Redundancy control method for selecting and switch-interlocking work modes of billet casting machine

A working method, billet continuous casting technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as no research reports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] figure 1 It shows the electrical path for controlling the redundant control method for selecting the working mode of the billet continuous casting machine and switching interlocking, including a universal transfer switch (2), a programmable control device (1) and a monitoring man-machine interface (3).

[0035] The universal transfer switch (2) is used as the control input of "hard switching" in the redundant control method of the selection of the billet continuous casting machine's working mode and switching interlocking, and it is necessary to ensure that the "disconnect", "manual", " The order of the five working mode bits and remote control bits of "send dummy", "casting preparation" and "pouring" cannot be changed.

[0036] The programmable control device (1) realizes the interlocking control of the redundant control method of selecting the working mode of the billet continuous casting machine and switching interlocking.

[0037] The monitoring man-machine interfa...

Embodiment 2

[0039] (1) Collect the state signal of the universal transfer switch (2) and store it in I01.

[0040] Correspondence table between variable I01 and control bit of universal transfer switch

[0041] address number

Way of working

state

I01.0

disconnect

0 / 1

I01.1

manual

0 / 1

I01.2

Dummy ingot

0 / 1

I01.3

ready to cast

0 / 1

I01.4

casting

0 / 1

I01.5

0 / 1

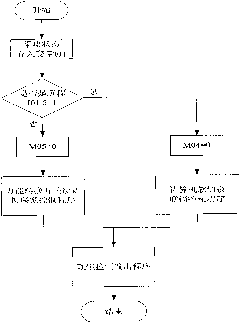

[0042] (2) Determine whether it is "remote control".

[0043] If I01.5=1 means "remote control", enter the computer (HMI) soft switching interlocking control program.

[0044]If I01.5=0 is not "remote control", enter the hard switching interlocking control program of the universal transfer switch.

[0045] (3) The outputs of the two interlocking control programs are fused to form one output.

Embodiment 3

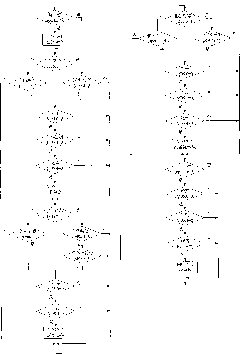

[0047] (1) Establish an analog variable operate on the computer monitoring man-machine interface. Establish correspondence between the five working modes of the billet continuous casting machine and the variable operate, and realize the positioning of the five working modes of "disconnect", "manual", "send dummy ingot", "casting preparation" and "pouring". Functions whose order cannot be changed, realize operation and display on the monitoring man-machine interface at the same time.

[0048] Correspondence table between the variable operate and the five working modes in the monitoring man-machine interface

[0049] address number

Way of working

state

operate

disconnect

operate=1

operate

manual

operate=2

operate

Dummy ingot

operate=3

operate

ready to cast

operate=4

operate

casting

operate=5

[0050] (2) if image 3 The interlocking control flow shown realizes the upward selectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com