Method for replacing jet rod of spraying machine and mechanism thereof

A sprayer and spray boom technology, which is applied in the direction of spraying devices, can solve the problems of low spraying efficiency, low use efficiency, and poor penetration, and achieve the effects of reducing drift and pollution, improving spraying efficiency, and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

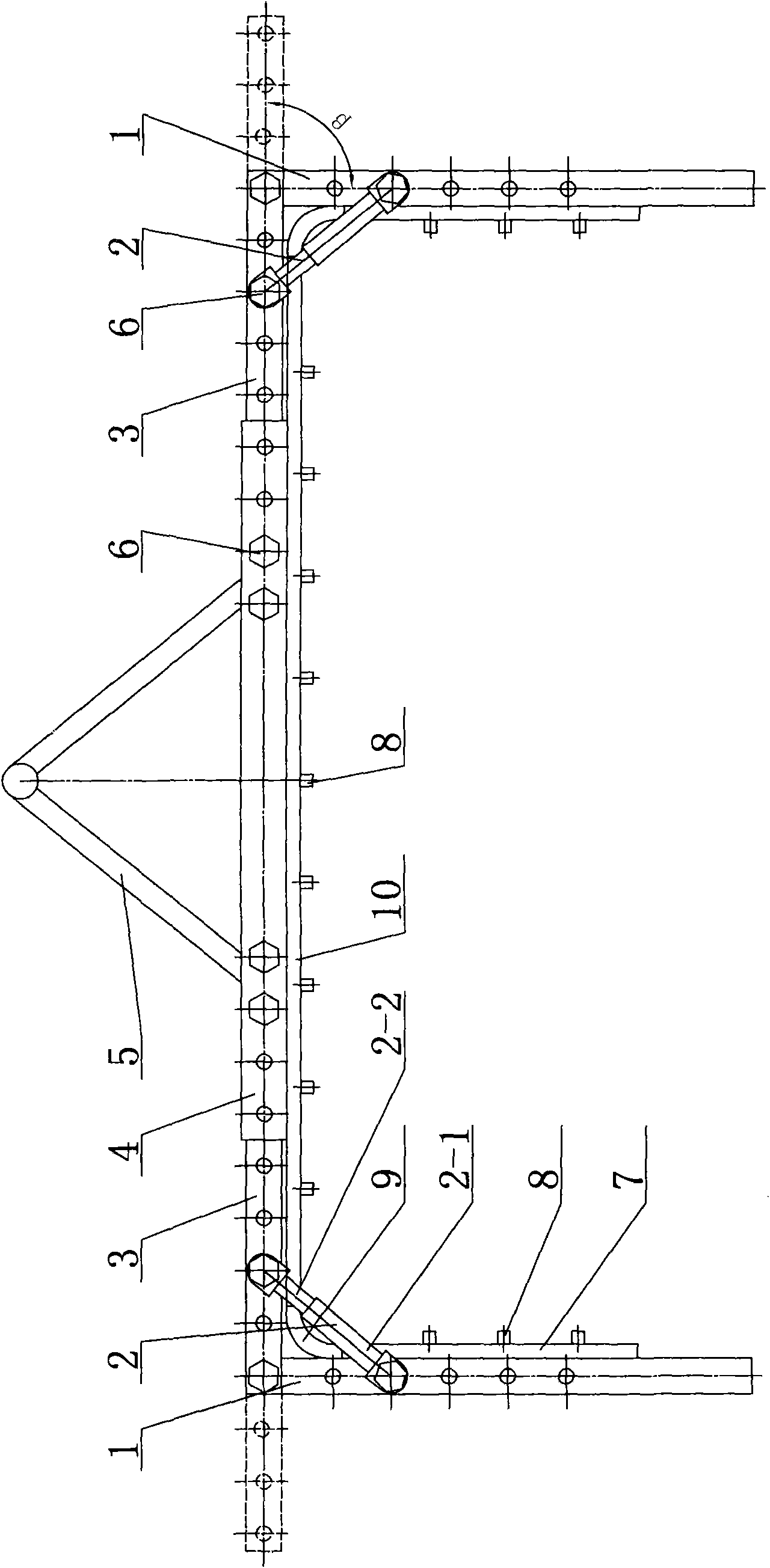

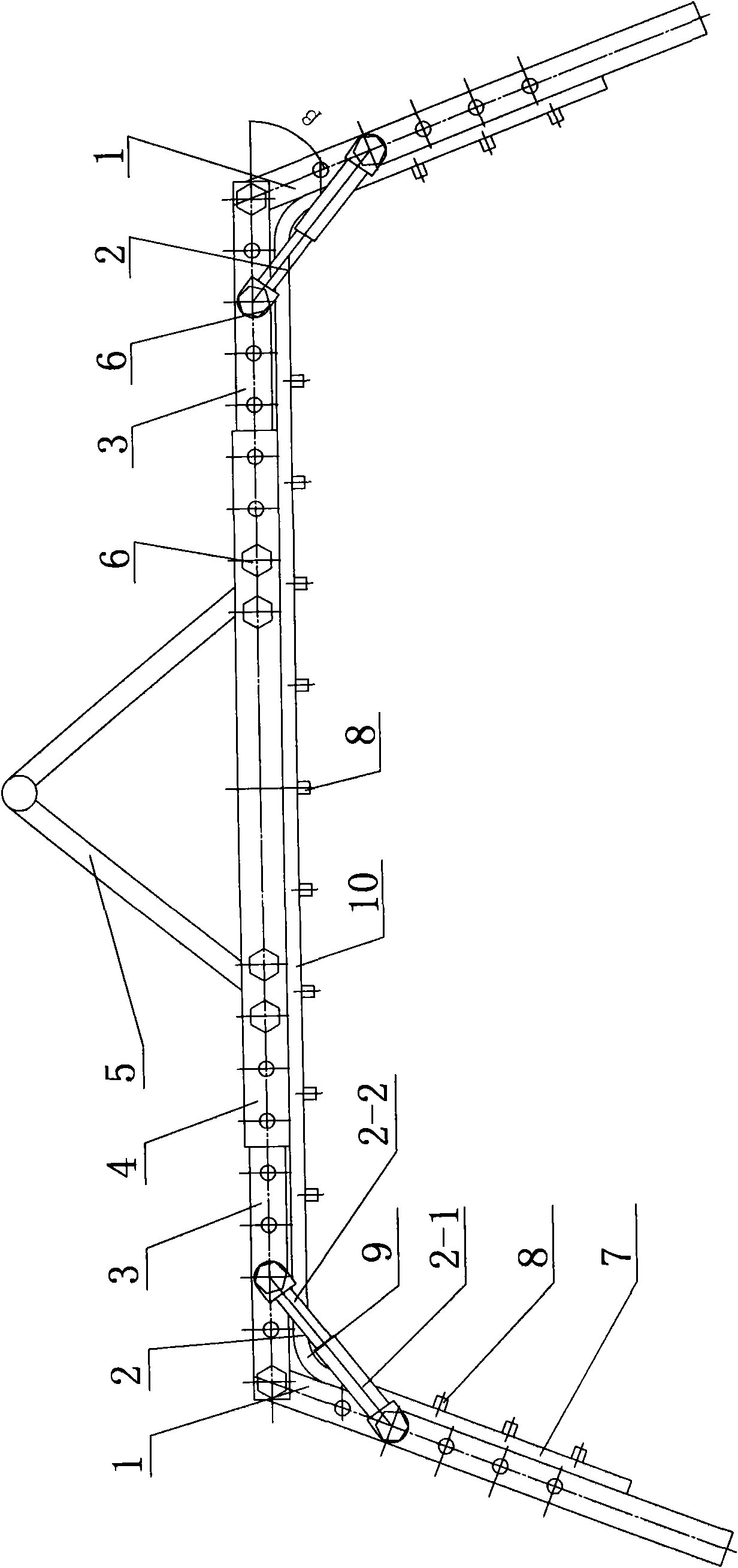

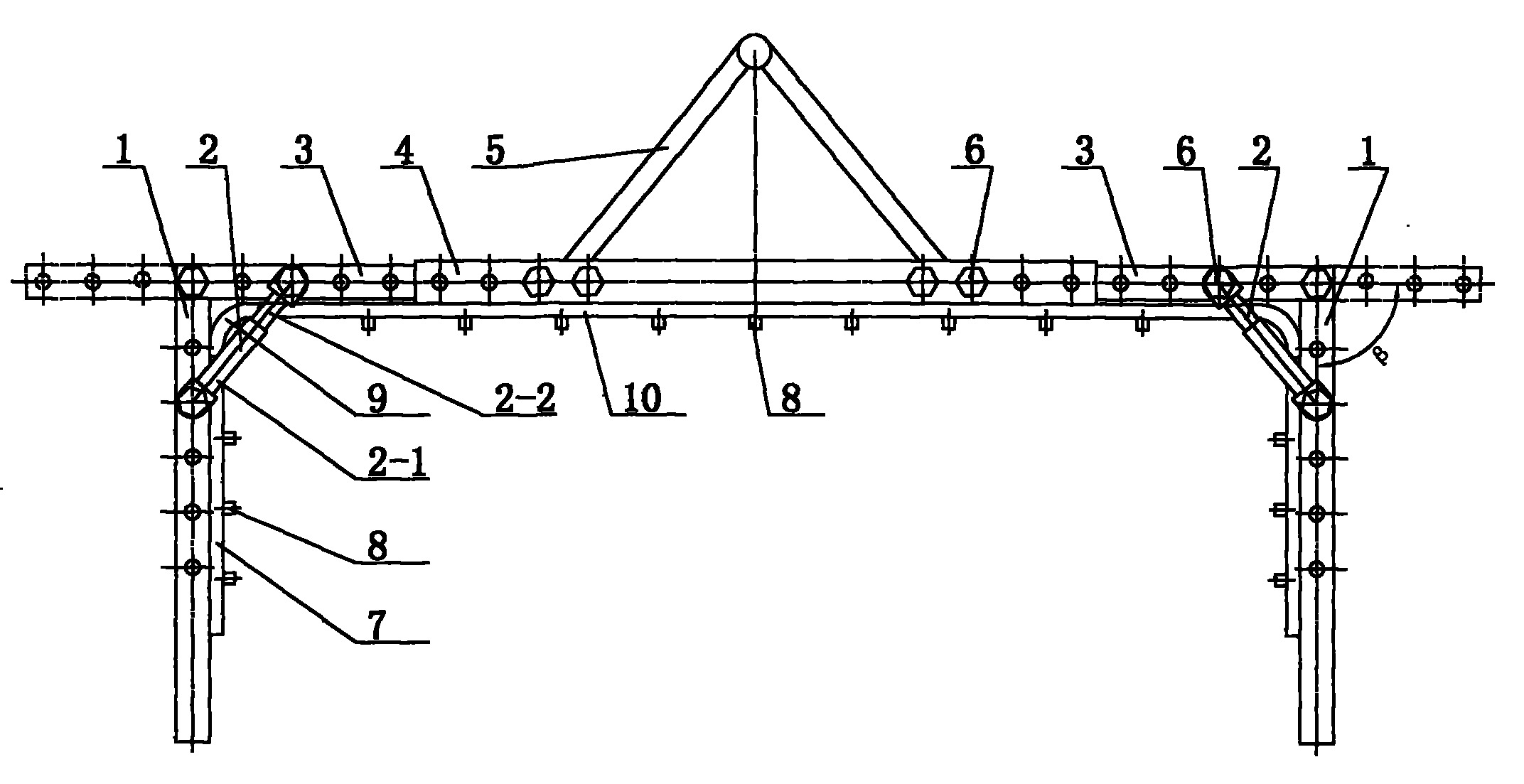

[0015] See figure 1 , 2 As shown, the conversion mechanism of the sprayer boom of the present invention includes a boom and a spray pipe, and the boom includes a fixed boom 4, two side booms 3, two vertical booms 1 and an adjustment support rod 2, fixed The spray bar 4 and the side spray bar 3 are provided with more than three corresponding adjustment holes, and the spray bars 3 on both sides that can move laterally are installed on both sides of the fixed spray bar 4 through fasteners 6, and the fasteners 6 are installed on the fixed One or both of the adjustment holes of the spray bar 4 and the side spray bar 3 are used to change the length of the horizontal spray bar. The total length of the fixed spray bar 4 and the side spray bar 3 of the present invention can be 800-2500mm, which can be adjusted according to the row spacing , such as 1000mm, 1200mm, 1300mm, 1500mm, 1800mm, etc., the upper part of the fixed spray bar 4 has a suspension frame 5, which is configured with d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com