Municipal solid waste heat accumulating type gasification and melting incineration system

A technology of gasification and melting of municipal solid waste, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of heavy metals, high content of dioxins, high consumption of precious energy, etc., and achieve low content of dioxins, fully absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

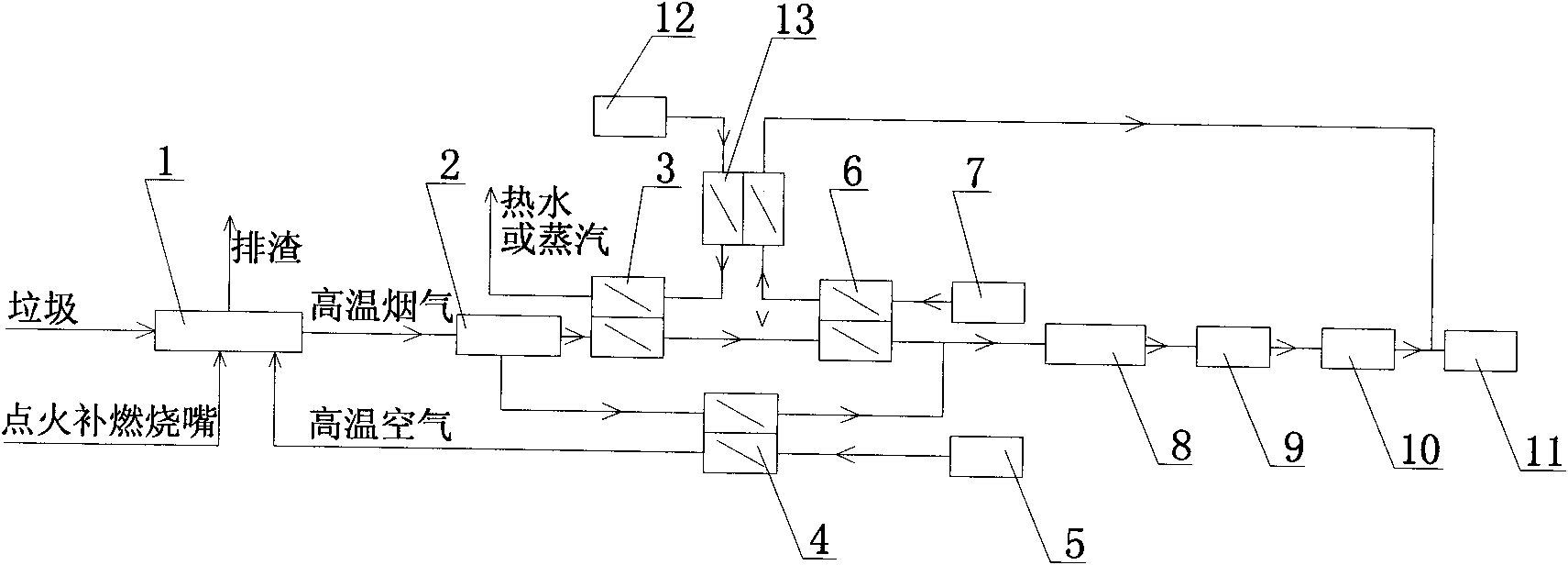

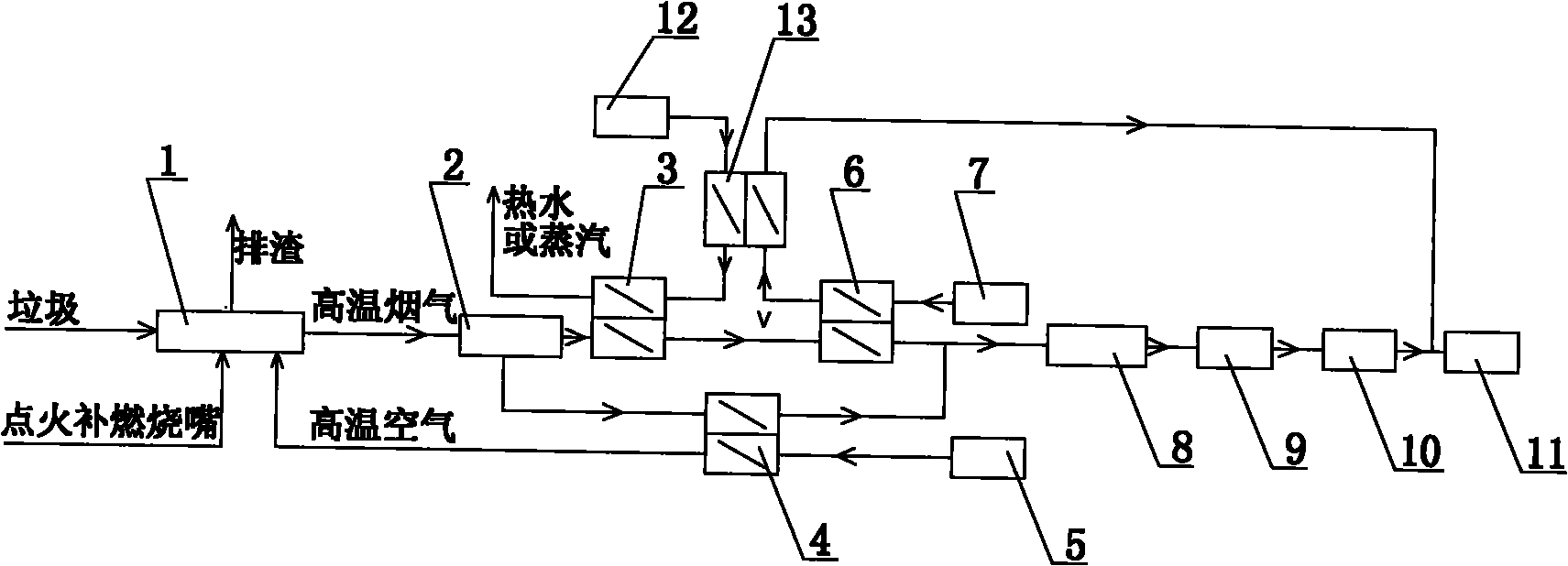

[0013] The municipal solid waste regenerative gasification melting incineration system of the present invention, its preferred embodiment is:

[0014] It includes a gasification melting incinerator, the gasification melting incinerator includes a high-temperature air inlet and a high-temperature flue gas outlet, and is characterized in that the high-temperature flue gas outlet is connected to the inlet of a high-temperature cyclone dust collector;

[0015] The outlet of the high-temperature cyclone dust collector is divided into two routes, one of which is connected to the flue gas side inlet of the first high-temperature air heat storage device, and the other is connected to the flue gas side inlet of the waste heat boiler, and the flue gas side outlet of the waste heat boiler is connected to the first Second, the flue gas side inlet connection of the high-temperature air heat storage device;

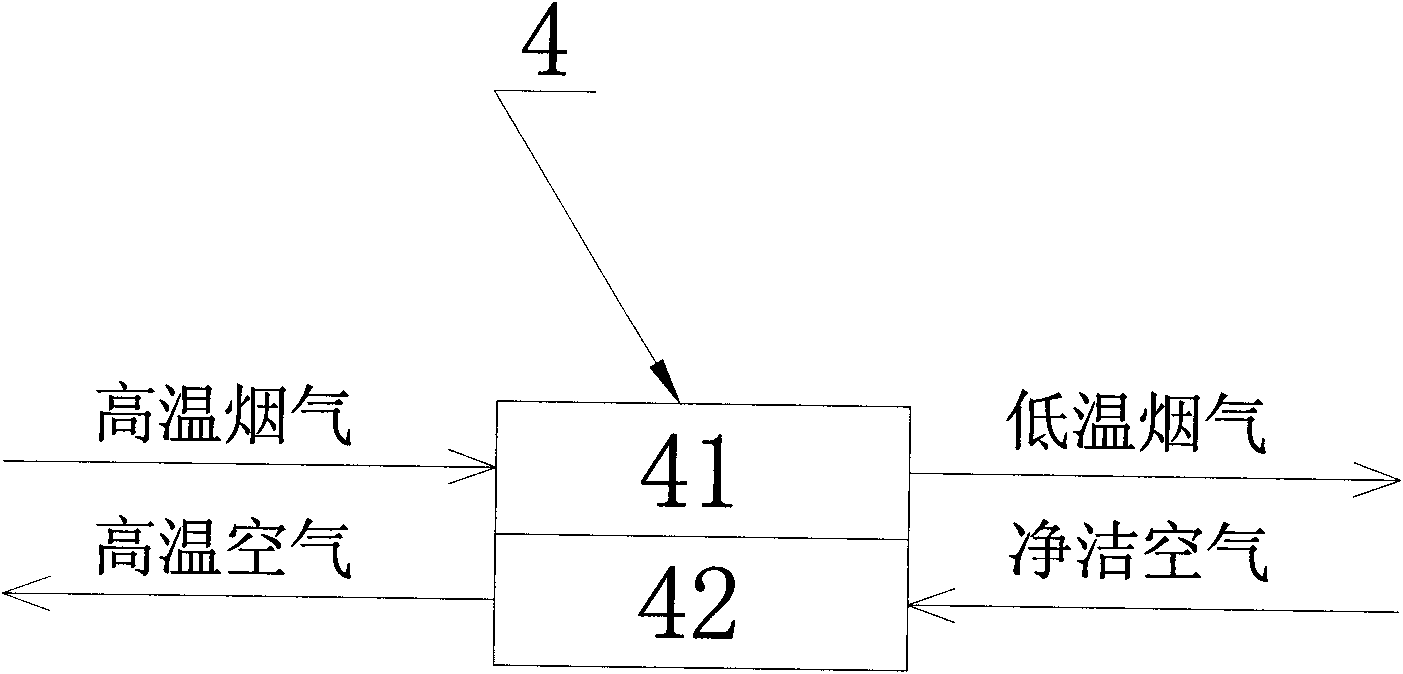

[0016] The flue gas side outlet of the second high temperature air heat storage de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com