Electrode wire diameter on-line automatic detection and compensation system during linear cutting

An automatic detection and compensation system technology, applied in electric processing equipment, measuring/indicating equipment, other manufacturing equipment/tools, etc., can solve the problems of automatic input compensation cutting, complicated debugging, inconvenient implementation, etc., and achieve data processing. The method is practical, realizes automatic compensation, and saves human and financial resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

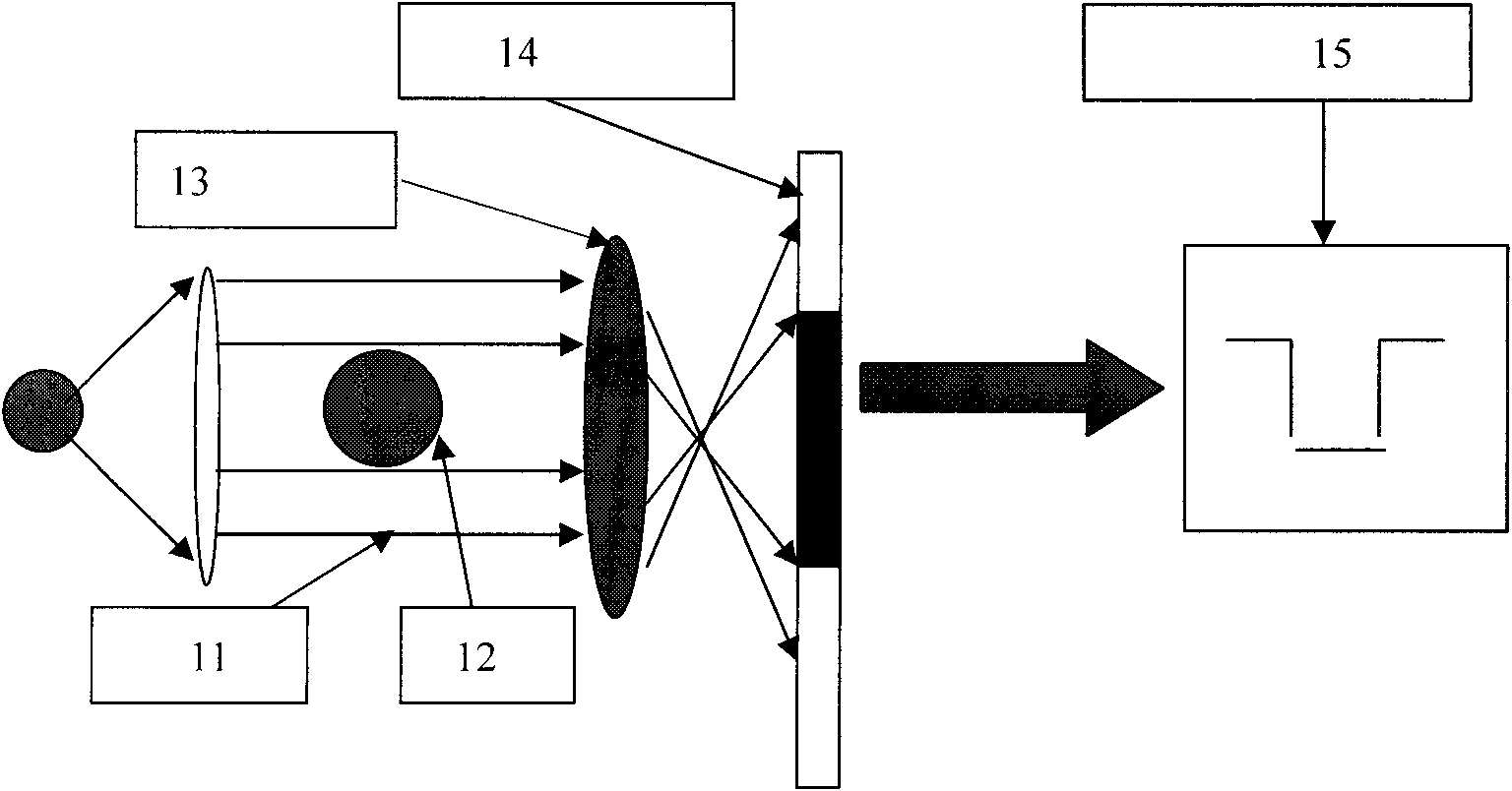

Image

Examples

Embodiment Construction

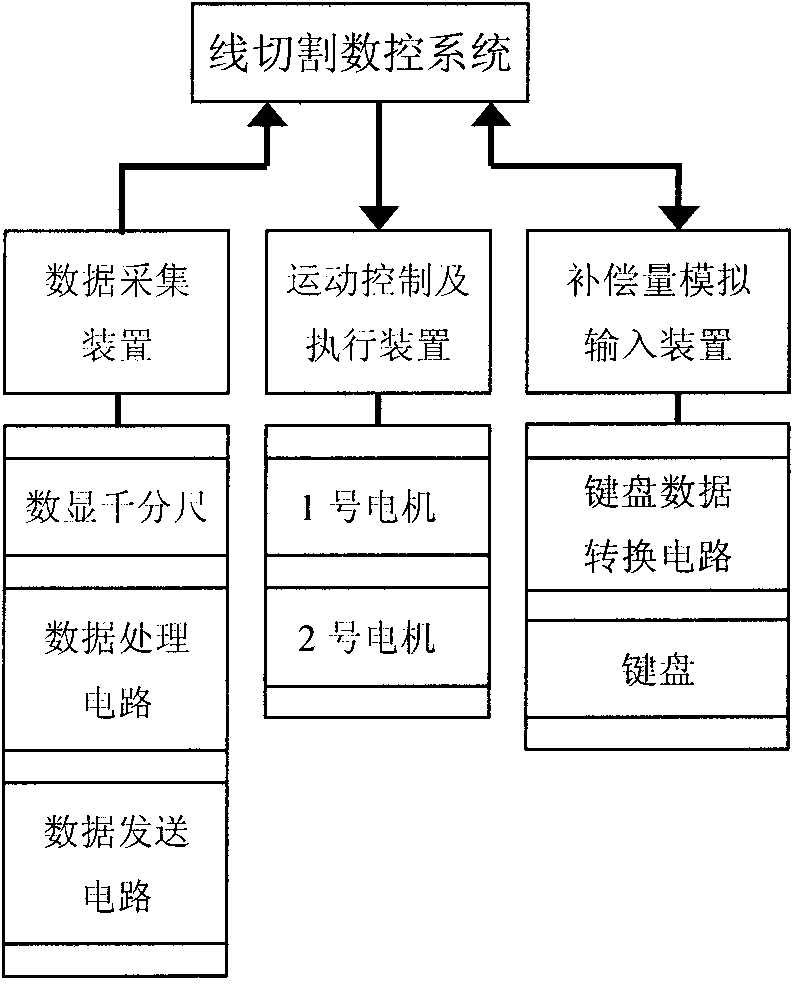

[0029] Such as figure 2 Shown is the control schematic diagram of the online automatic detection and compensation system of the electrode wire. The electrode wire online automatic detection and compensation system mainly includes a data acquisition device, a motion control and execution device, an error amount analog input device and a wire cutting numerical control system. The motion control and execution device sends the data acquisition device into the test point for 8 to 10 measurements to obtain the average value, and then compares the average value with the initial diameter of the electrode wire to obtain the compensation amount, and then inputs the compensation amount through the error amount analog The keyboard data conversion circuit in the device is converted into keyboard signals and fed back to the wire cutting numerical control system, and the wire cutting numerical control system re-controls the wire cutting machine tool to perform compensation cutting.

[0030...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com