Tea leaf extracting cup

A tea and extraction technology, applied in the field of cups, can solve the problems of limited practicality, increased inconvenience, high cost of production process and high cost of production materials, and achieve the effect of sealing the bottom and increasing the compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

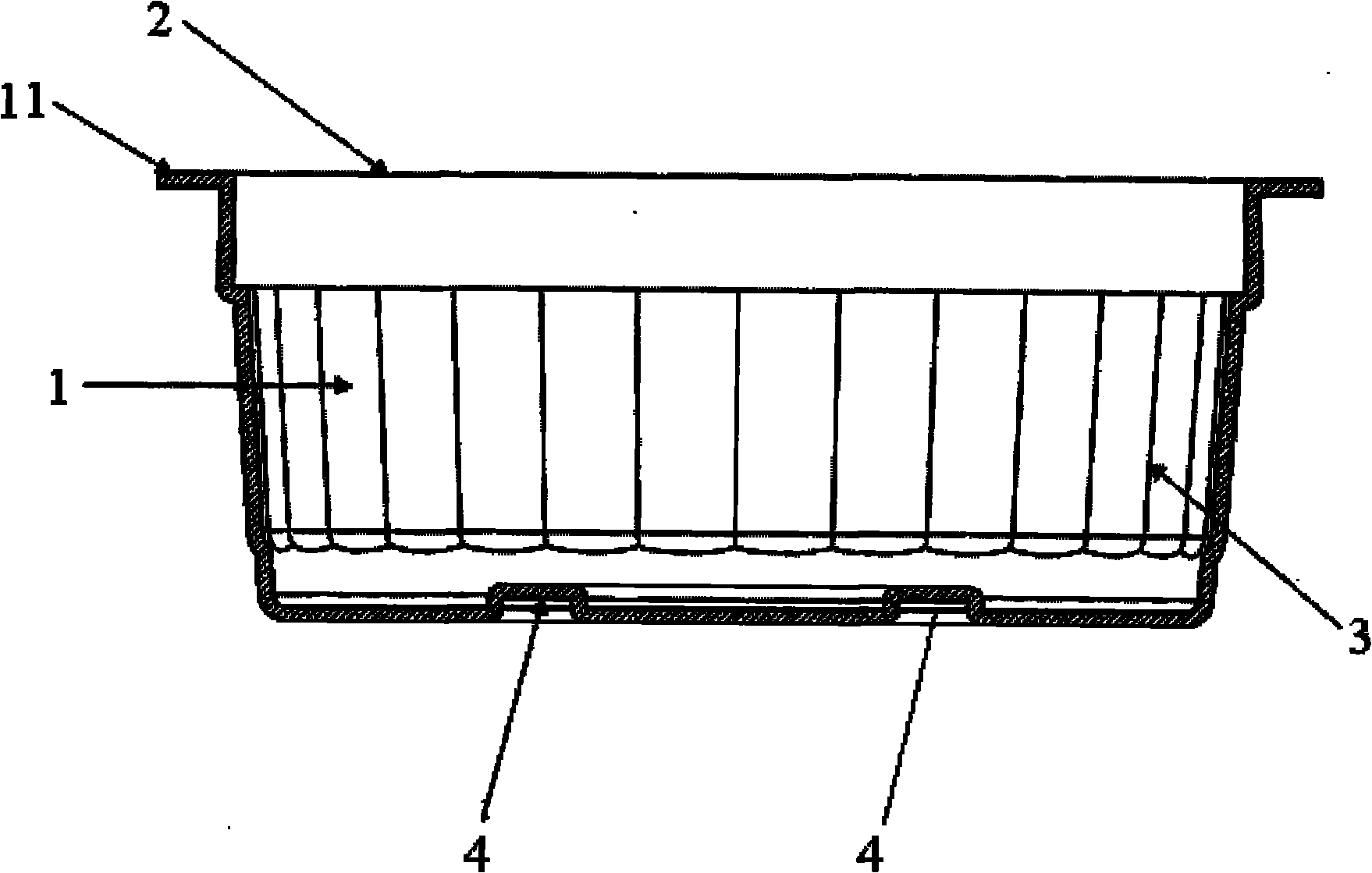

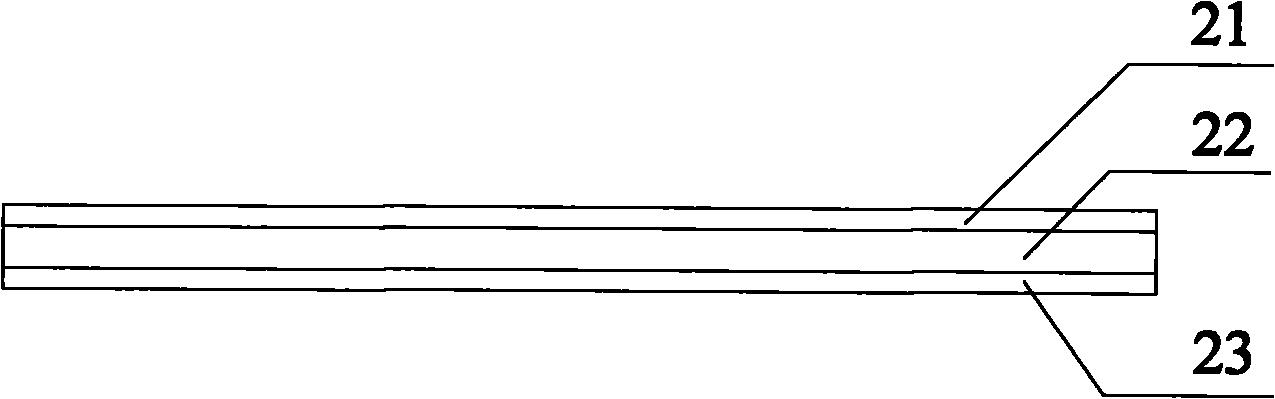

[0025] A kind of tea extraction cup, its structure is as follows figure 1 As shown, the tea extraction cup is composed of a cup body 1 and a sealing cover 2. The side wall of the cup body 1 is provided with undulating ribs 3. During the brewing and water injection process, it cooperates with the brewing system to maximize the efficiency of water injection and stirring. Speeds up the extraction of tea leaves. The bottom of the cup body 1 is provided with a protruding ring 4 to increase the pressure resistance of the bottom and ensure the sealing with the brewing system. The sealing cover 2 is covered on the circular cup rim at the top of the cup body 1 . The cup body 1 is made of polypropylene material. Sealing cap 2 is the sealing film of multilayer co-extrusion, and this sealing film has three layers, as figure 2 shown. The uppermost layer is a polyethylene terephthalate film 21 , the middle layer is an aluminum film 22 , and the lowermost layer is made of the same plast...

Embodiment 2

[0027] A tea extraction cup. The tea extraction cup is composed of a cup body and a sealing cover. The side wall of the cup body is provided with undulating ribs. During the process of brewing and water injection, it cooperates with the brewing system to maximize the efficiency of water injection and stirring, and speed up Extraction of tea leaves. The bottom of the cup is provided with a protruding ring to increase the pressure resistance of the bottom and ensure the seal with the brewing system. The sealing cover is covered on the circular cup rim at the top of the cup body. The cup body is made of polypropylene plastic material. The sealing cover is a multi-layer co-extruded sealing film. The sealing film has three layers. The uppermost layer is a polyethylene terephthalate film, the middle layer is an aluminum film, and the lowermost layer is made of the same plastic film as the cup body. An identification mark is printed on the sealing cap, and the identification mark i...

Embodiment 3

[0029] A tea extraction cup. The tea extraction cup is composed of a cup body and a sealing cover. The side wall of the cup body is provided with undulating ribs. During the process of brewing and water injection, it cooperates with the brewing system to maximize the efficiency of water injection and stirring, and speed up Extraction of tea leaves. The bottom of the cup is provided with a concave ring to increase the pressure resistance of the bottom and ensure the seal with the brewing system. The sealing cover is covered on the circular cup rim at the top of the cup body. The cup body is made of polypropylene plastic material. The sealing cover is a multi-layer co-extruded sealing film. The sealing film has three layers. The uppermost layer is a polyethylene terephthalate film, the middle layer is an aluminum film, and the lowermost layer is made of the same plastic film as the cup body. An identification mark is printed on the closure cap, which is a bar code to identify ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com