Etching solution and etching method

An etching solution and anion technology, applied in the field of etching, can solve the problem of small damage to ITO, and achieve the effect of small damage

Active Publication Date: 2010-08-25

深圳市合力泰光电有限公司

View PDF0 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to solve the technical problem that the existing technology cannot simultaneously solve the aluminum and chromium composite metal deposition layer on the surface of indium tin oxide (ITO) to be etched to form a circuit, while the ITO is less damaged, the invention provides an etching solution, Its ingredients, based on its total weight, include:

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

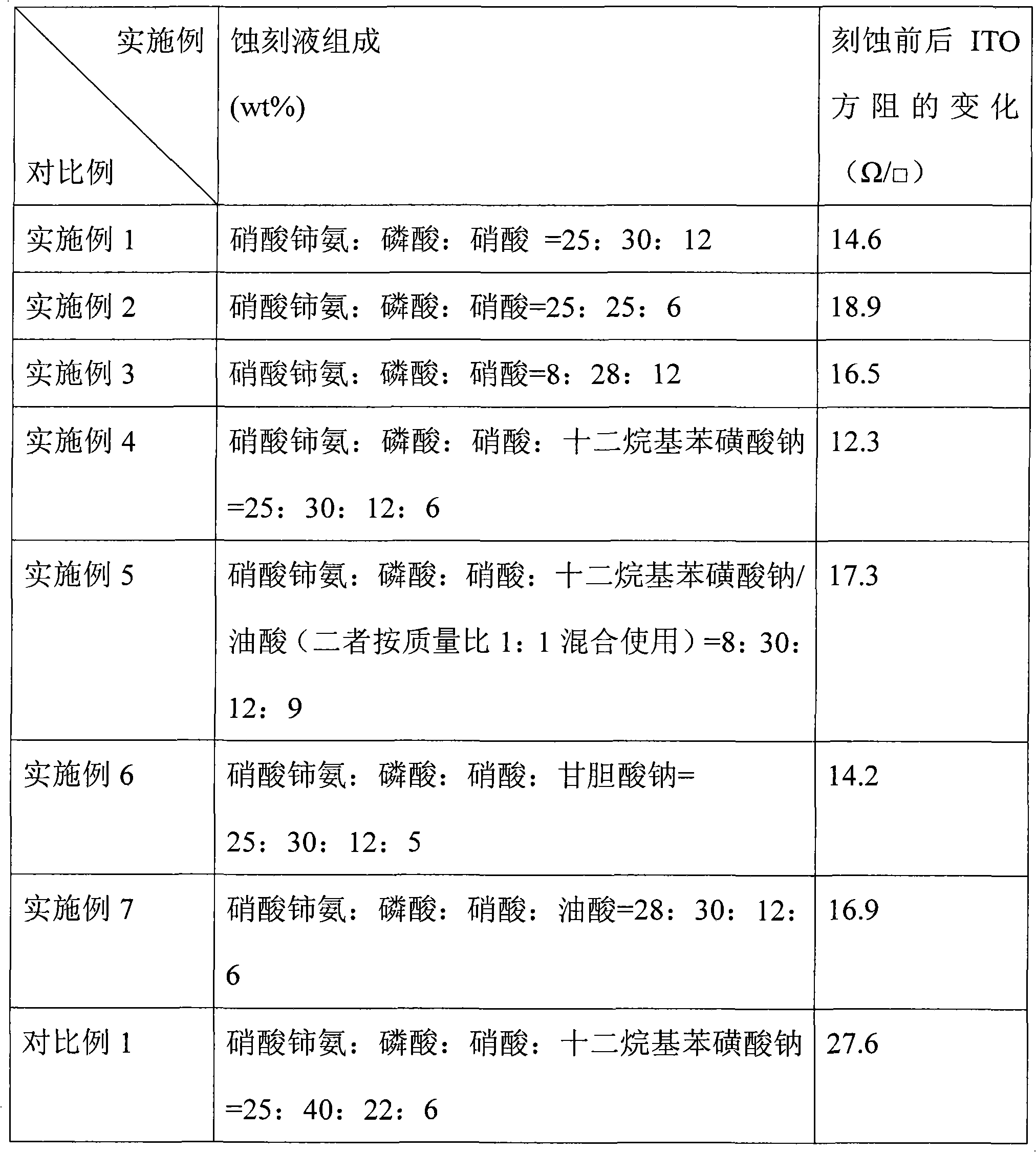

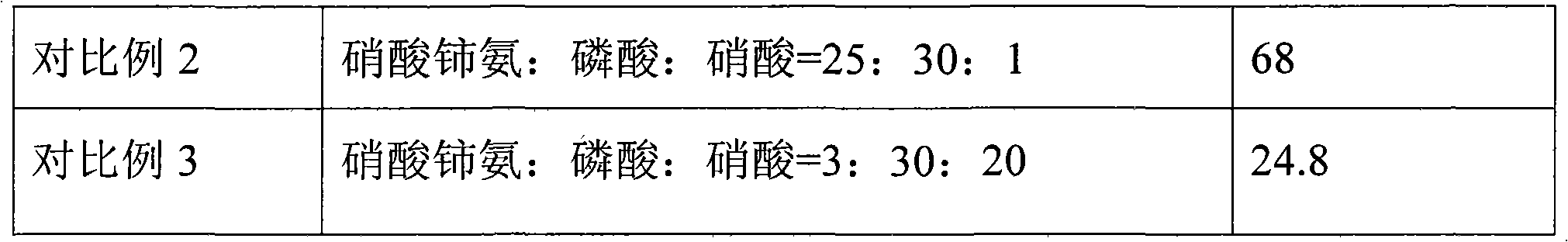

Login to View More Abstract

The invention provides etching solution, which comprises the following components in percentage by weight: 5 to 30 percent of cerium ammonirm nitrate, 10 to 40 percent of phosphoric acid and 2 to 20 percent of nitric acid. The etching solution has little damage to an indium tin oxide electrode when etching an Al-Cr composite metal deposition layer on the surface of the indium tin oxide electrode.

Description

technical field The invention relates to an etching solution and an etching method using the etching solution. Background technique Metal aluminum is often used to form circuits on the surface of indium tin oxide (ITO) substrates due to its good electrical conductivity. However, due to some problems of pure aluminum or aluminum alloy itself, metal chromium or chromium alloy is commonly used together with aluminum or aluminum alloy to form an aluminum and chromium composite metal deposition layer on the surface of ITO, and then etched to form a circuit. For example, due to the low strength of pure aluminum or aluminum alloy, it is easy to be scratched and cause an open circuit when making a circuit, so a layer of protective chromium or chromium alloy is often plated on the aluminum or aluminum alloy deposition layer; in addition, aluminum or aluminum alloy is directly The adhesion is low when it is plated on ITO, so a layer of chromium or chromium alloy is plated under the a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23F1/16C23F1/20

Inventor 舒滔

Owner 深圳市合力泰光电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com