Strain gauge water-proof sealing method and structure thereof

A waterproof sealing and strain gauge technology, applied in the field of inspection, can solve the problems of inability to effectively seal the strain gauge, shorten the operation time, etc., and achieve the effect of shortening the sealing operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

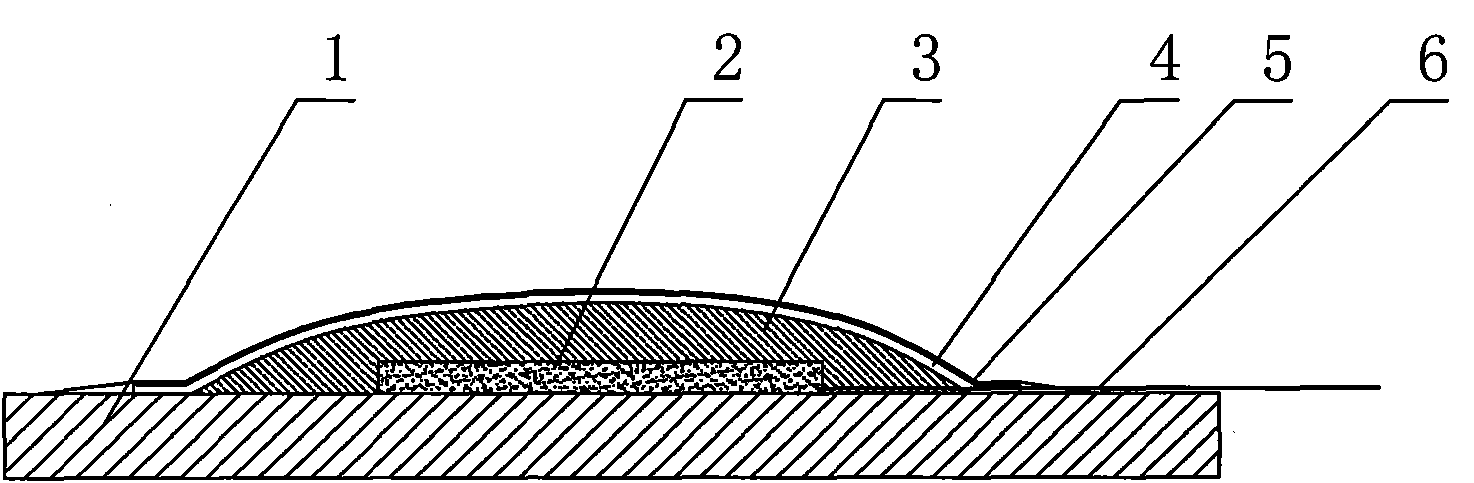

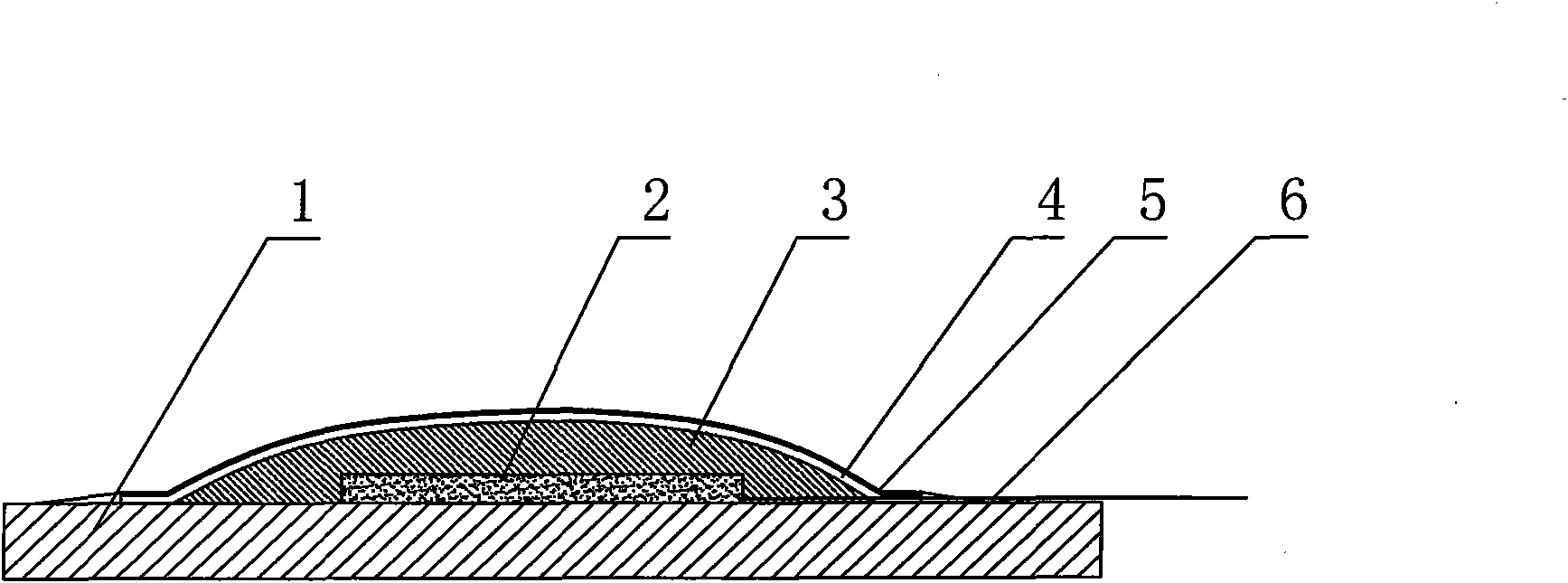

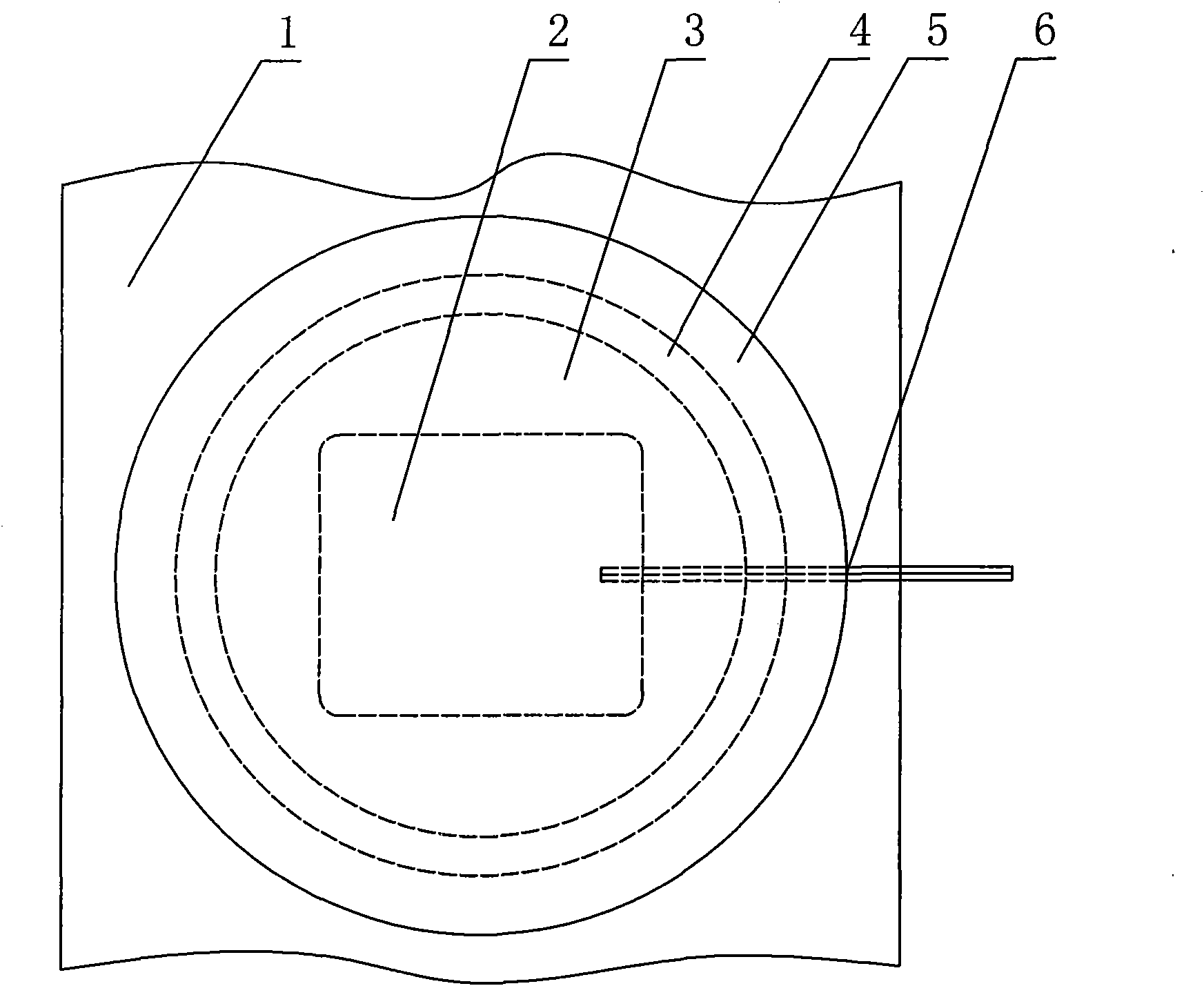

[0017] The strain gauge waterproof sealing method of the present invention comprises the following specific steps:

[0018] Step 1: Partially grind the area to be tested on the surface of the tested structure 1 to remove the oxide film on the surface and perform polishing treatment to make the surface basically smooth;

[0019] Step 2: Use acetone or other cleaning agents to clean the polished area of the surface of the tested structure 1 several times to remove oil and dust;

[0020] Step 3: Use instant glue to firmly paste the strain gauge 2 on the surface of the tested structure 1 after polishing and cleaning;

[0021] Step 4: Weld the measuring wire 6 and the terminal of the strain gauge 2 firmly;

[0022] Step 5: Paste the SB type waterproof sealant 3 on the surface of the strain gauge 2, put the anti-adhesive paper on it and press it with your fingers until the SB type waterproof sealant 3 evenly covers the strain gauge 2, the connection terminals and some of the meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com