Hydraulic CNG (Compressed Natural Gas) gas filling substation and pipeline system, control system and control method thereof

A technology of gas filling sub-station and pipeline system, which is applied in pipeline system, liquid distribution, conveying or transfer device, gas/liquid distribution and storage, etc. Adaptability and the effect of improving the air intake rate of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

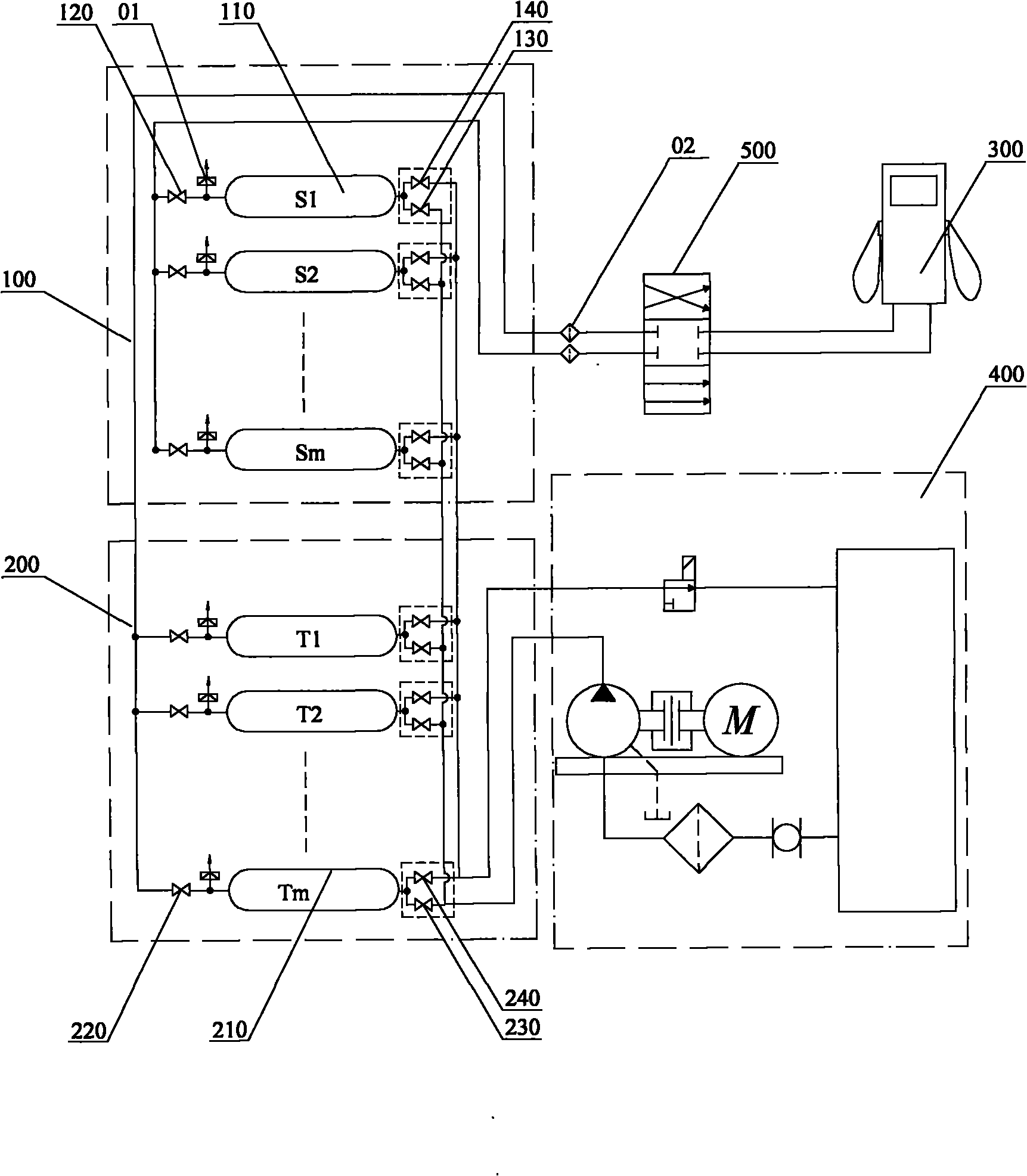

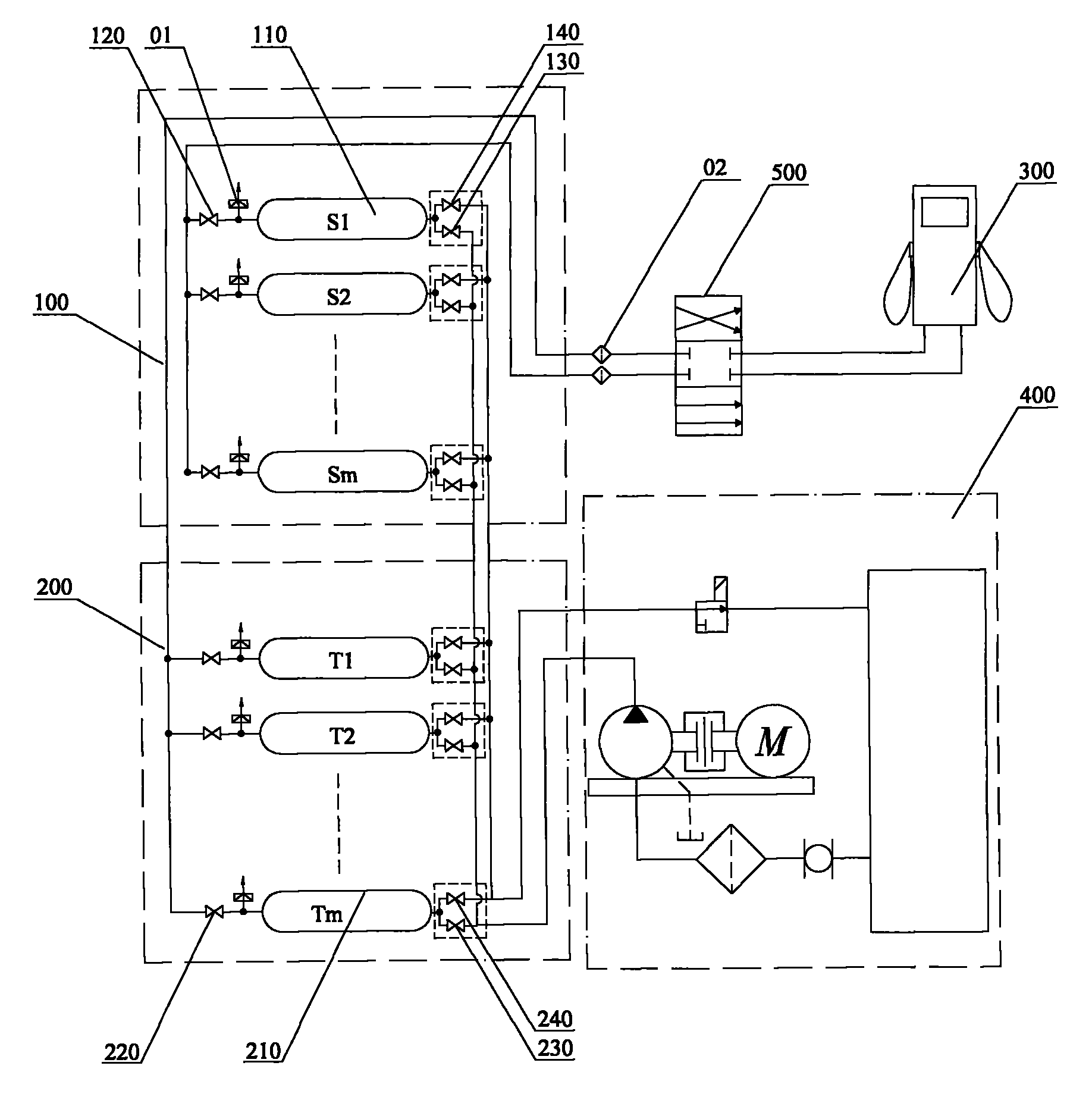

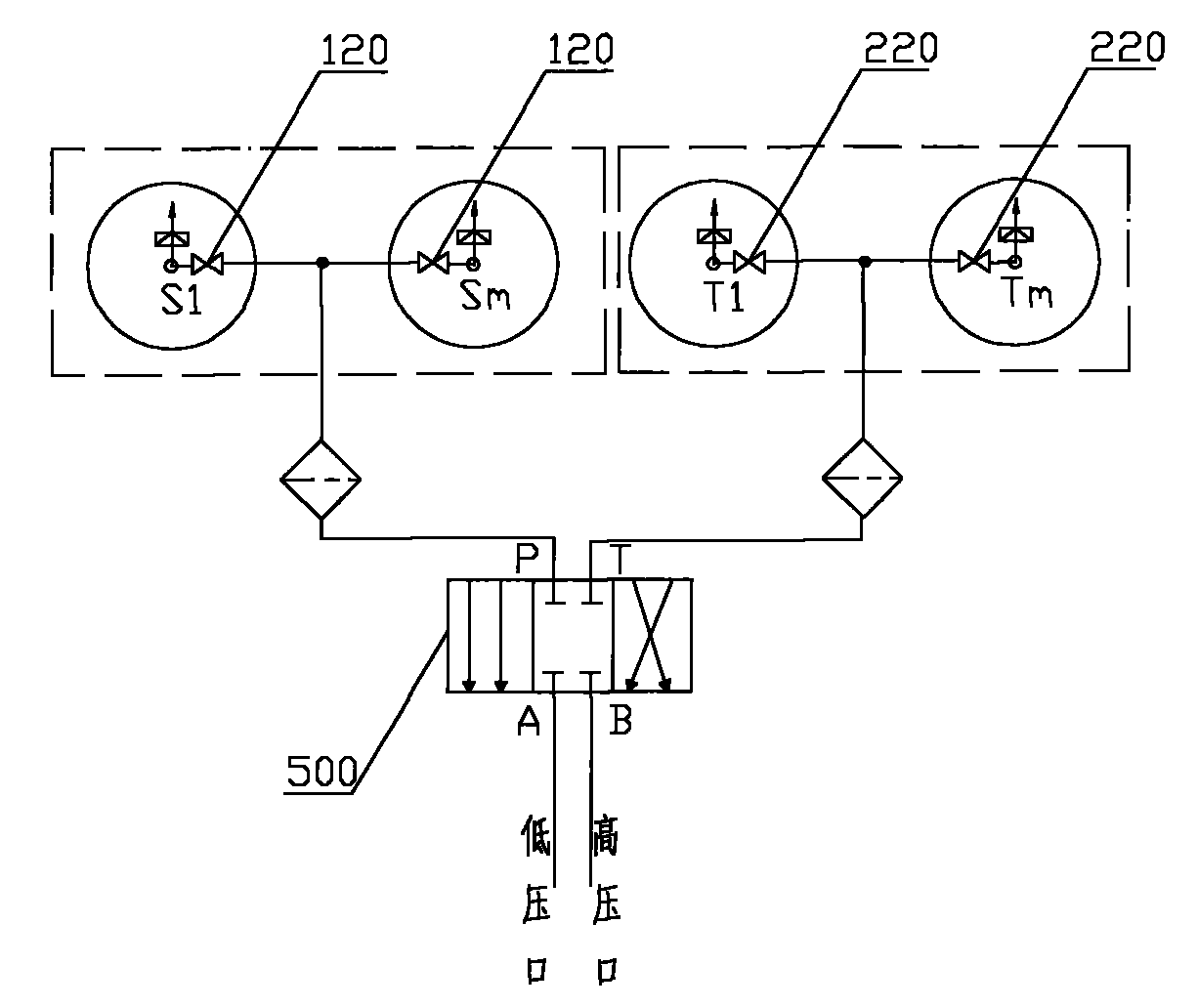

[0038] The pipeline system of the hydraulic CNG filling substation provided in Embodiment 1 includes a gas storage mechanism, a gas filling machine 300 , a boosting mechanism 400 and a distribution valve 500 .

[0039] The gas storage mechanism includes a plurality of gas storage cylinders, and according to different connections, the multiple gas storage cylinders form two groups, called the first gas storage cylinder group 100 and the second gas storage cylinder group 200 . The first gas storage cylinder set 100 includes a plurality of first gas storage cylinders 110, and the plurality of first gas storage cylinders are respectively marked as S1, S2...Sm. Similarly, the second gas storage cylinder group 200 includes a plurality of second gas storage cylinders 210, and the plurality of second gas storage cylinders are marked T1, T2...Tm respectively. Among them, m is an integer.

[0040] On the one hand, the pipeline system is provided with a plurality of output control valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com