Device for automatically detecting high pressure resistance and electric function of electronic component product

An electronic component and automatic detection technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve problems such as time-consuming and labor-intensive efficiency, manual detection and judgment of great stability, etc., to reduce operating costs or equipment costs, and solve product problems. Effects of quality misjudgment and high variability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The invention will be further described in detail below in conjunction with the embodiments of the accompanying drawings.

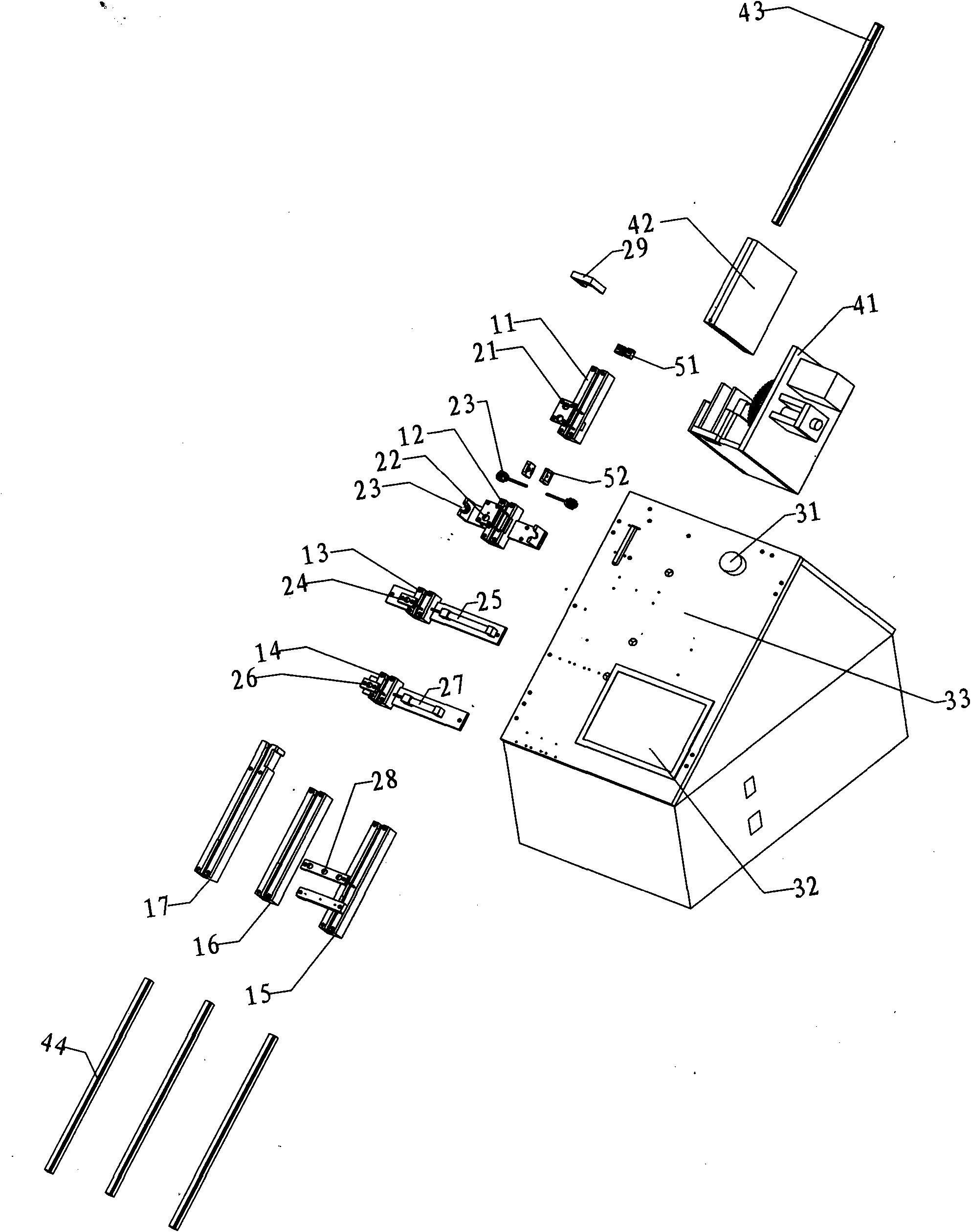

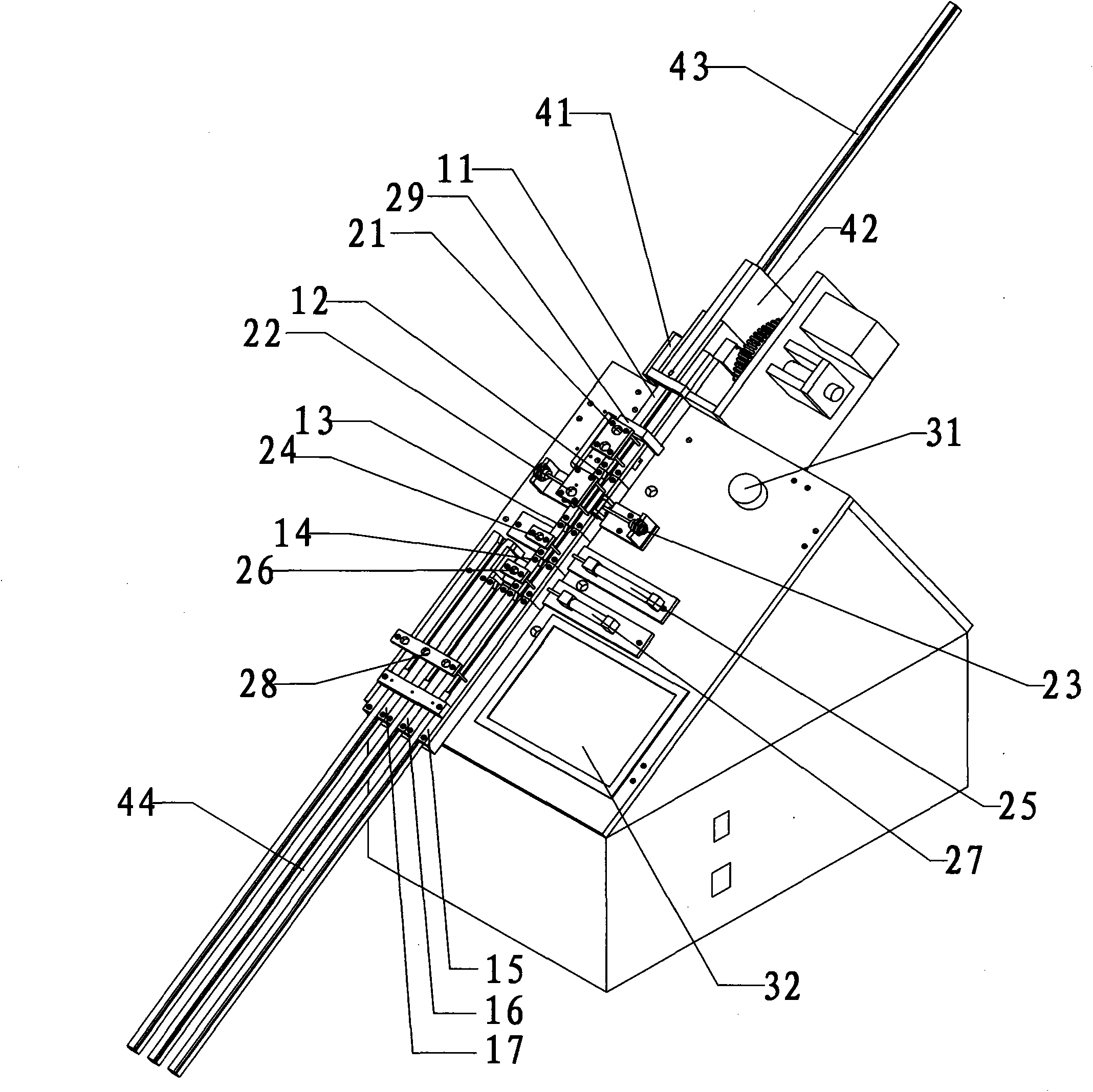

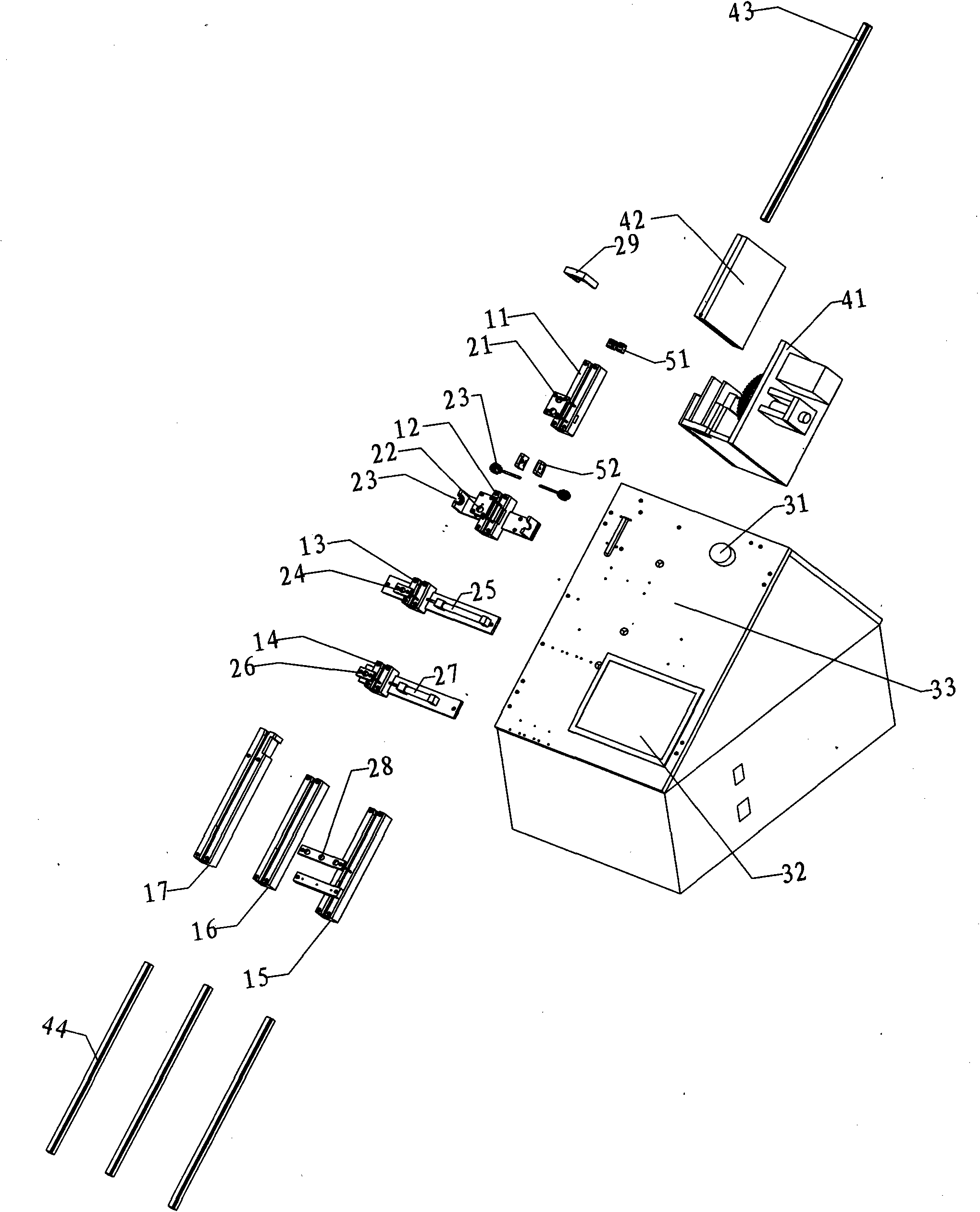

[0041] Such as figure 1 and figure 2 shows, a device for automatically testing the high-voltage resistance and electrical functions of electronic component products, including: feeding mechanism, high-voltage testing part, electrical The testing part and the defective product automatic sorting part are equipped with a high-voltage tester, an electrical tester, and a central control system connected to control the above-mentioned parts inside the workbench;

[0042]——The feeding mechanism is a feed pipe 43, or the feed pipe 43 can be inserted into the magazine 42 and then the magazine is loaded into the base of the magazine 41;

[0043] ——The high-voltage test part includes: a high-voltage test slideway made of non-conductive material, and a high-voltage test seat is set in the high-voltage test slideway. The high-voltage test seat is two metal b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com