Vision inspection apparatus

A visual inspection and instrument technology, applied in the field of visual inspection instruments, can solve problems such as the inability to perform visual inspection smoothly, reduce the reliability of visual inspection, and fail to measure accurate images, so as to achieve smooth visual inspection, increase productivity, and enhance reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

[0051] Next, the vision inspection apparatus according to the present invention will be explained in detail with reference to the accompanying drawings.

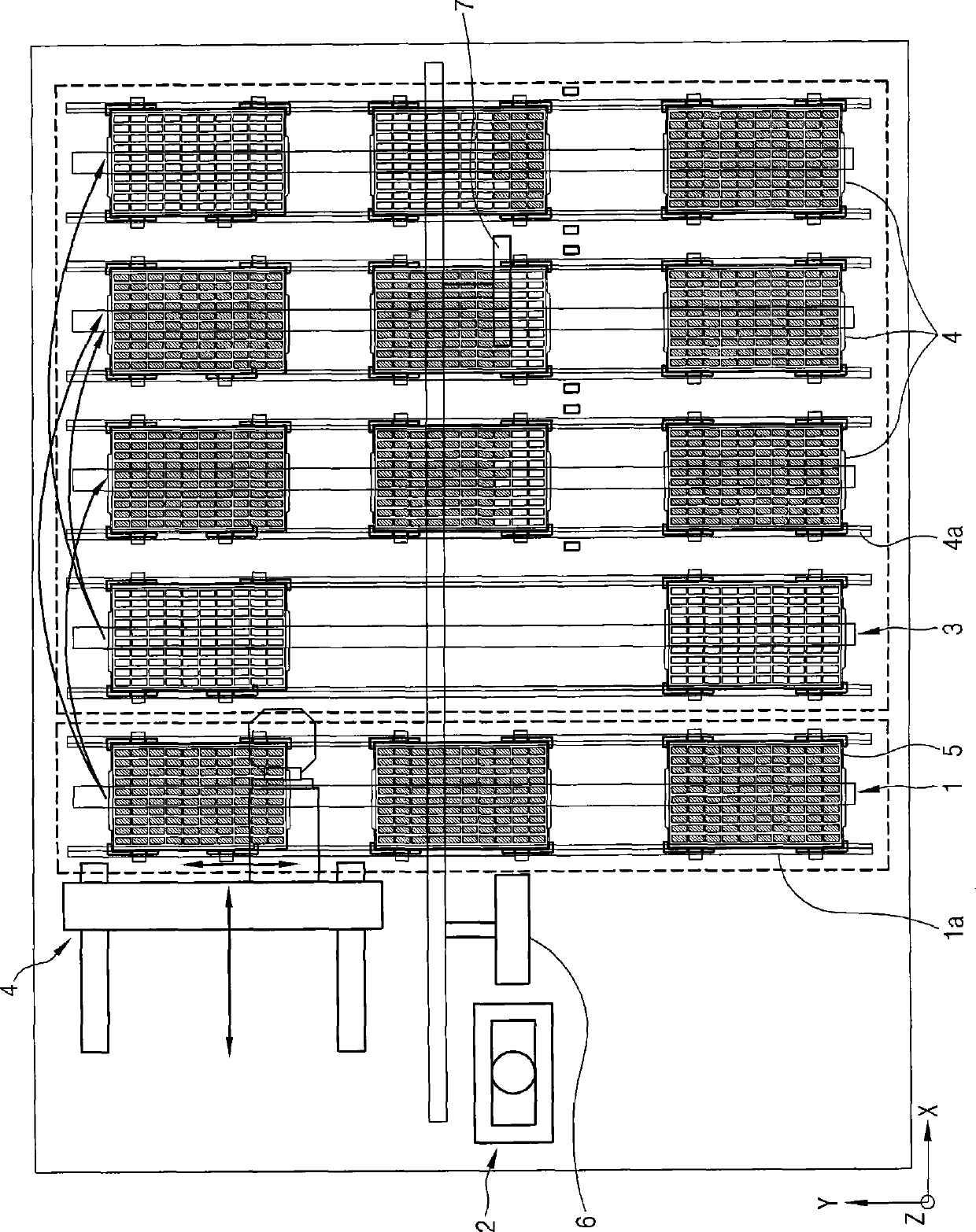

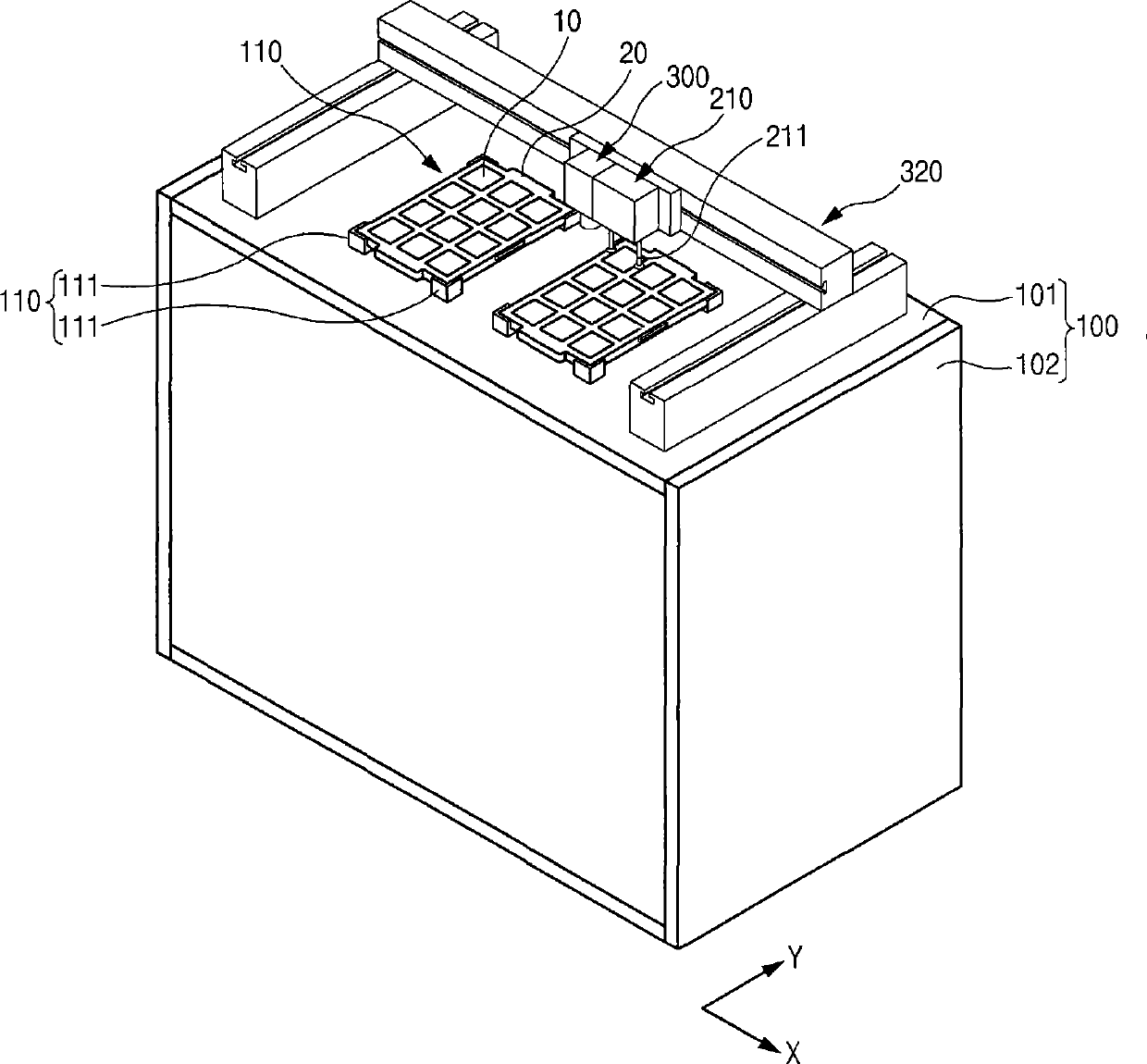

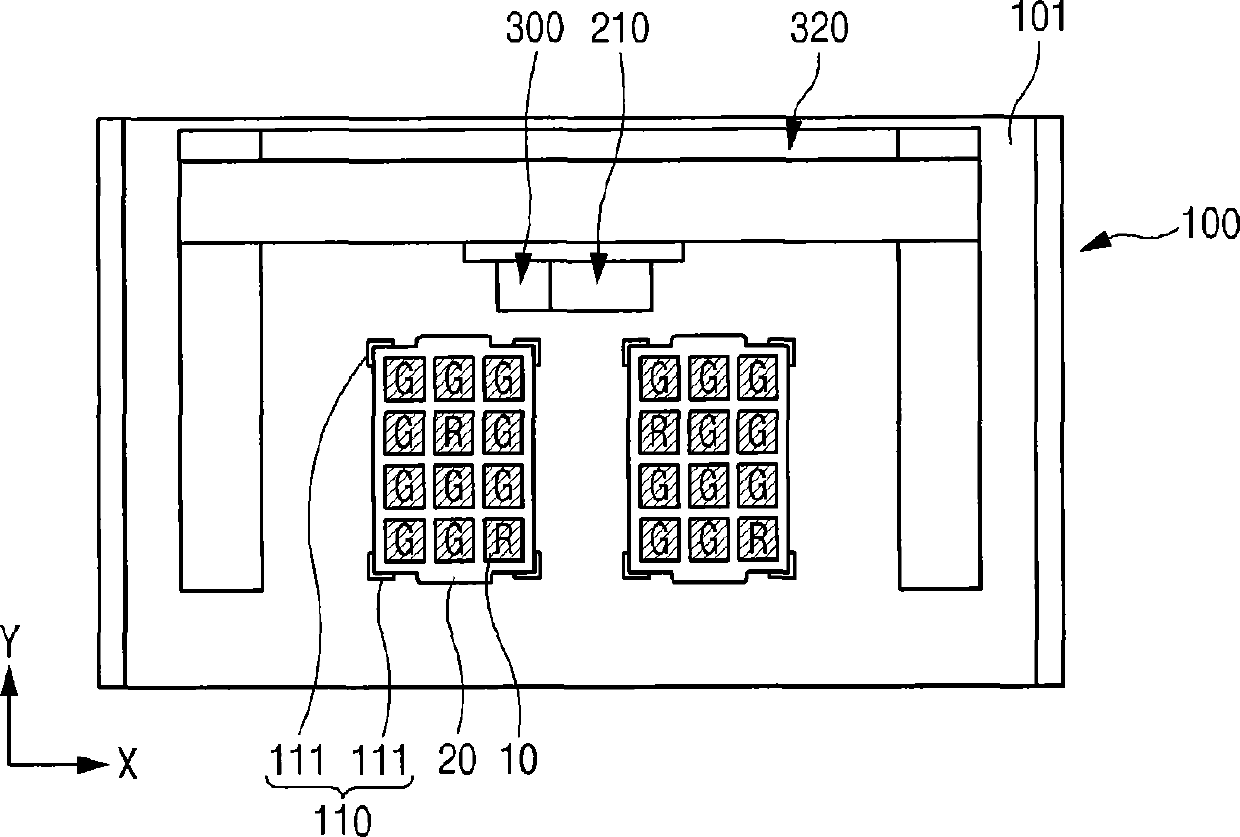

[0052] figure 2 is a perspective view of the visual inspection instrument according to the first embodiment of the present invention, and Figures 3A-3C for showing figure 2 A plan view of the operation of the visual inspection instrument in .

[0053] Such as figure 2 As shown in , the visual inspection instrument according to the first embodiment of the present invention includes: a body 100; two or more trays 20 mounted on a tray installation unit 110 and loaded with electronic components 10 thereon for visual inspection, The tray installation unit 110 is fixedly installed in the body 100; the visual inspection unit 300 is used to visually inspect the electronic components 10 loaded in the tray 20; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com