Method for preparing atractylon

The technology of Atractylodes atractylodes and Atractylodes atractylodes, which is applied in the field of preparation of Atractylodes atractylodes, can solve the problems of cumbersome operation, unfavorable industrial scale-up, unfavorable industrialized operation, etc., and achieve the effects of less pollution, less energy consumption, and favorable large-scale production operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

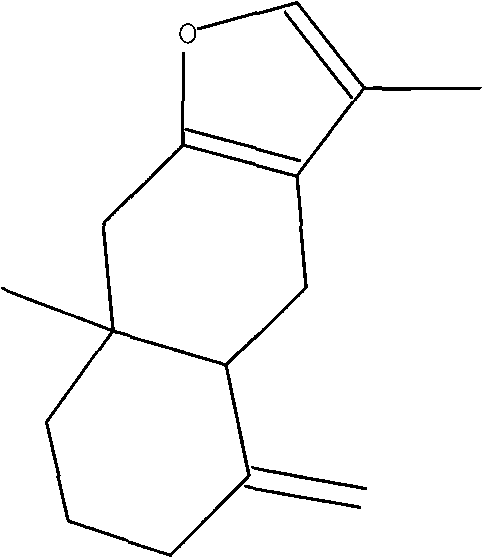

Image

Examples

Embodiment 1

[0015] Get 10Kg of dry rhizome of Atractylodes atractylodes, crush, add to CO 2 In the supercritical extractor, n-hexane is used as an entrainer, and the volume percentage of the entrainer in the total extraction solvent is 1%, the extraction pressure is 30MPa, the temperature is 40°C, and CO 2 The flow rate is 10L / min, the extraction time is 60min, and the extract is injected into a molecular still for two-stage molecular distillation. The evaporation surface temperature of the first stage distillation is 60°C, the pressure is 100Pa, the distillation time is 40min, and the distillate is collected. Carry out the second-stage distillation, the temperature of the evaporation surface is 30°C, the pressure is 60Pa, distill for 40min, collect the distillate, add acetone, refrigerate and crystallize, separate and crystallize, wash and dry to obtain 22.5g of atractylone, which is detected by HPLC. was 98.3%.

Embodiment 2

[0017] Get 10Kg of dry rhizome of Atractylodes atractylodes, crush, add to CO 2 In the supercritical extractor, n-hexane is used as an entrainer, and the volume percentage of the entrainer in the total extraction solvent is 4%, the extraction pressure is 60MPa, the temperature is 60°C, and the CO 2 The flow rate is 30L / min, the extraction time is 120min, and the extract is injected into a molecular still for two-stage molecular distillation. The evaporation surface temperature of the first stage distillation is 90°C, the pressure is 150Pa, the distillation time is 80min, and the distillate is collected. Carry out the second-stage distillation, the temperature of the evaporation surface is 50°C, the pressure is 80Pa, distill for 80min, collect the distillate, add acetone, refrigerate and crystallize, separate and crystallize, wash and dry to obtain 25.5g of atractylone, which is detected by HPLC. was 97.7%.

Embodiment 3

[0019] Get 10Kg of dry rhizome of Atractylodes atractylodes, crush, add to CO 2 In the supercritical extractor, n-hexane is used as an entrainer, and the volume percentage of the entrainer in the total extraction solvent is 3%, the extraction pressure is 50MPa, the temperature is 50°C, and the CO 2 The flow rate is 20L / min, the extraction time is 80min, and the extract is injected into a molecular still for two-stage molecular distillation. The evaporation surface temperature of the first stage distillation is 80°C, the pressure is 120Pa, the distillation time is 60min, and the distillate is collected. Carry out the second-stage distillation, the temperature of the evaporation surface is 40°C, the pressure is 70Pa, distill for 60min, collect the distillate, add acetone, refrigerate and crystallize, separate and crystallize, wash and dry to obtain 23.8g of atractylone, which is detected by HPLC. was 98.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com