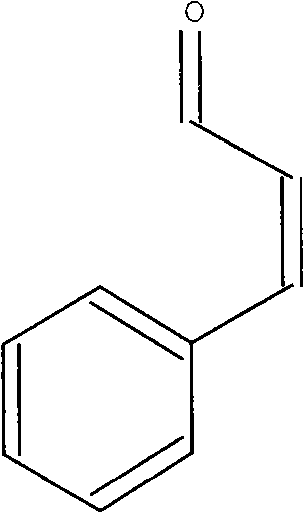

Preparation method of cinnamic aldehyde

A technology of cinnamaldehyde and cinnamon bark is applied in the field of preparation of cinnamaldehyde, and can solve the problems of serious pollution, unfavorable large-scale production operations, low cinnamaldehyde content and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Get 10Kg of cinnamon bark fine powder, add to CO 2 In the supercritical extractor, dichloromethane is used as an entrainer, and the volume percentage of the entrainer in the total extraction solvent is 2%, the extraction pressure is 10MPa, the temperature is 30°C, and the CO 2 The flow rate was 1ml / g crude drug / min, the extraction time was 80min, and the extract was obtained, which was dehydrated by adding anhydrous sodium sulfate, filtered, recovered methylene chloride and dried to obtain 8.3g of cinnamaldehyde, which was detected by HPLC with a purity of 98.9%.

Embodiment 2

[0020] Get 10Kg of cinnamon bark fine powder, add to CO 2 In the supercritical extractor, dichloromethane is used as an entrainer, and the volume percentage of the entrainer in the total extraction solvent is 6%, the extraction pressure is 40MPa, the temperature is 60°C, and the CO 2 The flow rate was 5ml / g crude drug / min, the extraction time was 200min, and the extract was obtained, which was dehydrated by adding anhydrous sodium sulfate, filtered, and the dichloromethane was recovered and dried to obtain 11.3g of cinnamaldehyde, which was detected by HPLC with a purity of 98.3%.

Embodiment 3

[0022] Get 10Kg of cinnamon bark fine powder, add to CO 2 In the supercritical extractor, dichloromethane is used as an entrainer, and the volume percentage of the entrainer in the total extraction solvent is 4%, the extraction pressure is 20MPa, the temperature is 50°C, and the CO 2 The flow rate was 2ml / g crude drug / min, the extraction time was 100min, and the extract was obtained, which was dehydrated by adding anhydrous sodium sulfate, filtered, and the dichloromethane was recovered and dried to obtain 13.0g of cinnamic aldehyde, which was detected by HPLC with a purity of 99.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com