Fixed large-bale straw baler

A fixed, baler technology, which is applied in baling, agricultural machinery and tools, threshing equipment, etc. It can solve the problems of many shipping procedures, low production efficiency, and low baling density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The technical solution of the present invention will be further described in more detail below in conjunction with the accompanying drawings and specific embodiments:

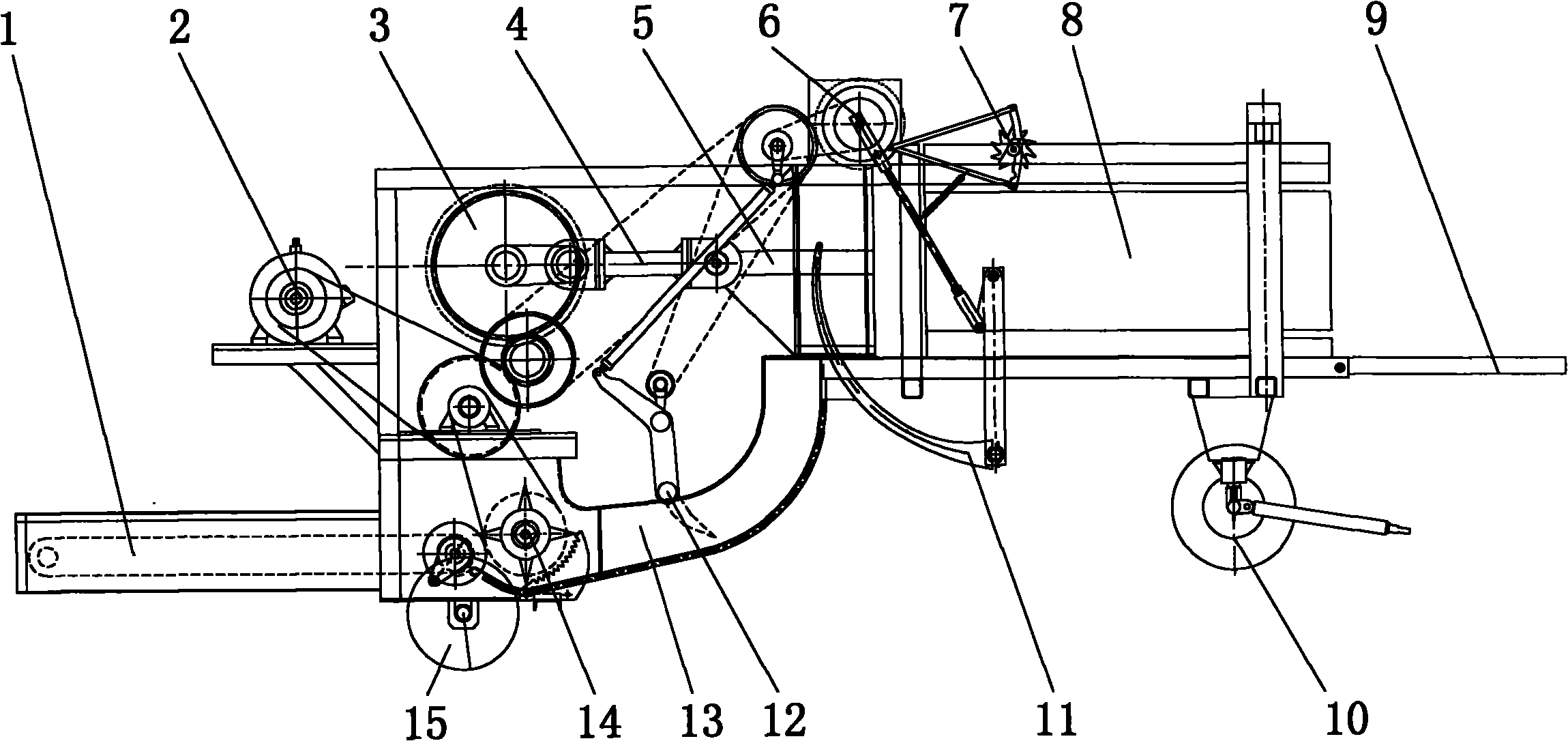

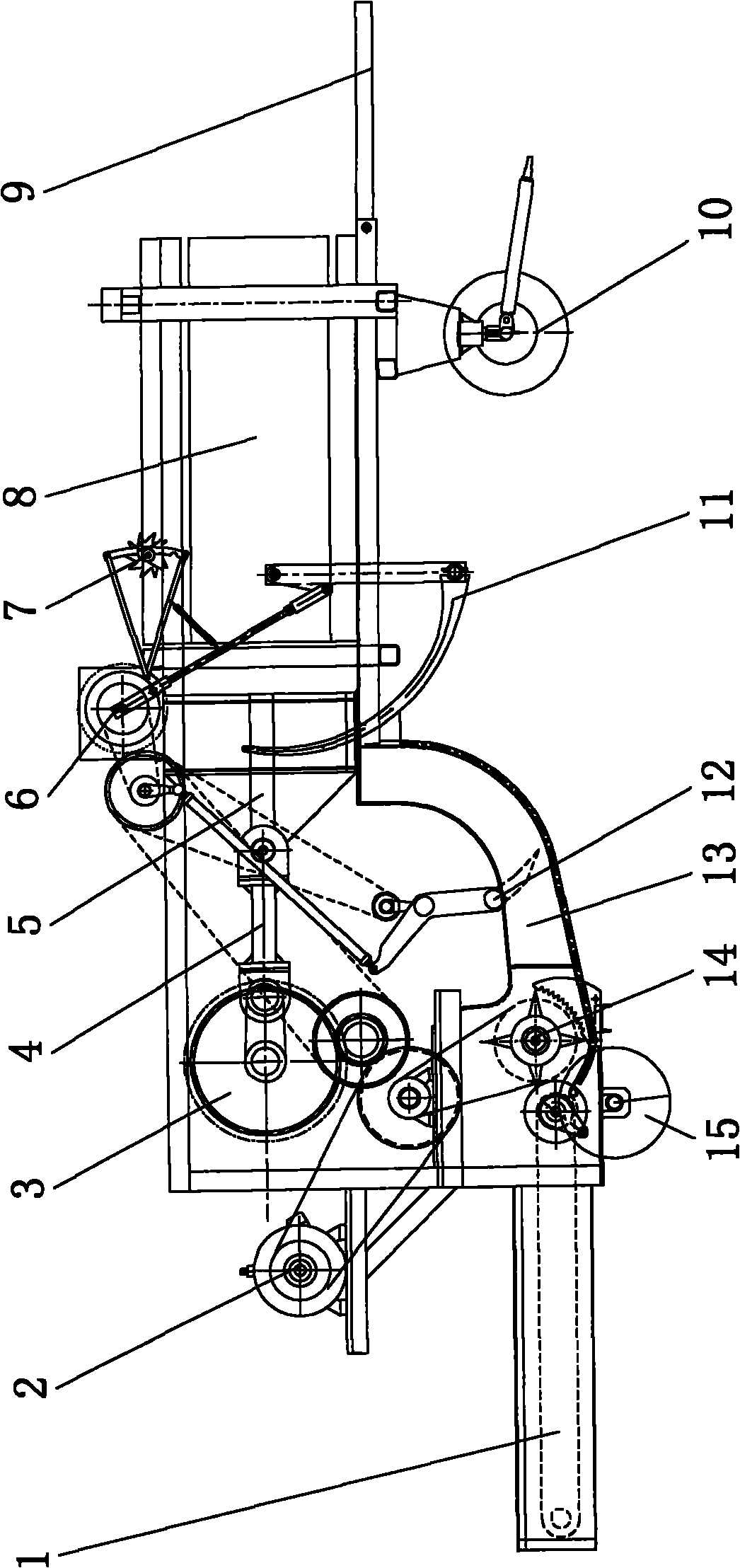

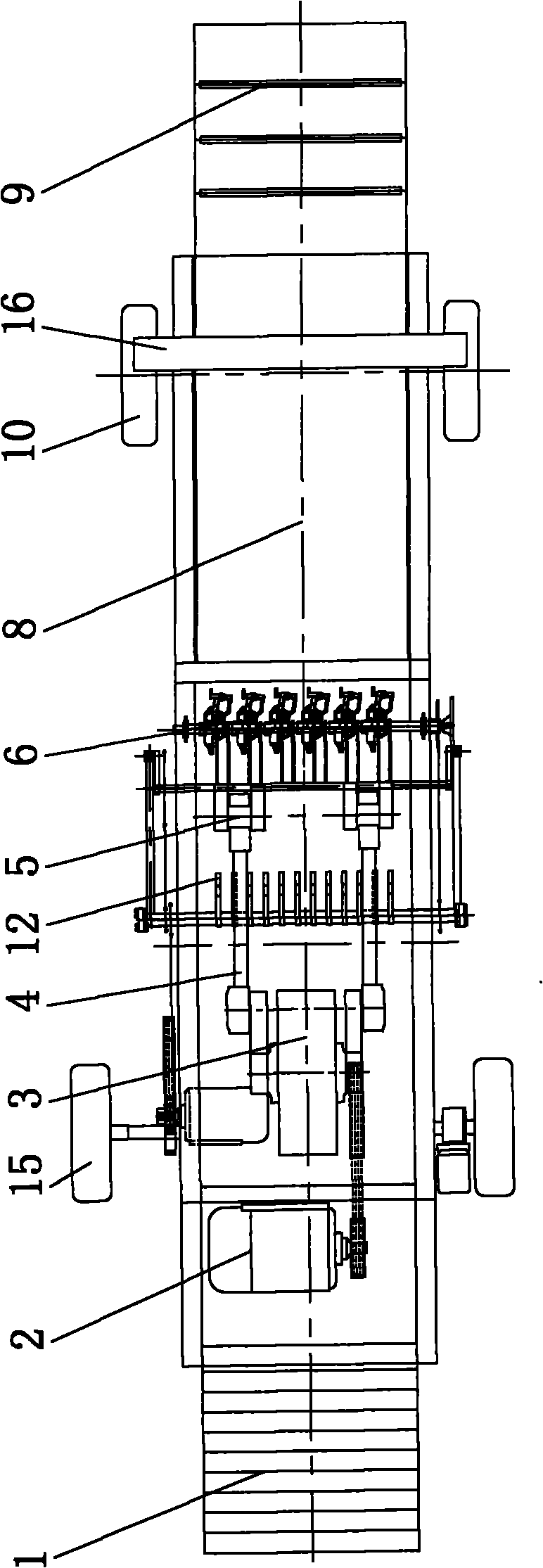

[0087] Please refer to Fig. 1 and Fig. 2 in the general structural diagram of the present invention.

[0088] In the specific embodiment shown in the figure, the fixed large-bale straw baler of the present invention includes: a feeding conveying device 1 installed on the frame, a power drive device 2, a gearbox 3, a crankshaft 31, a connecting rod 4 and the reciprocating compression device composed of piston 5, chopping device 14, filler shift fork 12, material pre-compression chamber 13, bale length regulator 7, double knotting mechanism 6, knotting needle 11, compression chamber 8, outlet Bundle chute 9, rear support wheel 10, front support wheel 15. The feeding conveying device 1 is sequentially connected with the chopping device 14, the pre-compression chamber 13, the compression chamber 8 and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com