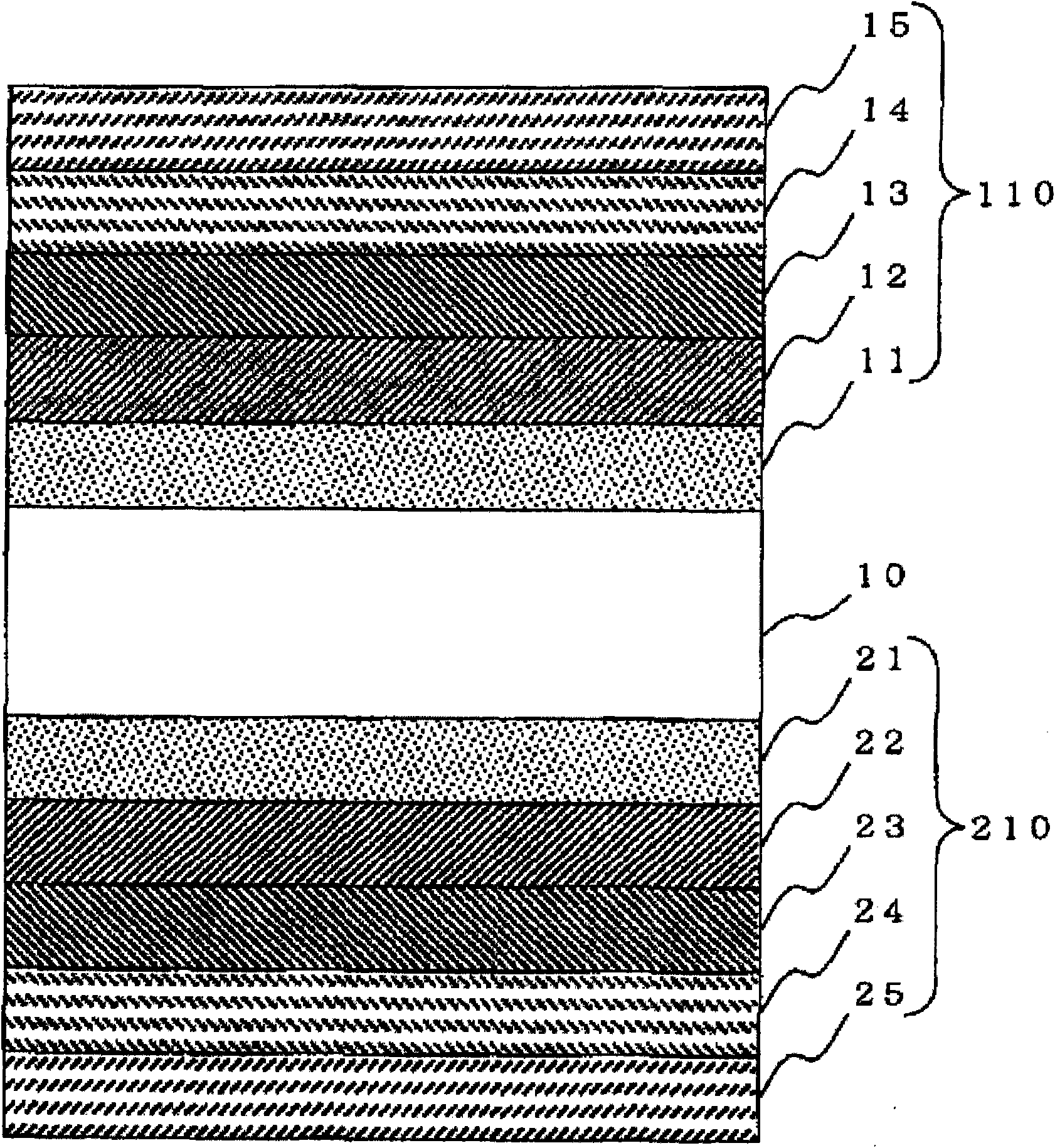

[0070] The watch cover glass according to Embodiment 1 of the present invention includes a transparent base material having a front surface and a back surface, and an antireflection film laminated on both surfaces of the front surface and the back surface.

[0071] (transparent substrate)

[0072] Examples of the base material include blue plate glass (soda glass), white plate glass, synthetic quartz, sapphire glass, and transparent plastics. Examples of transparent plastics include polycarbonate, methyl methacrylate resin, polystyrene, polyethylene terephthalate, and the like.

[0073] The thickness of the substrate is usually 200 to 4000 μm.

[0074] In addition, in this specification, the front side of the base material refers to the surface exposed to the outside air when the watch cover glass of Embodiment 1 is used for a timepiece; The surface opposite to the dial when the cover glass is used for a watch.

[0075] (anti-reflection film)

[0076] The anti-reflection f...

Embodiment approach 2

[0099] The watch cover glass according to Embodiment 2 of the present invention includes a transparent base material having a front surface and a back surface, and an antireflection film laminated on both of the front surface and the back surface.

[0100] (transparent substrate)

[0101] The substrate used in the second embodiment of the present invention is the same as that in the first embodiment.

[0102] (anti-reflection film)

[0103] The antireflection film used in Embodiment 2 is formed by coating Si from the substrate to the outermost layer. 3 N 4 The film and the mixed film are laminated in this order in four layers alternately, and the outermost layer is the mixed film. That is, the antireflection films on the front and back have the following composition from the substrate side: Si 3 N 4 Membrane / Hybrid Membrane / Si 3 N 4 Membrane / Hybrid Membrane. In addition, the anti-reflection film on the front side can be laminated with a total of 6, 8, 10 or 12 layers o...

Embodiment approach 3

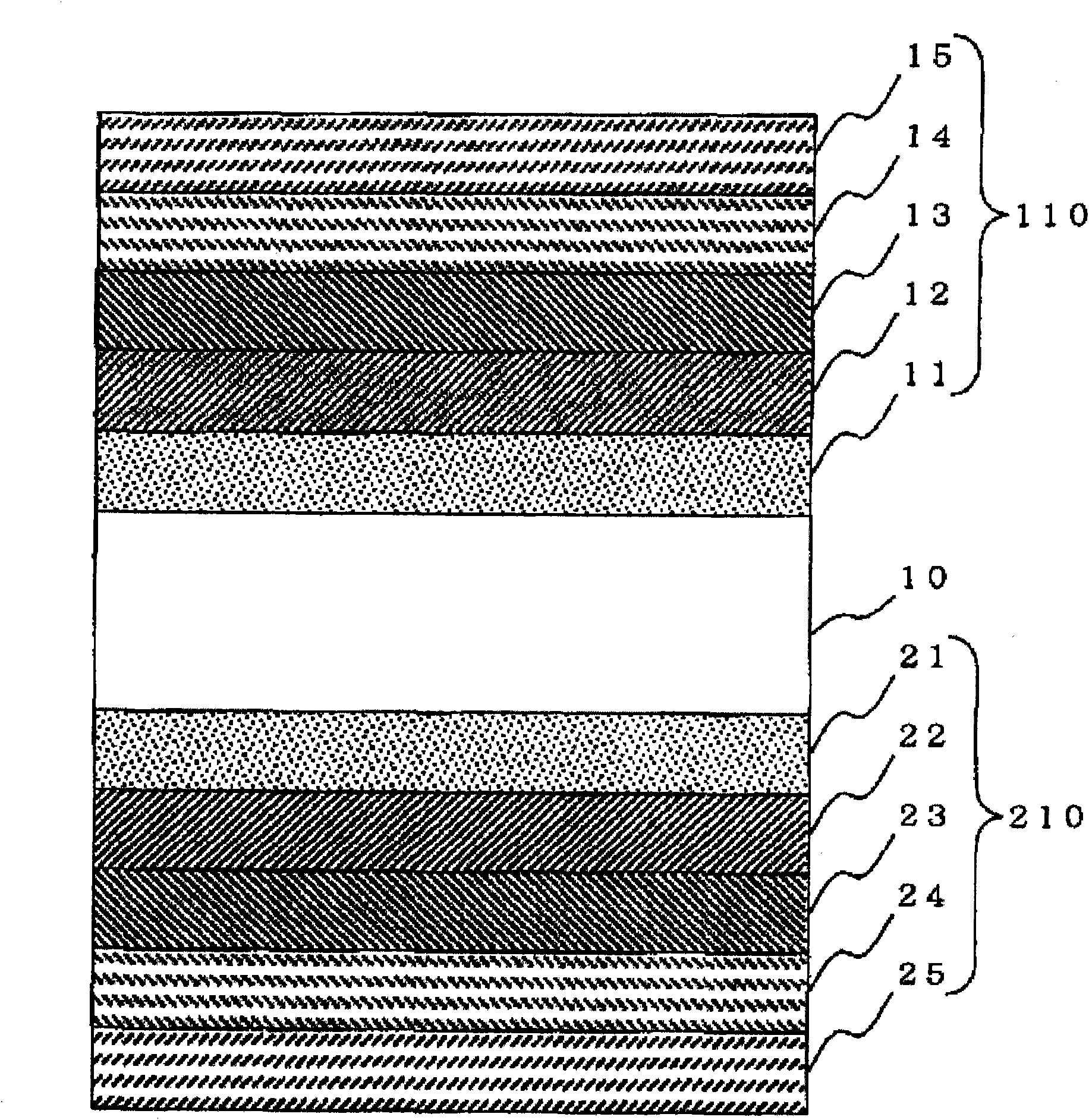

[0115] The watch cover glass according to Embodiment 3 of the present invention includes a transparent base material having a front surface and a back surface, and an antireflection film laminated on the back surface.

[0116] (transparent substrate)

[0117] The substrate used in the third embodiment of the present invention is the same as that in the first embodiment.

[0118] (anti-reflection film)

[0119] The antireflection film used in Embodiment 3 is formed by combining a mixed film with Si from the substrate to the outermost layer. 3 N 4 The film is formed by laminating five layers alternately in this order, and the outermost layer is a mixed film. That is, as shown in FIG. 8 , the antireflection film on the back has the following structure from the substrate side: mixed film 21 / Si 3 N 4 Membrane 22 / Hybrid Membrane 23 / Si 3 N 4 Membrane 24 / Hybrid Membrane 25 . In addition, the anti-reflection film on the back can be laminated with a total of 7, 9 or 11 layers ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectivity | aaaaa | aaaaa |

| reflectivity | aaaaa | aaaaa |

| reflectivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com