Chameleon coating, use method thereof on colored coating steel plate and colored coating steel plate

A technology of chameleon and color coating, which is applied in the field of coatings to achieve the effects of improving anti-counterfeiting, prolonging service life and upgrading grades

Active Publication Date: 2010-09-08

CHANGSHU HUAYE STEEL STRIP

View PDF9 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In the known technology, there is no technical revelation about the rapid and continuous production of steel plates with coatings and high-temperature baking to make the surface have a chameleon effect. demand market

Method used

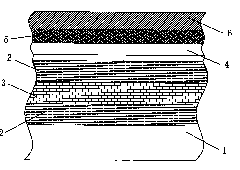

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0030] Following table is the formula that constitutes the chameleon paint of embodiment 1 of the present invention:

[0031]

[0032]

Embodiment 2

[0034] Following table is the formula of embodiment 2 of the present invention:

[0035]

Embodiment 3

[0037] The following table is the formula of embodiment 3 of the present invention:

[0038]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a chameleon coating comprising the following raw materials in parts by weight: 10-40 parts of matrix material, 1-20 parts of filling material, 1-25 parts of solvent, 3-20 parts of curing agent, 1-10 parts of pigment, 1-10 parts of assistant and 1-10 parts of angular heterochromous powder or comprising the following raw materials in parts by weight: 10-50 parts of matrix material, 1-20 parts of filling material, 1-25 parts of solvent, 2-10 parts of curing agent, 1-5 parts of pigment, 1-10 parts of assistant and 1-10 parts of optical interference powder. The invention also relates to the use method of the chameleon coating on a colored coating steel plate and a novel colored coating steel plate.

Description

technical field [0001] The invention belongs to the technical field of coatings, specifically relates to a chameleon coating, and also relates to a method for using the coating on a color-coated steel plate. The invention also discloses a color-coated steel plate. Background technique [0002] With the development of the economy and the improvement of people's living standards, people's pursuit of aesthetics is getting higher and higher. Therefore, products such as furniture and home appliances with a chameleon effect are more and more valued by people. [0003] Although the formation method of the angle-dependent effect is not unfamiliar to people, through the different distribution levels of the angle-dependent pigments, the color changes with the viewing angle caused by optical physical phenomena such as reflection, refraction and interference. In the field of anti-counterfeiting, since the color-dependent function of the color-dependent pigment cannot be easily reproduc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D163/00C09D167/00C09D127/06C09D133/00C09D127/16C09D175/04C09D5/29B05D5/06B05D7/26B44C5/04

Inventor 徐金刚王珏许秀飞吕敬九

Owner CHANGSHU HUAYE STEEL STRIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com