Method for primary sealing and secondary sealing protection of gas circuit interface of isotope thermoelectric cell

A thermoelectric battery and secondary sealing technology, which is applied in the field of secondary sealing protection and the sealing of the atmosphere disposal interface, can solve the problems of air hole leakage, damage, and long time at the welding port, and achieve good ductility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

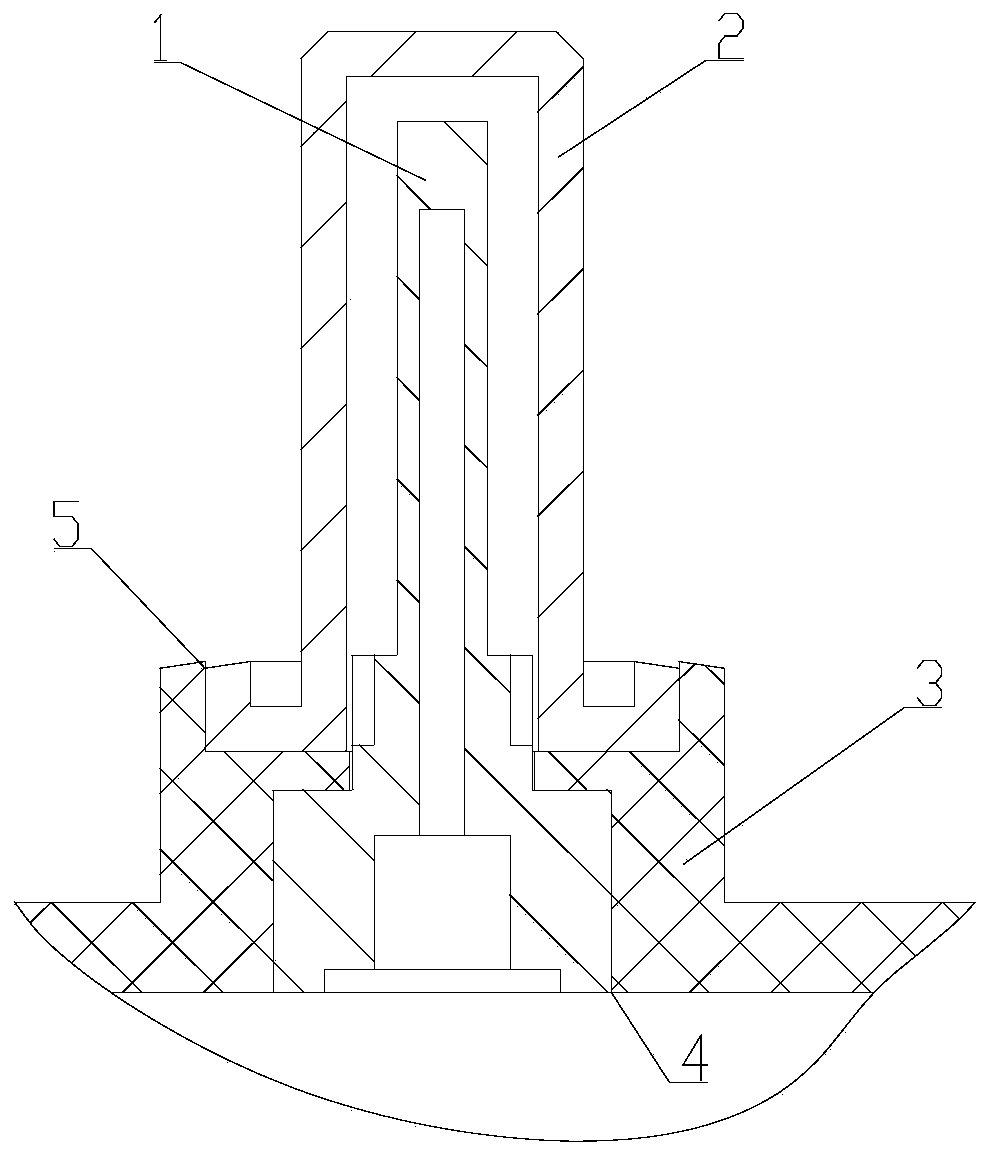

[0029] An embodiment of the present invention provides a method for primary sealing and secondary sealing protection of the gas circuit interface of an isotope thermoelectric battery, including the following steps:

[0030] S1, Manufacturing atmosphere disposal interface 1 and protective cap 2

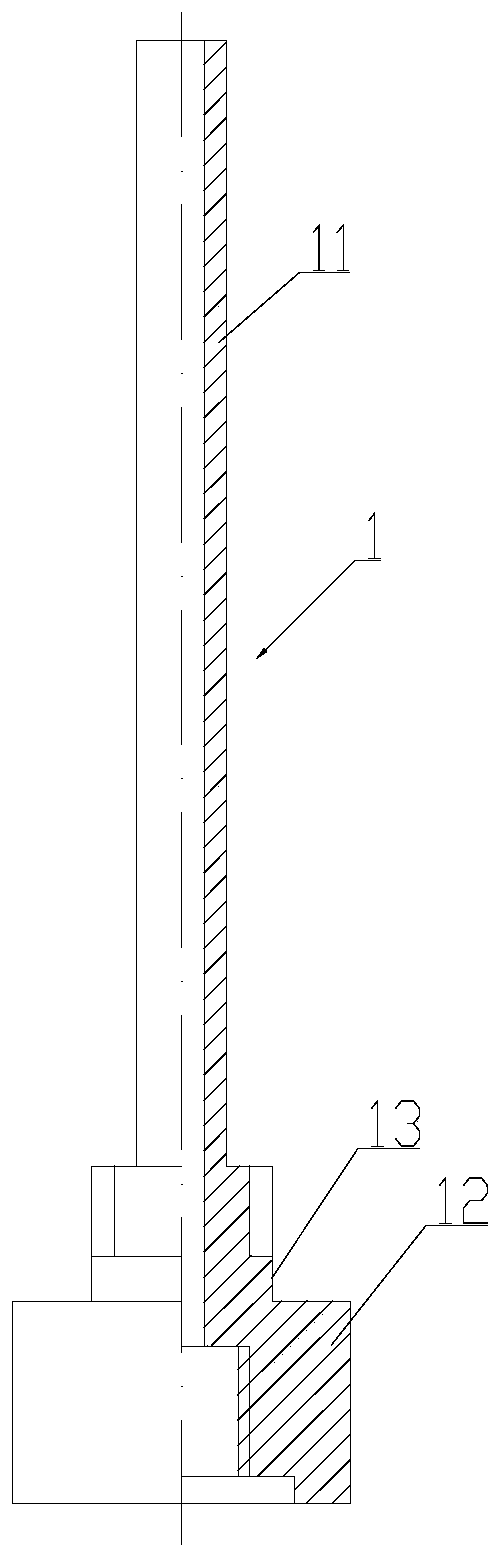

[0031] Manufacture of the atmosphere treatment interface 1: use 2A16H aluminum alloy material pipe fittings for turning and drilling to form a thin-walled pipe 11 with a wall thickness of 0.8 mm to 1.2 mm at the upper end and a pipe length ≥ 50 mm at the upper end, and a short step with a thread 13 at the lower end Tube 12, structured as figure 1 shown.

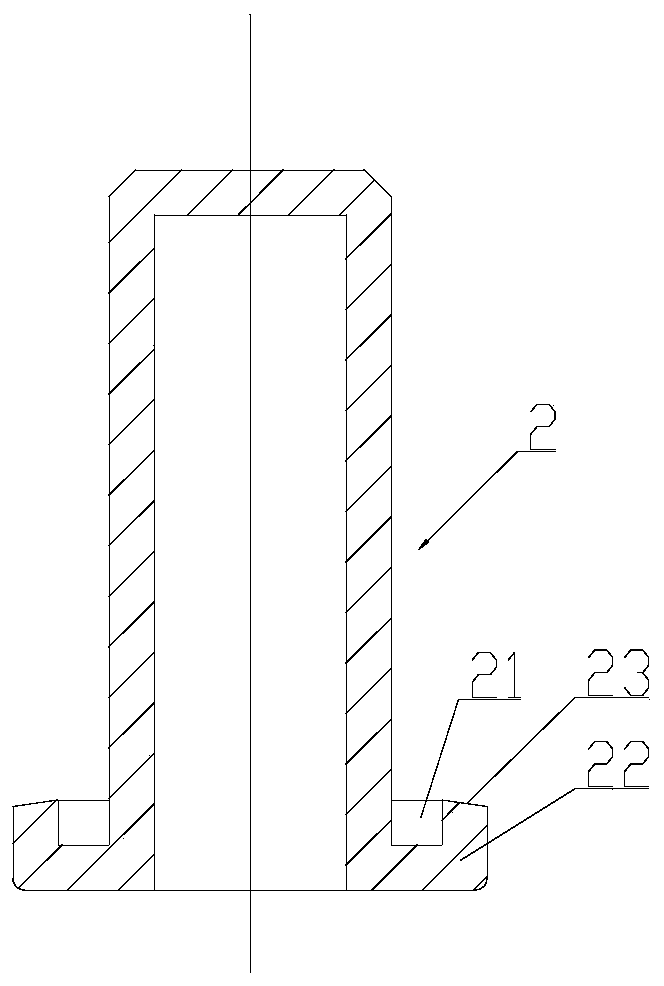

[0032] Manufacture of protective cap 2: use 2A16H state aluminum alloy pipe fittings for turning to form a cavity inside, the upper end is a pipe cap with a wall thickness of 2 mm, and the lower end is a pipe cap with an independent groove 21 that is folded outward and extends upward, and the groove The top outer end surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com