a glass oven

An oven and glass technology, applied in the field of electric ovens, can solve the problems of unreasonable structural design, inconvenient cleaning, unsanitary, etc., and achieve the effects of being beneficial to uniform heating, easy cleaning, and good power saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

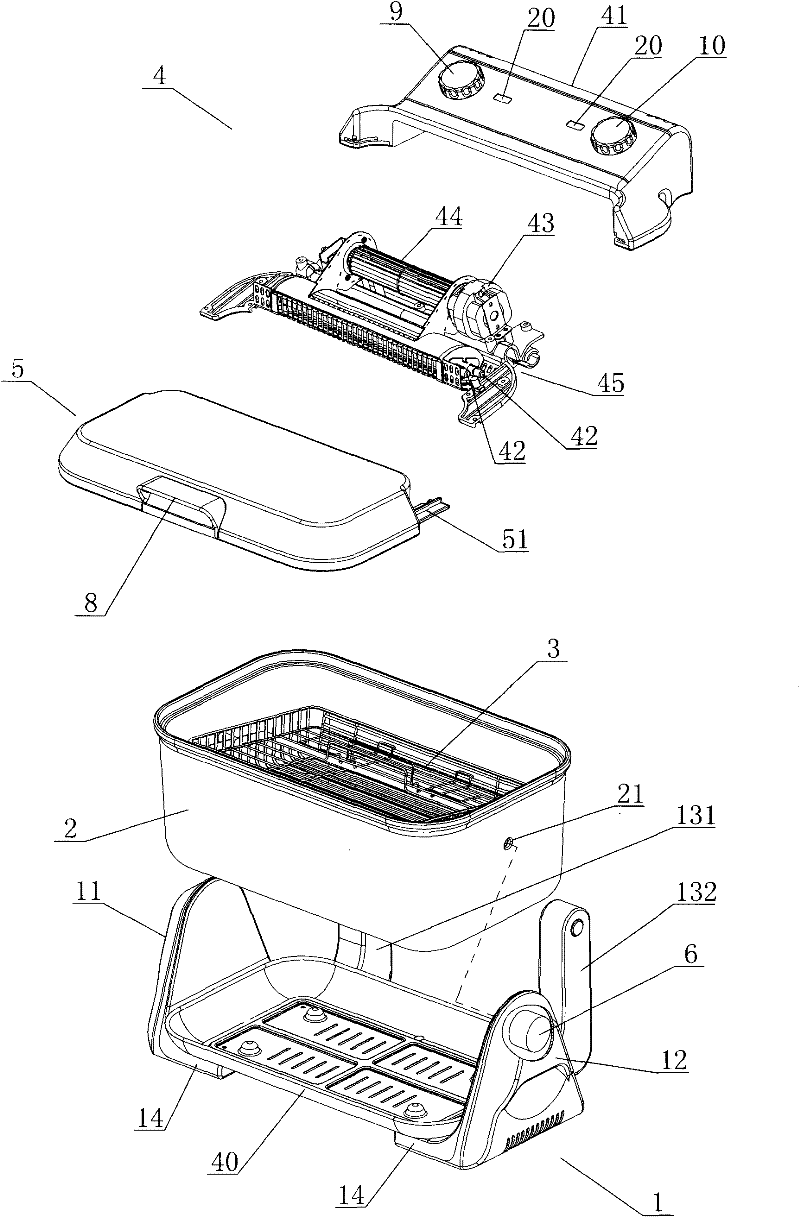

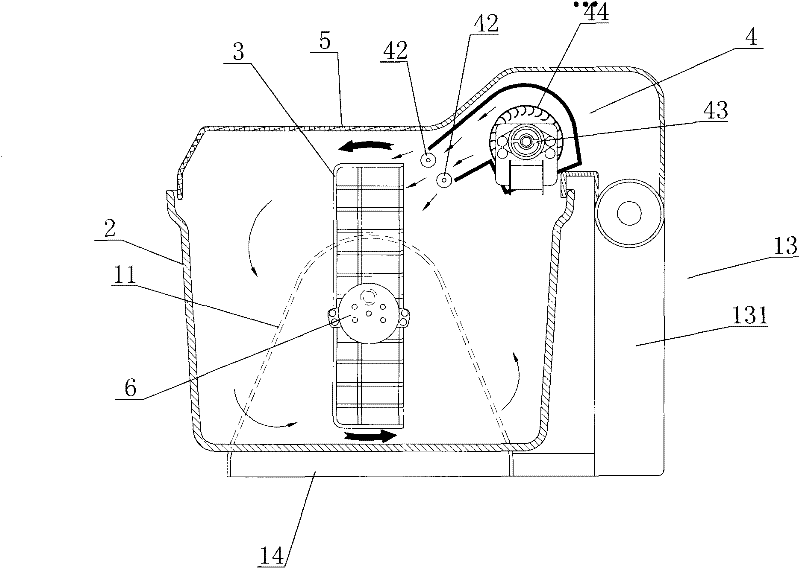

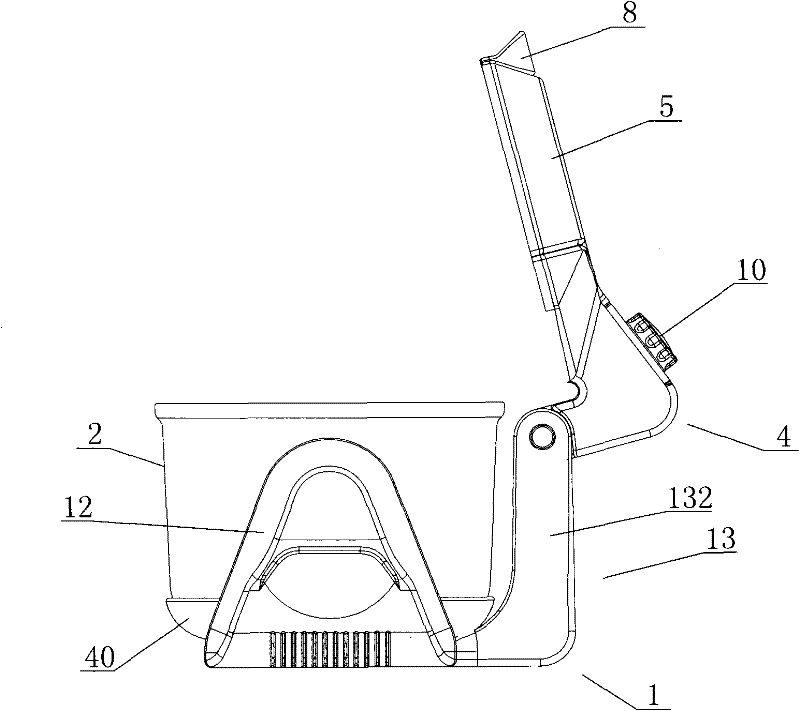

[0021] Such as figure 1 and figure 2 As shown, a glass oven according to the present invention includes a base 1, a glass container 2, a grill 3, a light wave heating device 4 capable of blowing out hot air, and a container cover 5 that can be placed on the glass container 2, wherein the base 1 is made into a cavity base for accommodating the glass container 2, and one side thereof is provided with a synchronous motor 6 for driving the grill 3 to rotate. The glass container 2 is detachably assembled in the base 1, and the glass container 2 and the base 1 are a kind of assembly structure without any fixed mechanical connection structure, so that the glass container 2 The base 1 can be put in or taken out conveniently. Moreover, the glass container 2 is generally made of high temperature resistant toughened glass material, so that it has the characteristics of high resistance and good durability. At the same time, the glass container 2 is generally made into a square structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com