Preparation method of 1,2,3-tri-O-acetyl-5-deoxidization-beta-D-ribose

An acetyl and ribose technology, applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of many by-products, low purity, energy consumption, etc., and achieve simple and moderate conditions and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

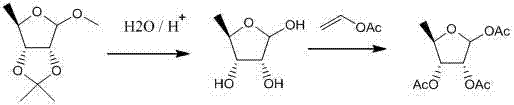

[0025] The method of the present embodiment has the following steps:

[0026] ①Add 50.3g of 2,3-O-isopropylidene-5-deoxy-D-furanoside to 300mL of 1wt% hydrochloric acid solution, and 2,3-O-isopropylidene Propylene-5-deoxy-D-furanoside undergoes a hydrolysis reaction of 5-deoxy-D-ribose for 4 hours, and TLC (thin layer chromatography) monitors until the raw material point disappears (dichloromethane:methanol=1:1), After reaction finishes, obtain the aqueous solution that contains 5-deoxy-D-ribose of 297.3g.

[0027] ② Add 303.0 g of acetylation reagent vinyl acetate to the aqueous solution containing 5-deoxy-D-ribose obtained in step ①, and generate 1,2,3-tri-O-acetyl at a temperature of 15°C to 25°C The acetylation reaction of base-5-deoxy-D-ribose was carried out for 3 hours. During the reaction, 5% NaOH solution was added dropwise to keep the pH at 10. An aqueous solution containing 1,2,3-tri-O-acetyl-5-deoxy-D-ribose was obtained.

[0028]③ After the acetylation reaction...

Embodiment 2)

[0033] The method of the present embodiment has the following steps:

[0034] ①Add 51.2g of 2,3-O-isopropylidene-5-deoxy-D-furanoside to 250mL of sulfuric acid solution with a concentration of 1wt%. Propylene-5-deoxy-D-methylfuranoside undergoes a hydrolysis reaction of 5-deoxy-D-ribose for 3 hours, and TLC monitors until the raw material point disappears (dichloromethane:methanol=1:1). After the reaction, the obtained 237.2 g of an aqueous solution containing 5-deoxy-D-ribose.

[0035] ② Add 242.2 g of acetylation reagent vinyl acetate to the aqueous solution containing 5-deoxy-D-ribose obtained in step ①, and generate 1,2,3-tri-O-acetyl at a temperature of 15°C to 25°C The acetylation reaction of base-5-deoxy-D-ribose was 4h, and the concentration of 10% Na was added dropwise during the reaction 3 PO 4 solution to maintain a pH of 10. An aqueous solution containing 1,2,3-tri-O-acetyl-5-deoxy-D-ribose was obtained.

[0036] ③ After the acetylation reaction, carry out pos...

Embodiment 3)

[0041] The method of the present embodiment has the following steps:

[0042] ①Add 50.4g of 2,3-O-isopropylidene-5-deoxy-D-furanoside to 250mL of sulfuric acid solution with a concentration of 1wt%. Propylene-5-deoxy-D-methylfuranoside undergoes a hydrolysis reaction of 5-deoxy-D-ribose for 3 hours, and TLC monitors until the raw material point disappears (dichloromethane:methanol=1:1). After the reaction, the obtained 230.3 g of an aqueous solution containing 5-deoxy-D-ribose.

[0043] ② Add 232.1 g of acetylation reagent isopropenyl acetate to the aqueous solution containing 5-deoxy-D-ribose obtained in step ①, and generate 1,2,3-tri-O- The acetylation reaction of acetyl-5-deoxy-D-ribose was 3h, and the concentration of 10% Na was added dropwise during the reaction 2 CO 3 solution to maintain a pH of 10. An aqueous solution containing 1,2,3-tri-O-acetyl-5-deoxy-D-ribose was obtained.

[0044] ③ After the acetylation reaction, carry out post-treatment to obtain the crude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com