Offshore single-pile base structure and installation method thereof

A single-pile foundation and installation method technology, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of high cost, many pile legs, and long construction period, and achieve simple construction, material saving, and material saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

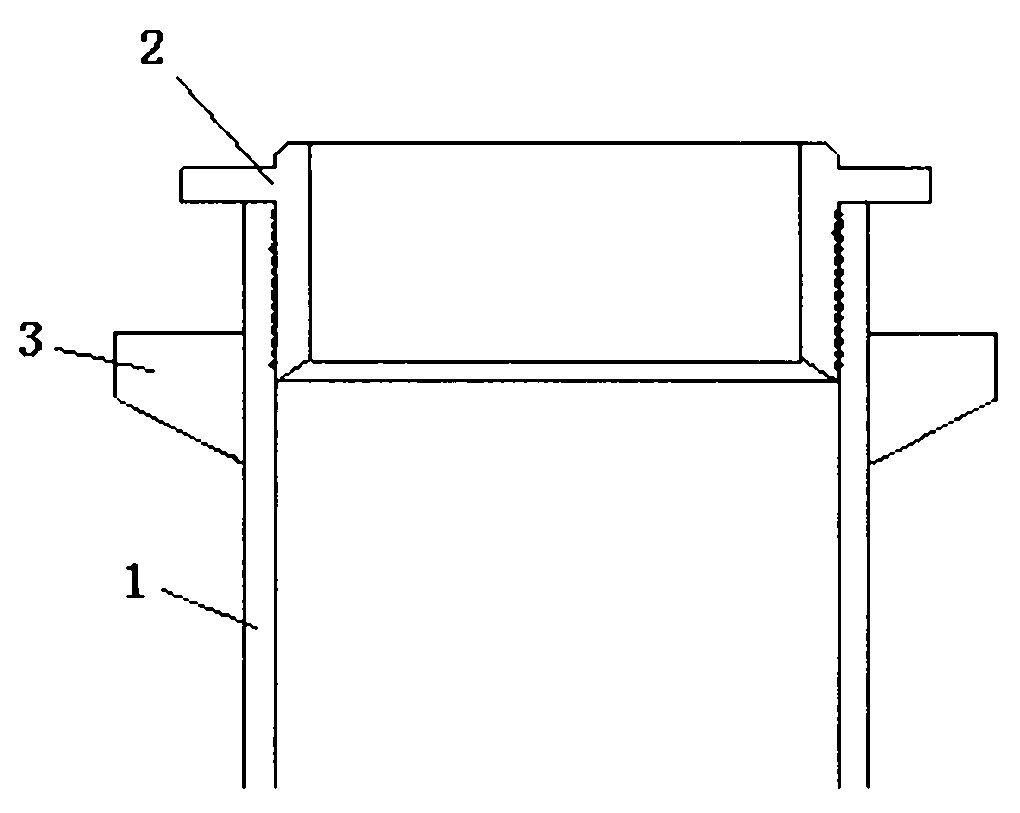

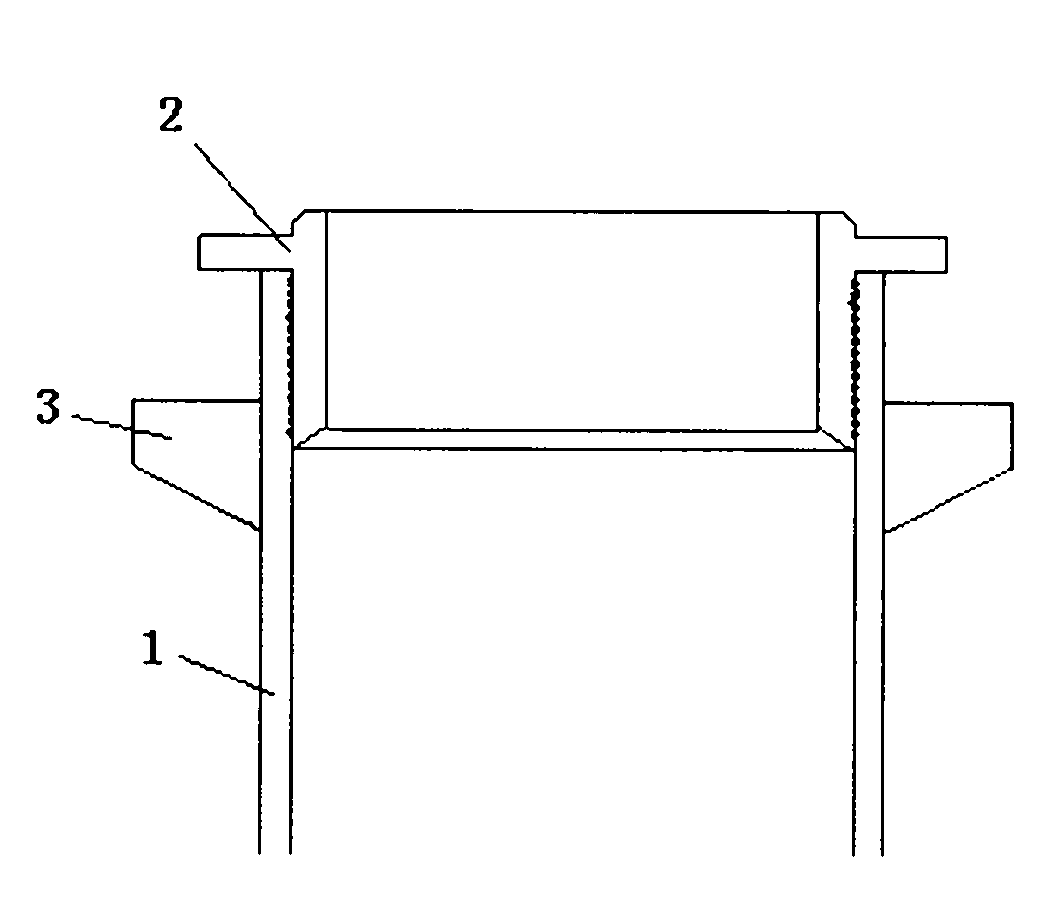

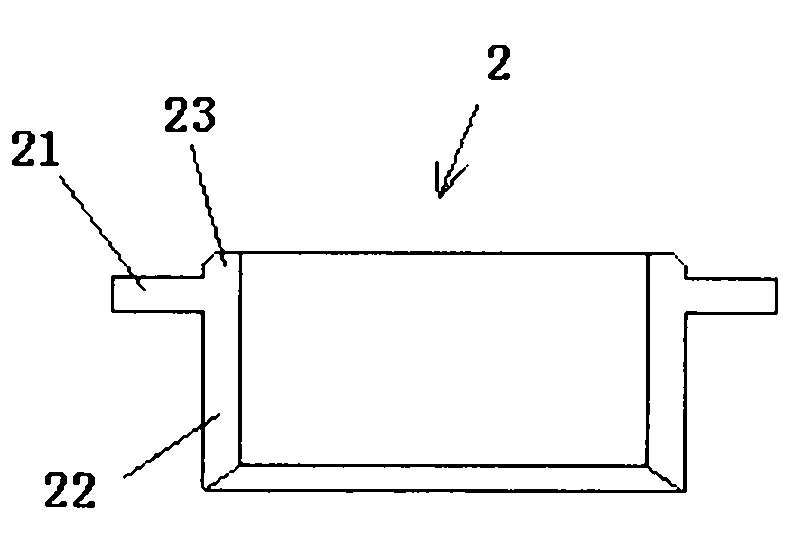

[0022] As shown in Figure 1, the main body of the single pile foundation structure of the present invention is a large-diameter (3m-6m) steel pipe pile 1. out of the water. A flange member 2 is welded at the upper end of the steel pipe pile 1 . As shown in FIG. 2 , the flange member 2 is composed of a flange 21 , a flange neck 22 and a boss 23 , wherein the boss 2 can be formed by the flange neck 22 itself. In the factory, the flange neck 22 is consolidated on the annular inner wall of the flange 21, and the upper part of the flange neck 22 protrudes from the flange 21 to form a boss 23; or the flange neck 22 and the flange 21 are pressed together The above form can be integrally forged as a whole.

[0023] The flange member 2 is welded on the steel pipe pile 1 through the flange neck 22, and the flange neck 22 can be welded on the inner wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com