Jet-grouting pipe-shed pre-support method for tunnel and longitudinal opening perforated pipe

A technology of longitudinal opening and pre-support, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., and can solve problems such as extended construction period, long period, and strict construction space requirements

Active Publication Date: 2010-08-25

UNIV OF SCI & TECH BEIJING

View PDF4 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

With the rapid development of tunnel engineering, these two pre-support technologies are becoming more and more mature. However, in some engineering sites with particularly poor geological conditions, if only high-pressure rotary grouting or pipe shed support is used alone, effective support cannot be achieved. Pre-support effect of

The literature [Advance support technology of all-round high-pressure jet grouting arch shed. Liu Zhong, Liu Jianguo, Zhang Yi, Li Zhiyi, Journal of Rock Mechanics and Engineering, 2009 01] shows that large hydraulic double rocker arm type has been developed domestically. The all-round high-pressure jet grouting drilling rig realizes the integrated technology of drilling and rotary grouting, and achieves the purpose of fast and effective construction. The technology is post-reinforcement technology. Generally, most of the water-rich and loose soil layers encountered in tunnel excavation are unfavorable rock and soil bodies containing pebbles and gravels. The huge injection force of the rotary spraying leads to the filling of pebbles, gravels, etc. in the borehole, and the rear insertion of the reinforcement will not be possible. The rocker-arm type omni-directional high-pressure jet grouting drilling rig is used for construction, which has strict requirements on construction space and high cost

If the traditional combination process is adopted, the above two construction methods are used comprehensively for tunnel pre-support, that is, the rotary grouting support is carried out first, and then the pipe shed is constructed. Both sets of processes require rock drilling to form holes, and the construction cost is equivalent to the two Simple superposition of independent processes, and drilling is the process with the highest cost and the longest cycle among the two process links, and the process cycles are intersected with each other, which further leads to low work efficiency and greatly extended construction period

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

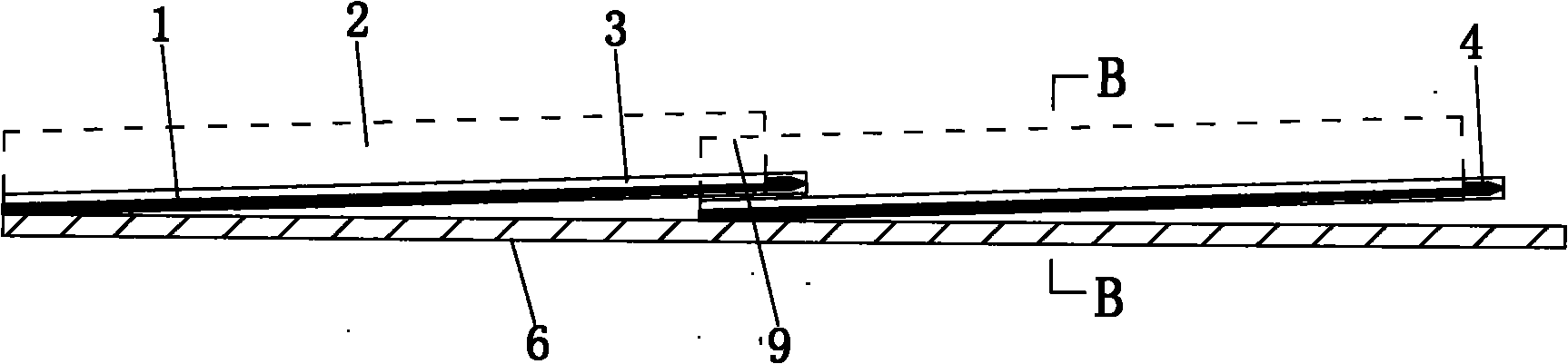

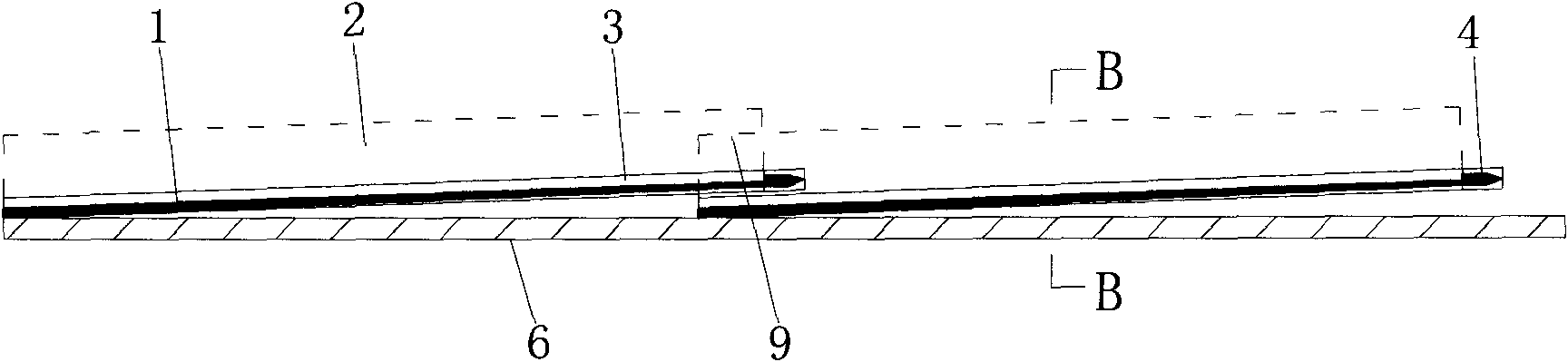

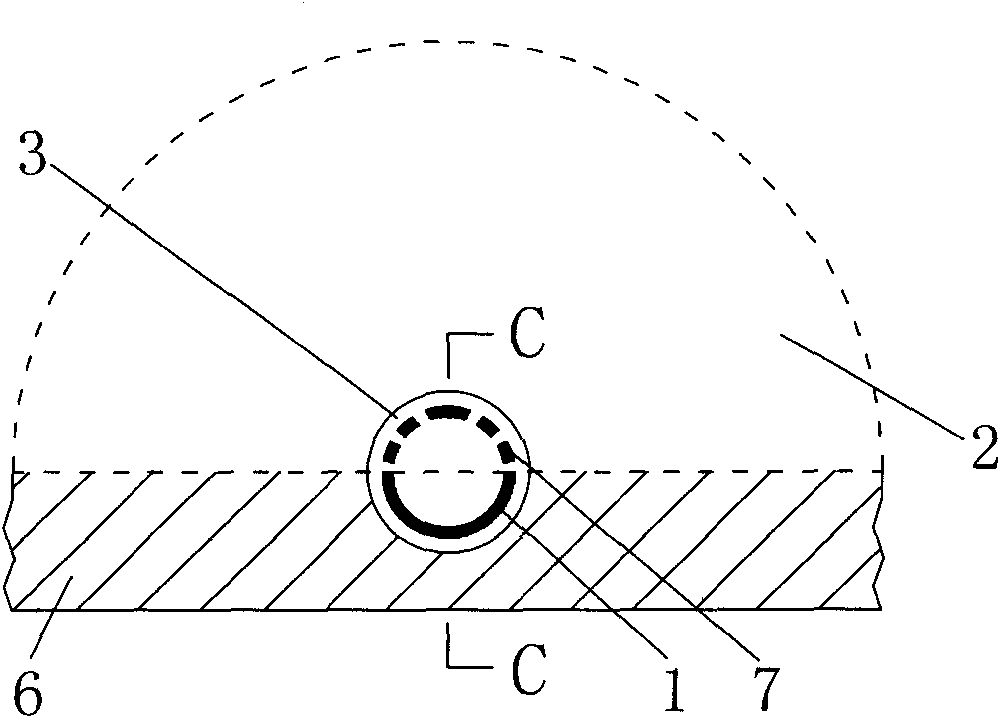

Login to View More Abstract

The invention belongs to the technical field of civil engineering support, and particularly relates to a pre-support method for a tunnel having undesirable stratums, particularly water-rich stratums and a special tool for the method. The method mainly comprises the following steps of: 1.1 drilling, namely drilling along the designed periphery of the tunnel at intervals of 0.3 to 1.0m during construction, wherein the drilled holes are horizontal or in an inclination angle below 10 degrees; 1.2 inserting a longitudinal opening perforated pipe into each of the drilled holes and making the bottom of the longitudinal opening perforated pipe adjacent to the designed excavating boundary of the tunnel; 1.3 placing a high-pressure jet-grouting nozzle into one of the drilled holes to perform high-pressure jet-grouting operation; and 1.4, performing jet-grouting to form a plurality of jet-grouting bodies, wherein a pre-support arched shed structure is formed by the plurality of jet-grouting bodies and the longitudinal opening perforated pipe, and the inner liners of the tunnel, the longitudinal opening perforated pipe and the jet-grouting bodies are tightly combined to form an effective support structure. The invention also discloses the special tool for the method.

Description

Pre-supporting method for tunnel rotary spray tube shed and longitudinal opening flower tube Technical field The invention belongs to the technical field of civil engineering support, and particularly relates to a method for pre-supporting a tunnel in a bad stratum, especially a stratum rich in water, and a special tool used in the method. Background technique In tunnel construction, in order to give full play to the self-supporting capacity of the surrounding rock and ensure safe construction, pre-supporting is necessary before excavation. For hard surrounding rocks and other surrounding rocks with good stability, advance pre-support is generally not required. The main support method used in the excavation construction process is bolting and shotcrete support. For weak and broken surrounding rocks with poor self-stability, advanced pre-supporting methods such as advanced bolts, pipe sheds, small pipes advanced grouting and pre-reinforcement, and mechanical pre-cut groove meth...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E21D11/00E21D11/38

Inventor 吴顺川高永涛

Owner UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com