Piston pump for conveying a fluid and associated braking system

A technique for piston pumps and piston parts, which is applied to components of pumping devices for elastic fluids, brakes, liquid fuel engines, etc., can solve problems such as weakening strength, and achieve reduced component loads, favorable costs, and the most structural space good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

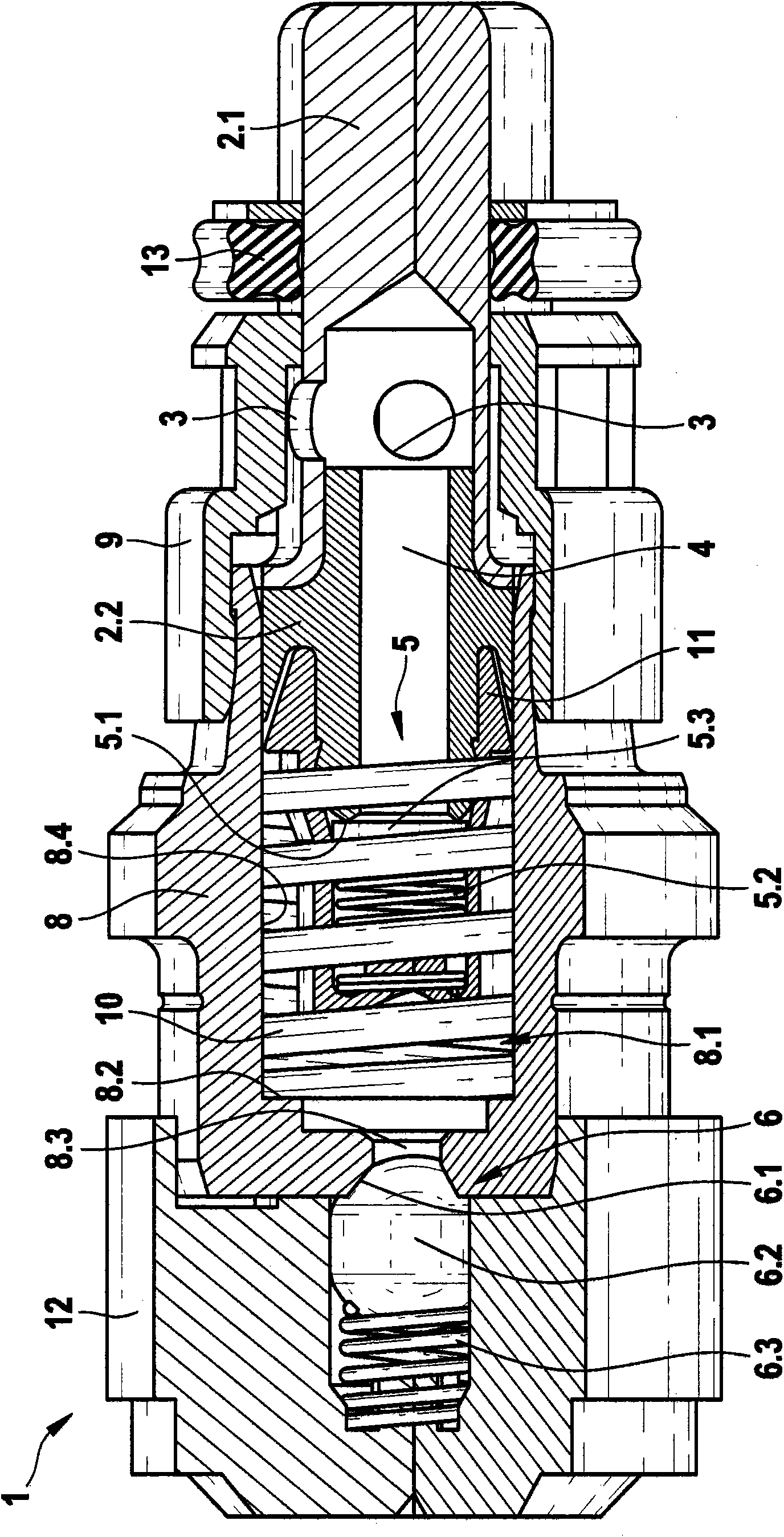

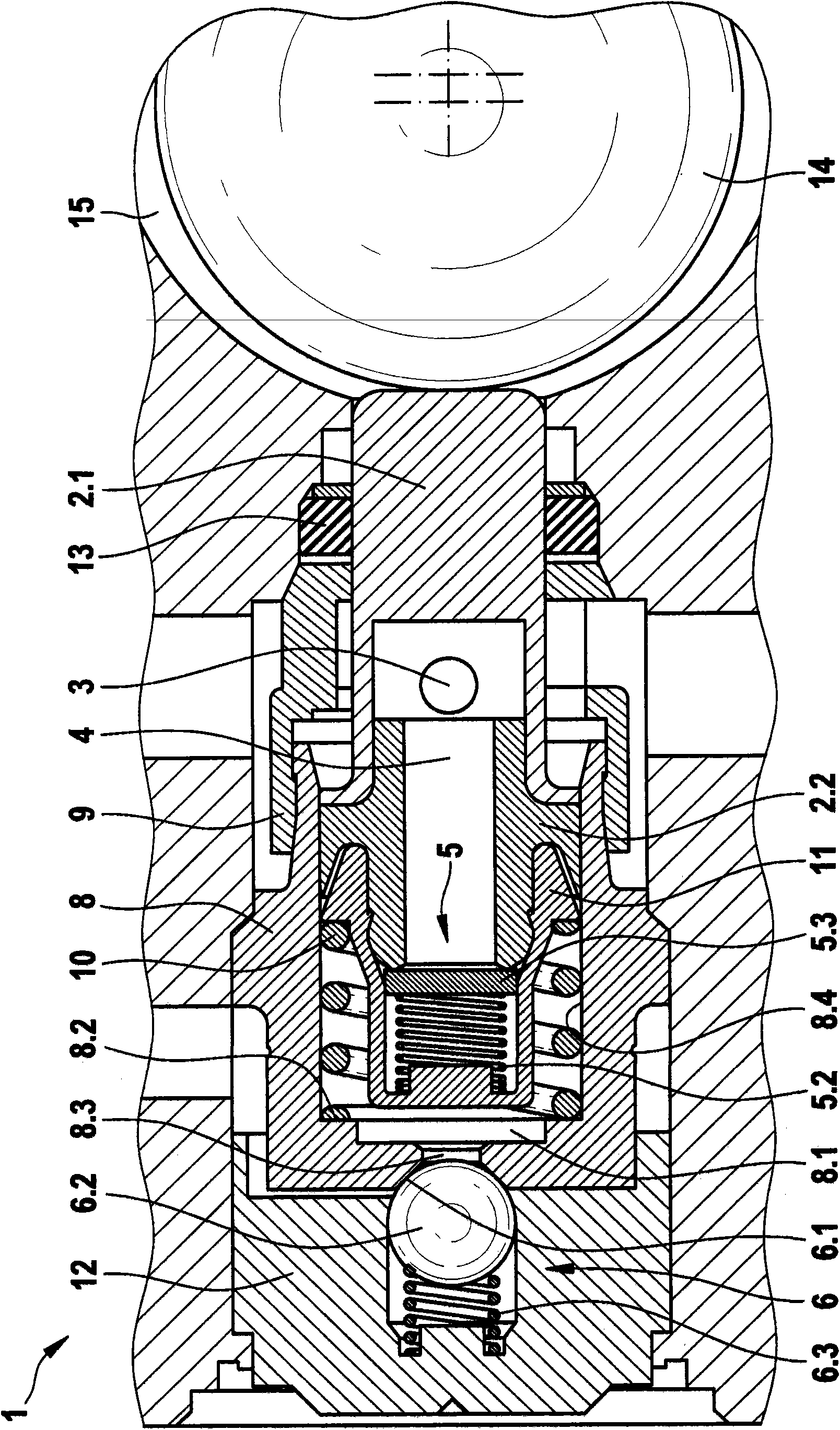

[0016] The piston pump according to the invention, which can be used as a return pump in a vehicle brake system, essentially comprises the same components as the conventional piston pump 1 described with reference to FIGS. 1 to 3 . Therefore, in order to avoid repetition, only the main differences of the piston pump according to the invention from the conventional piston pump 1 according to FIGS. 1 to 3 will be described in detail here. Unlike the conventional piston pump 1 according to FIGS. 1 to 3, the piston pump according to the invention comprises a modified inlet valve in combination with a modified piston assembly.

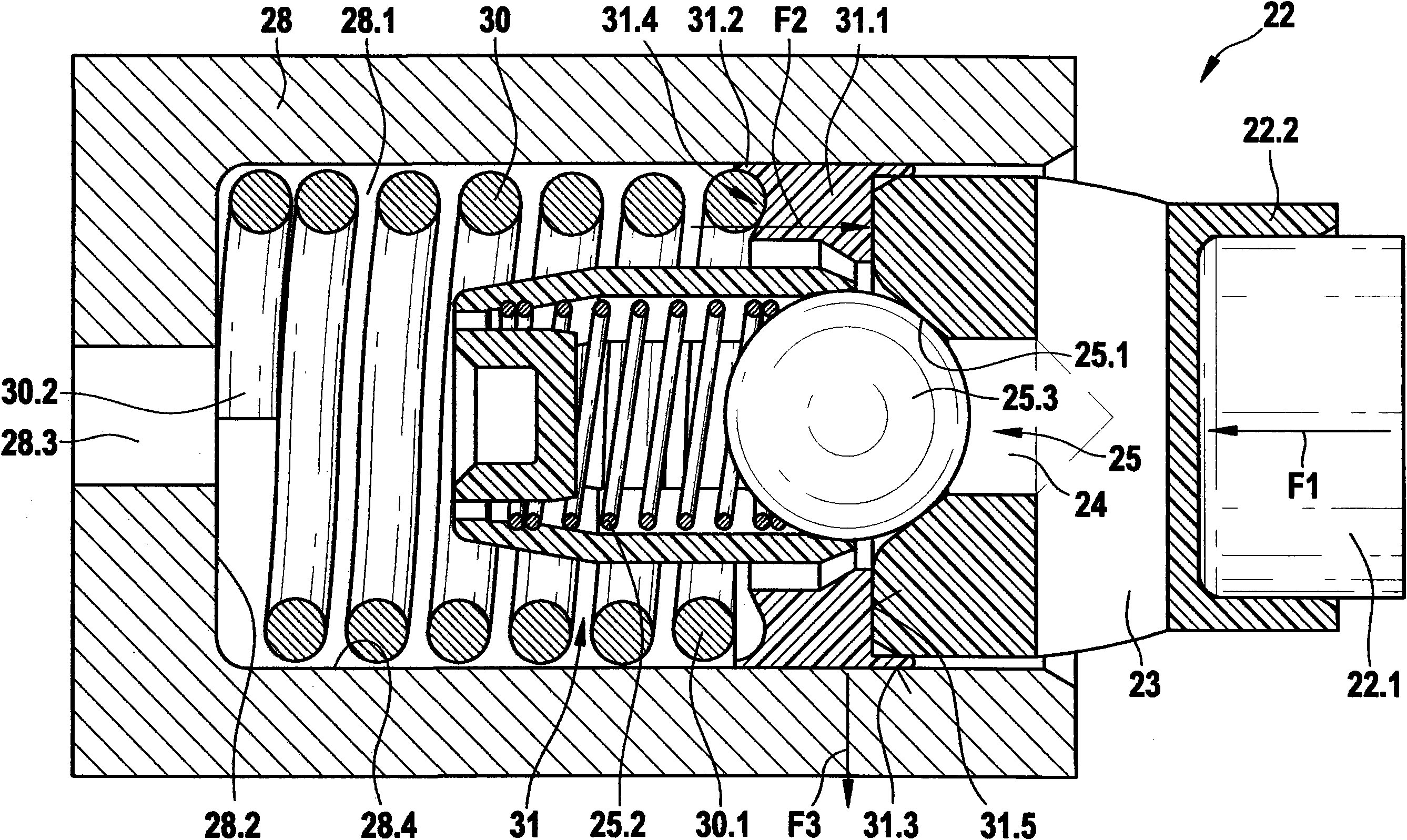

[0017] As shown in FIG. 4, similar to the conventional piston pump 1, the inlet valve 25 of the piston pump according to the invention comprises a cage 31 and a corresponding inlet valve seat 25.1, in which the inlet valve spring 25.2 and for example An inlet valve seal 25.3 consisting of a sealing ball, an inlet valve seat 25.1 is arranged on the second pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com