Object-oriented cooling device based on pulse tube refrigerator

A pulse tube refrigerator, an object-oriented technology, applied in the field of refrigeration and low temperature, can solve the problems of insufficient heat transfer capacity, limited cooling capacity of refrigerators, large heat transfer temperature difference, etc., to simplify the heat transfer process, improve cooling efficiency, reduce The effect of small heat transfer temperature differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

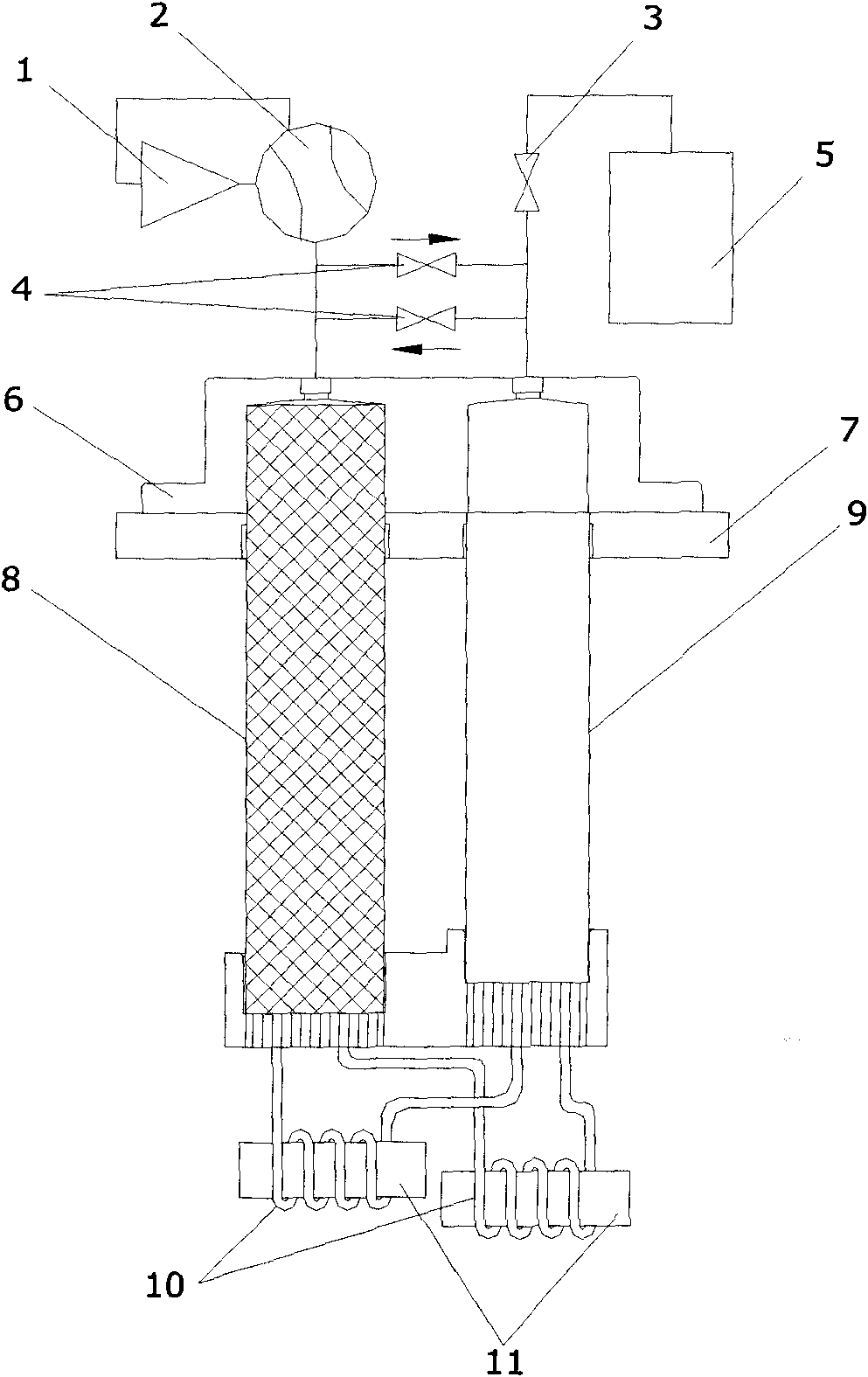

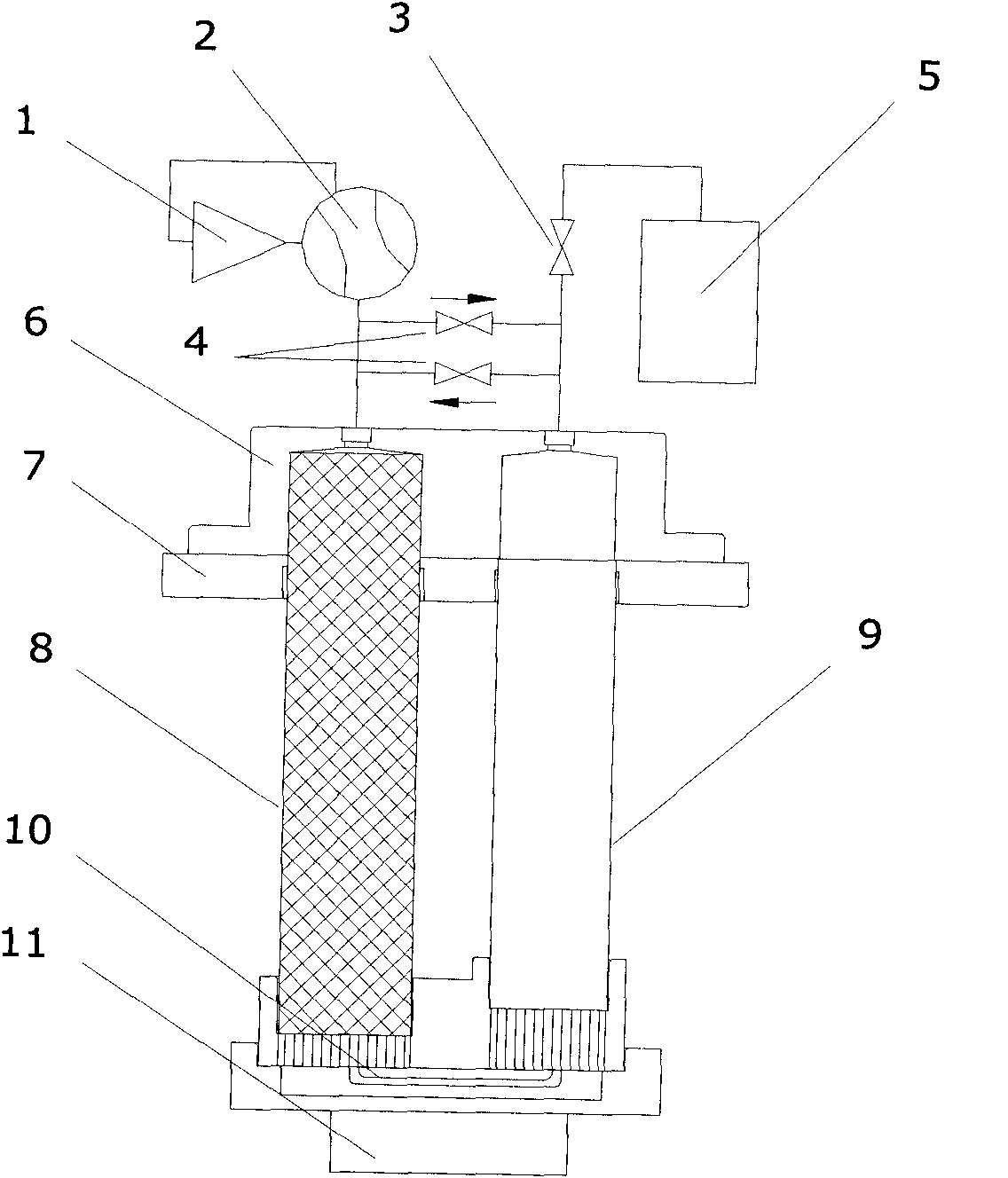

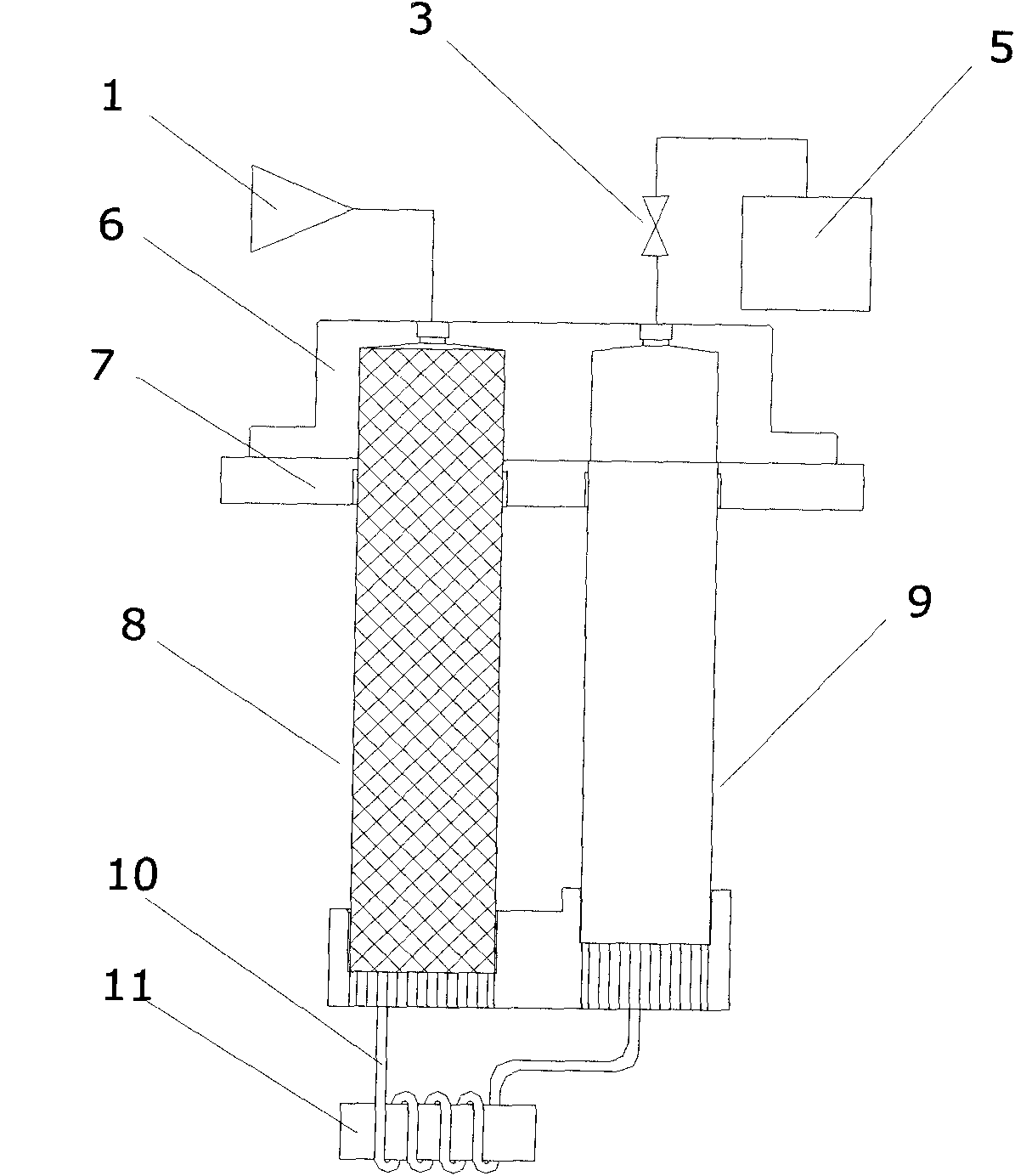

[0019] As shown in the figure, the object-oriented cooling device based on the pulse tube refrigerator includes a compressor 1, a rotary valve 2, an orifice valve 3, a two-way inlet valve 4, an air reservoir 5, a cover 6, a flange 7, and a regenerator 8. The pulse tube 9, the cold head connection coil 10, the cooled device 11, the compressor 1 is connected with the rotary valve 2, and the rotary valve 2 is respectively connected with the hot end of the regenerator 8 and one end of the two-way intake valve 4, The gas storage 5 is respectively connected to the hot end of the pulse tube 9 and the other end of the two-way intake valve 4 through the small hole valve 3 , and the regenerator 8 and the cold end of the pulse tube 9 are connected by a cold head connection coil 10 .

[0020] The pulse tube refrigerator is a GM type pulse tube refrigerator or a Stirling type pulse tube refrigerator. The drive mode of the compressor 1 is electric drive or heat energy drive. The cold head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com