Rim material compression device of sintering machine trolley

A technology of pressing device and machine trolley, which is applied in the field of metallurgy to achieve the effects of reducing air leakage rate, reducing cost, and exquisite structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

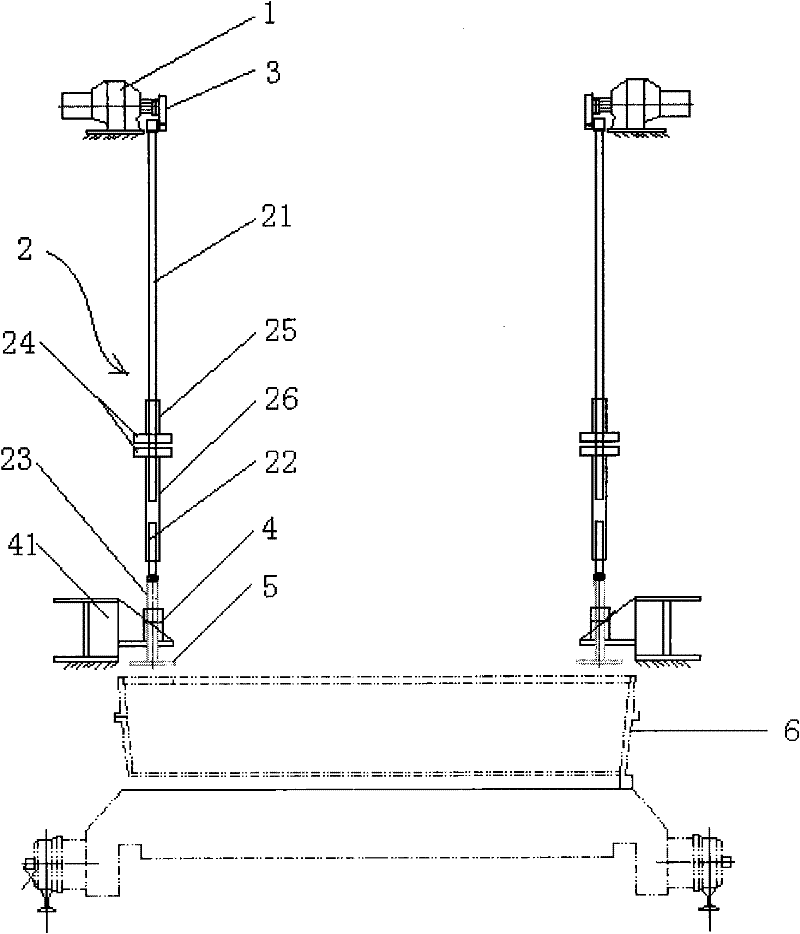

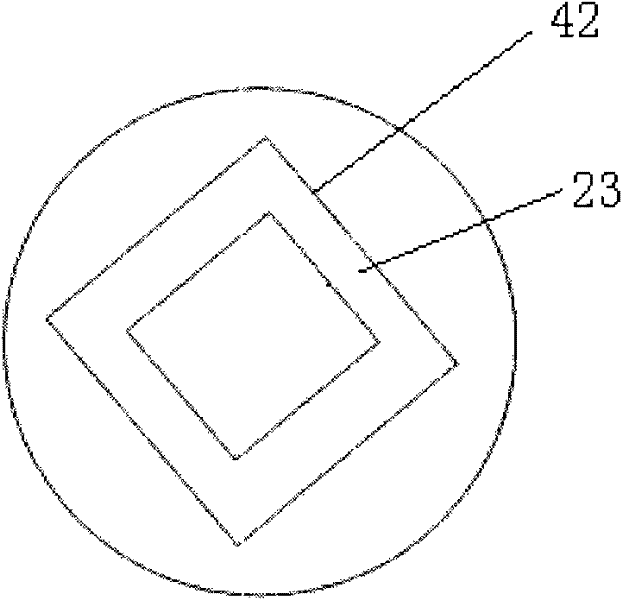

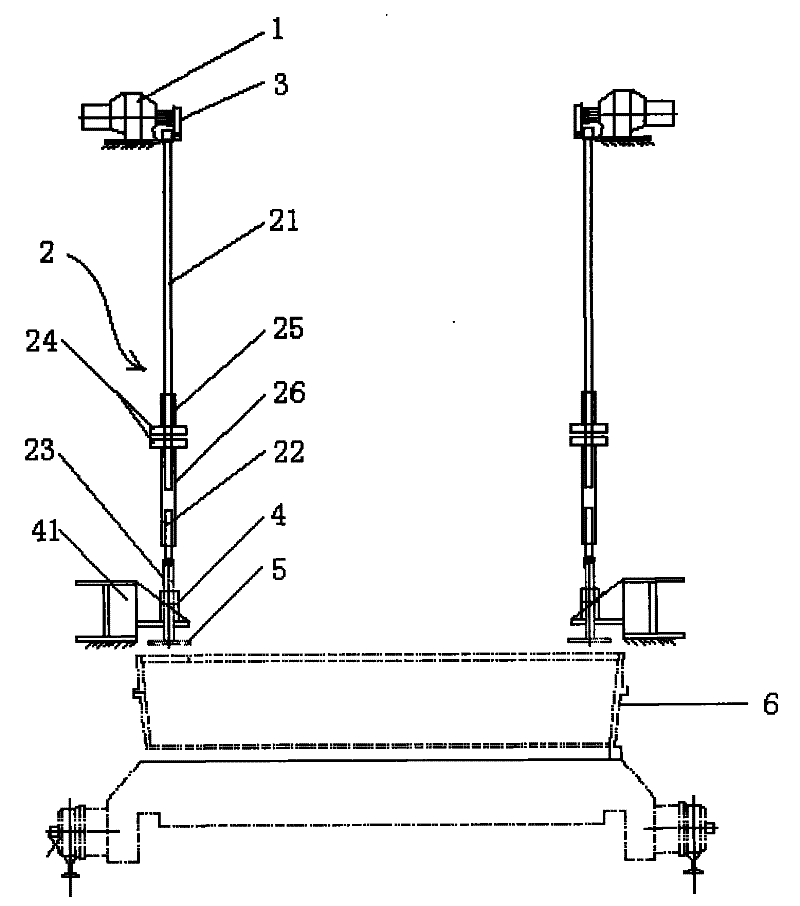

[0029] Such as figure 1 As shown, a sintering machine trolley edge material pressing device includes a power unit 1 (in this embodiment, the power unit adopts a reducer) and a pressing rod 2 . The output shaft of the power device 1 is provided with an eccentric wheel 3 , and the pressing rod 2 includes a first pressing rod 21 , a second pressing rod 22 , and a sliding guide rod 23 . The upper end of the first pressing rod 21 is provided with a bearing seat, and its shaft is fixedly connected to the distal end of the eccentric wheel 1 .

[0030] still as figure 1 As shown, the lower end of the first compression rod 21 and the connecting end of the second compression rod 22 are provided with a height adjustment device, and the lower end of the second compression rod 22 is connected to the sliding guide rod 23 through a bearing, and the lower end of the sliding guide rod 23 passes through The guide device 4 is provided with a pressure plate 5 .

[0031] The height adjustment d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com