Dipping material for capacitor of energy-saving lamp

A technology for capacitors and impregnating materials, which is applied in the direction of drying/impregnating machines, etc., which can solve the problems affecting the reliability and service life of capacitors, the capacitors are prone to bubbles, and poor tightness, so as to achieve good sealing of appearance, avoid whitening phenomenon, Effect of improving insulation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Capacitor impregnating materials for energy-saving lamps, including epoxy resin, with epoxy resin as the base of mass percentage, and the rest of the ingredients are as follows:

[0015] 5300 defoamer 0.1~0.15%,

[0016] 6500 defoamer 0.1~0.15%,

[0017] 351 chrome glass powder 4~6%,

[0018] Silica powder 60-70%,

[0019] Silica 2-3%,

[0020] Curing agent 20-25%, the curing agent is fatty polyamine, polyethylene polyamine or trimethylhexamethylenediamine;

[0021] Styrene 20-30%.

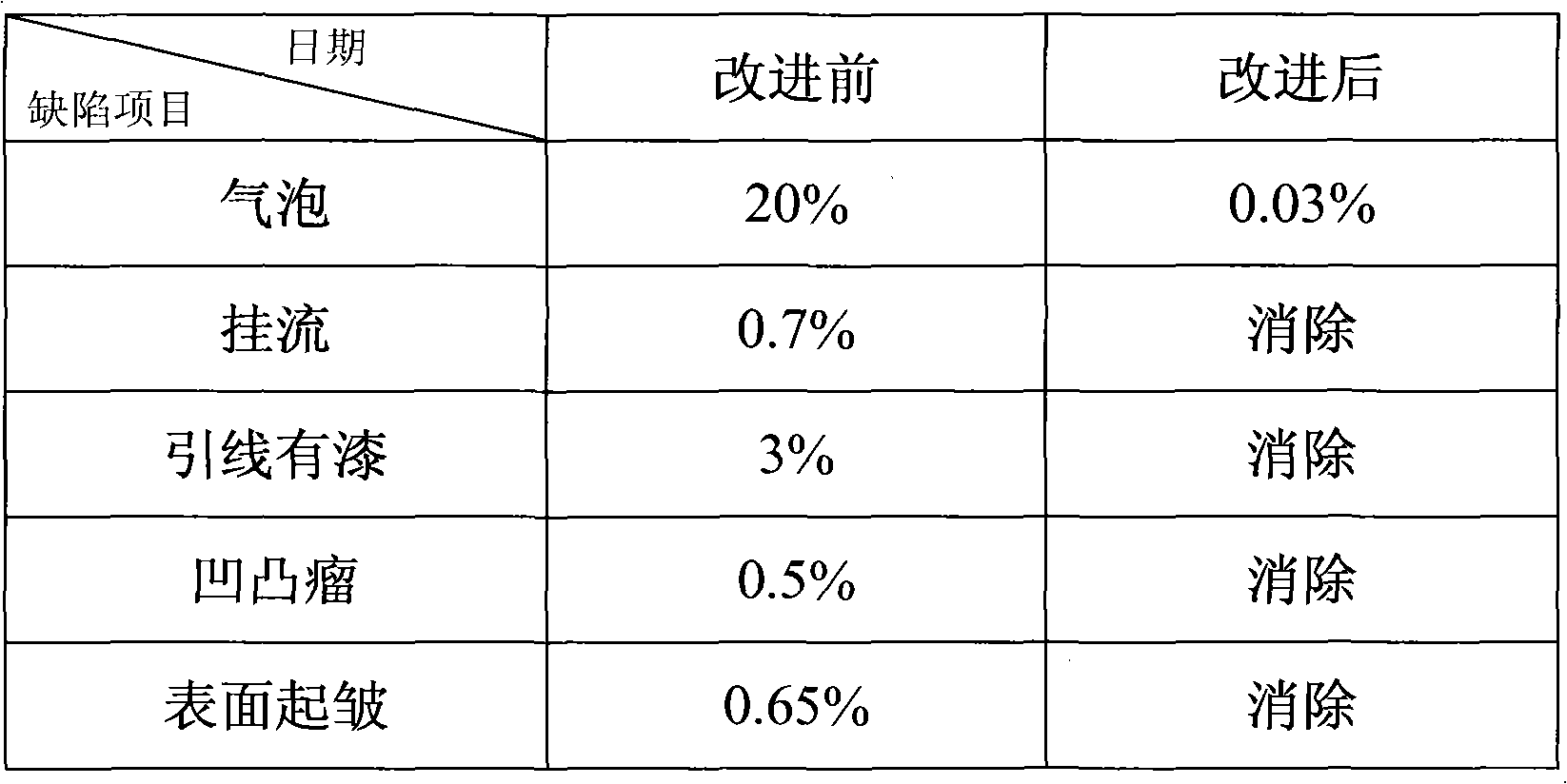

[0022] Using the above impregnating materials for impregnation treatment, the effect of improving the appearance of the product is obvious (the following percentages are the probability of defects for each certain number of batches, taking 10,000 pieces / batch as an example):

[0023]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com