Aromatic polyamide nanofiber and fiber structure containing the same

一种芳族聚酰胺、纳米纤维的技术,应用在单组分聚酰胺人造长丝、单组分共聚多酰胺人造长丝、纳米技术等方向,能够解决难以适用、电纺丝难以均一叠层收集器等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The aromatic polyamide polymer of the present invention is produced by the interfacial polymerization method based on the method described in JP-A-47-10863 as follows.

[0063] 25.13 g (99 mol%) of isophthaloyl chloride and 0.25 g (1 mol%) of terephthaloyl chloride were dissolved in 125 ml of tetrahydrofuran with a water content of 2 mg / 100 ml, and cooled to -25°C. While stirring, a solution obtained by dissolving 13.52 g (100 mol%) of m-phenylenediamine in 125 ml of the aforementioned tetrahydrofuran was added as a thin stream over about 15 minutes to prepare a white emulsion (A). Separately, 13.25 g of anhydrous sodium carbonate was dissolved in 250 ml of water at room temperature, and cooled to 5° C. while stirring to precipitate sodium carbonate hydrate crystals to prepare a dispersion (B). The above emulsion (A) and dispersion (B) were vigorously mixed. After mixing was continued for another 2 minutes, 200 ml of water was added for dilution and the resulting polym...

Embodiment 2~5

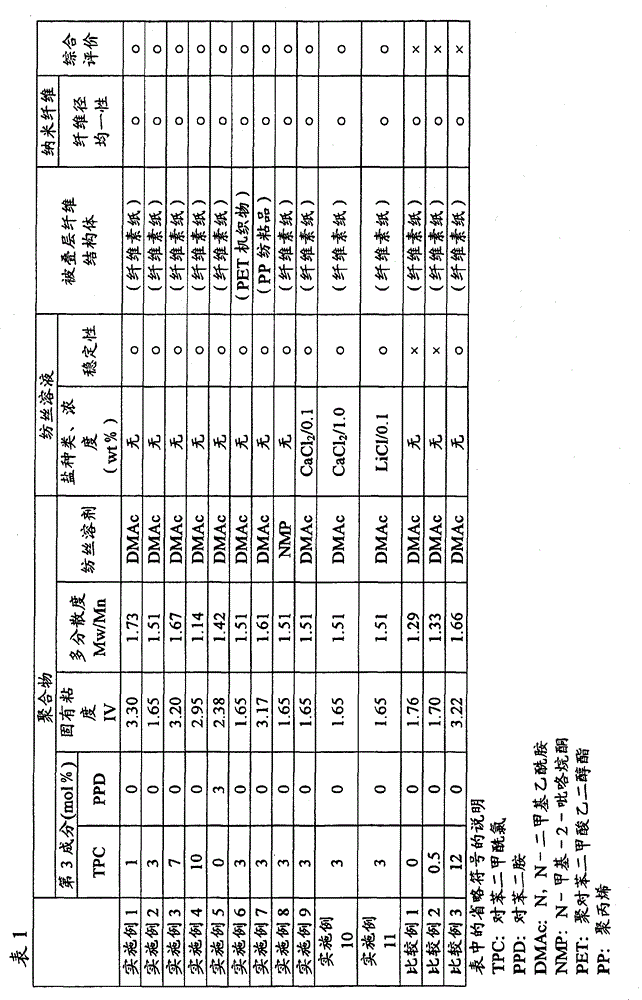

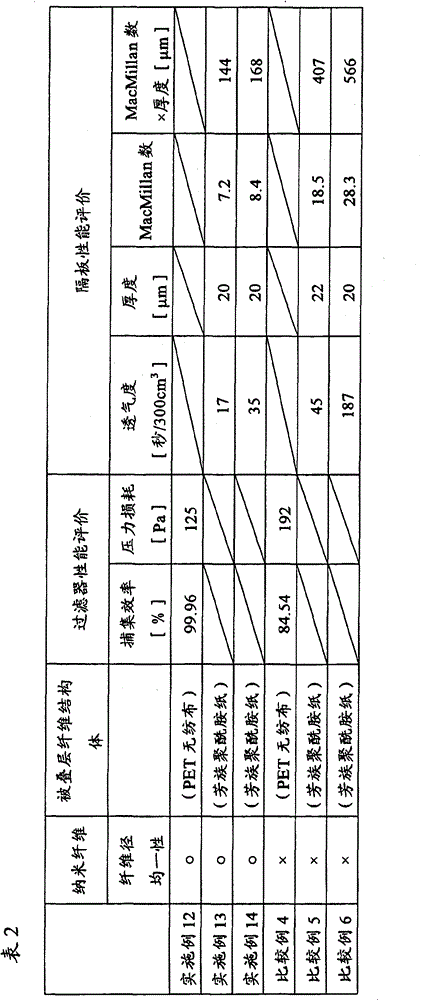

[0067] In the same manufacturing method as in Example 1, the same operations as in Example 1 were performed except that the addition rate of the third component was changed as described in Table 1. The results are shown in Table 1.

Embodiment 6、7

[0069] According to the same production method as in Example 1, except that the addition rate of terephthaloyl dichloride and the laminated fiber structure (laminated fiber structure) were changed as described in Table 1, proceed and implement Example 1 is the same operation. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com