Method for preparing monophosphonate and biphosphonate mixed fire retardant

A flame retardant and phosphonate technology, which is applied in the field of preparation of single and double mixed phosphonate flame retardants, can solve the problems of harsh reaction conditions, rare raw materials, and difficult control, and achieves no emission in the production process and product utilization. The effect of high rate and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

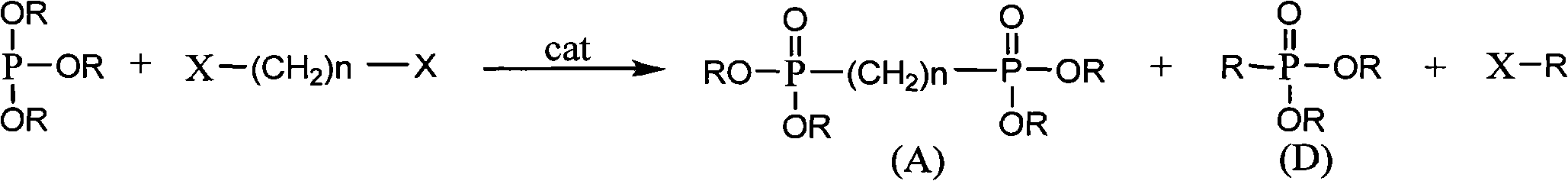

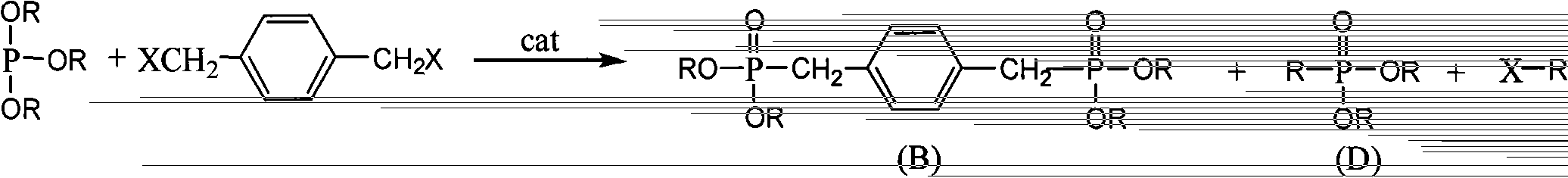

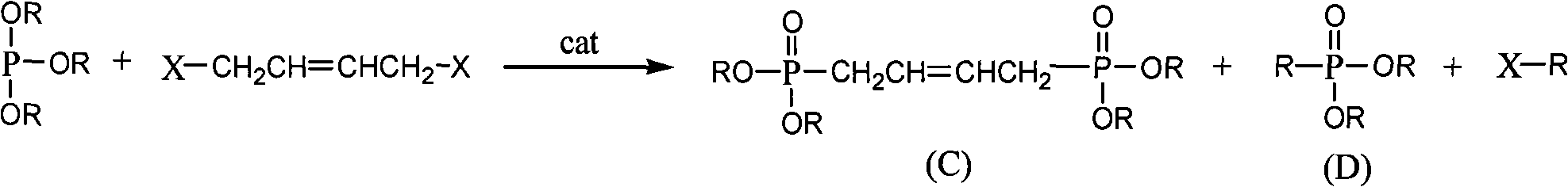

Method used

Image

Examples

Embodiment 1

[0054] Add trimethyl phosphite (P(OCH 3 ) 3 )37.2g, 1,2-dibromoethane (BrCH 2 CH 2 Br) 18.8g, catalyst I 20.25g. Turn on the condensed water, heat and stir, and start to reflux when the temperature rises to about 120°C, continue heating, the temperature gradually rises to 170°C, and the degree of reflux decreases significantly. Continue the reaction, and when there is basically no reflux, keep the temperature at 180-190°C for 1 hour. Atmospheric distillation and suction filtration gave 34.7 g of a colorless and transparent product with a total yield of 93.8%, among which the yield of tetramethyl 1,2-ethylenebisphosphonate was 55.5%.

Embodiment 2

[0056] Add trimethyl phosphite (P(OCH 3 ) 3 )37.2g, 1,2-dibromoethane (BrCH 2 CH 2 Br) 18.8g, catalyst NaI 0.25g. Turn on the condensed water, heat and stir, and start to reflux when the temperature rises to about 120°C, continue heating, the temperature gradually rises to 170°C, and the degree of reflux decreases significantly. Continue the reaction, and when there is basically no reflux, keep the temperature at 180-190°C for 1 hour. Atmospheric distillation and suction filtration gave 34.2 g of a colorless and transparent product with a total yield of 92.4%, among which the yield of tetramethyl 1,2-ethylenebisphosphonate was 63.7%.

Embodiment 3

[0058] Add trimethyl phosphite (P(OCH 3 ) 3 )37.2g, 1,2-dibromoethane (BrCH 2 CH 2 Br) 18.8g, catalyst (CH 3 ) 4NI 0.25g. Turn on the condensed water, heat and stir, and start to reflux when the temperature rises to about 120°C, continue heating, the temperature gradually rises to 170°C, and the degree of reflux decreases significantly. Continue the reaction, and when there is basically no reflux, keep the temperature at 180-190°C for 1 hour. Atmospheric distillation yielded 35.5 g of a colorless and transparent product with a total yield of 95.9%, among which the yield of tetramethyl 1,2-ethylenebisphosphonate was 86.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com