Indirect speed reducing device of transmission system of electric automobile

A transmission system and deceleration device technology, applied in control devices, vehicle components, transportation and packaging, etc., can solve problems affecting the normal operation efficiency and service life of motors, high requirements for concentric butt joint accuracy, increased friction and noise, etc. Achieve the ability to increase charging endurance, reduce the influence of conduction and magnetic field density, and increase the driving force and traction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

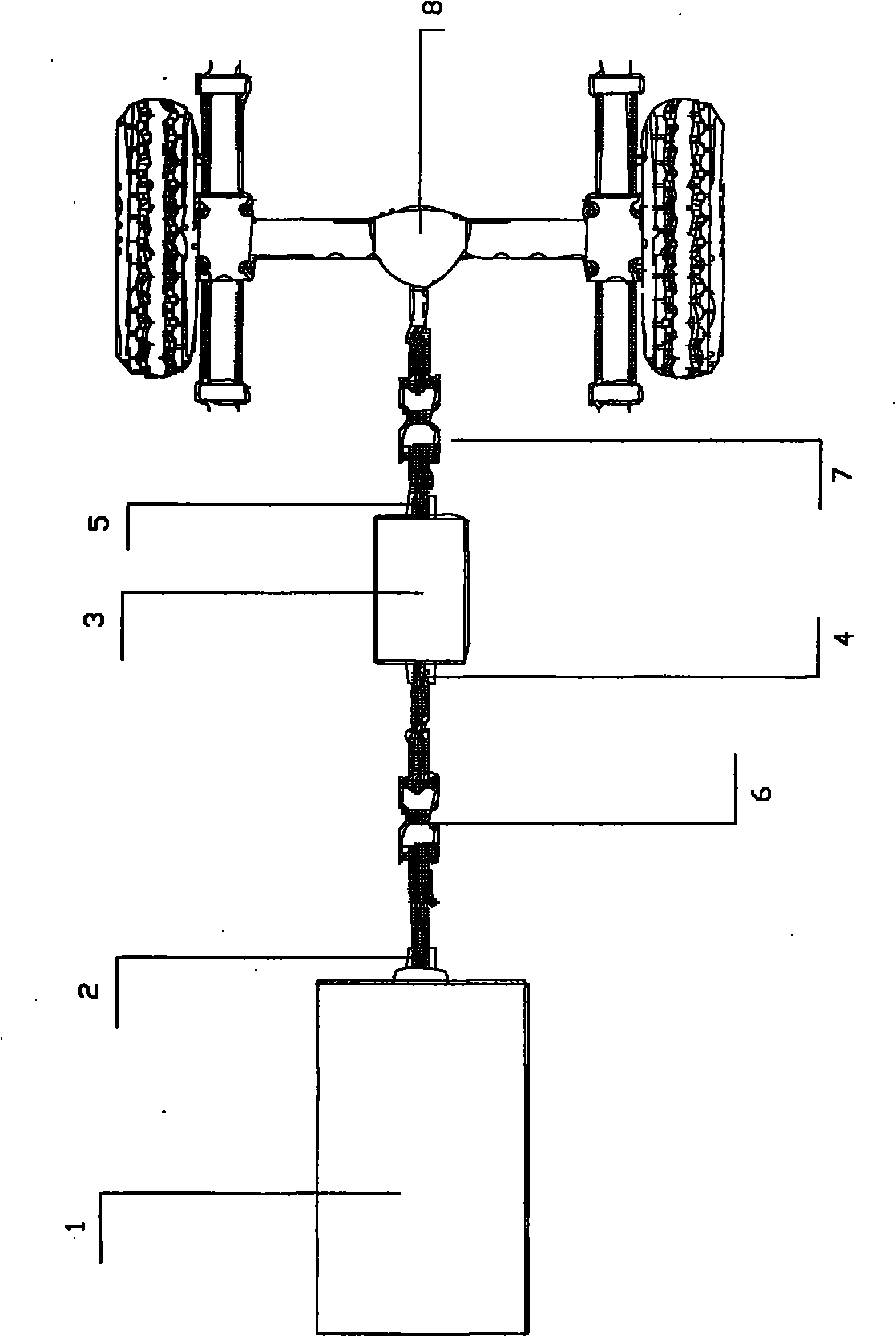

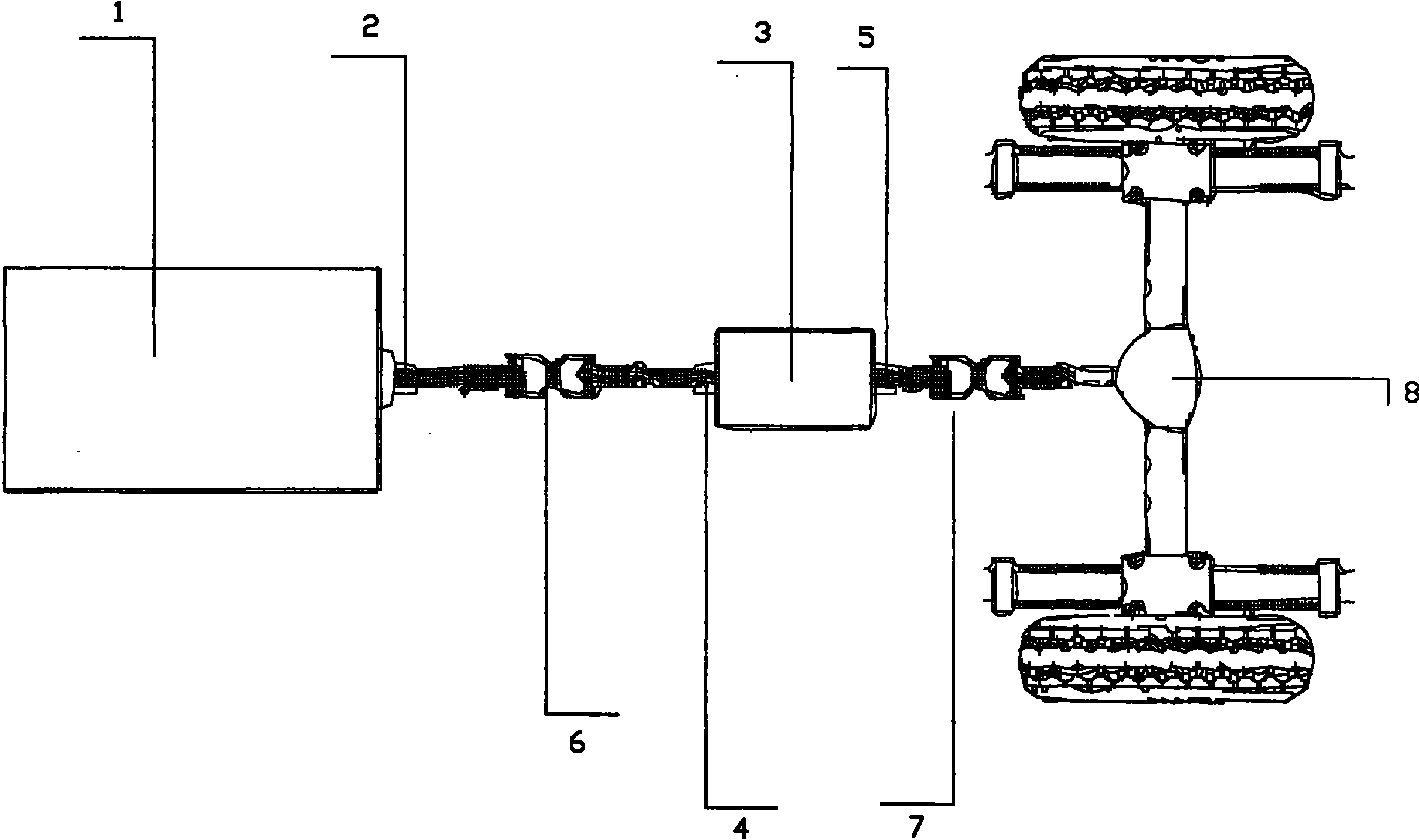

[0012] Such as figure 1 As shown: the present invention mainly includes: motor 1, motor output shaft 2, reducer 3, reducer input shaft 4, reducer output shaft 5, first universal joint 6, second universal joint 7, drive axle 8 . A first universal joint 6 is arranged between the motor 1 and the reducer 3 , so that the motor 1 and the reducer 3 are connected through the first universal joint 6 . The specific embodiment is that the output shaft 2 of the motor 1 is connected with one end of the first universal joint 6, and the input shaft 4 of the reducer is connected with the other end of the first universal joint 6; the output shaft 5 of the reducer 3 is connected with the second universal joint 6. One end of the joint 7 is connected, and the other end of the second universal joint 7 is connected with the drive axle 8 .

[0013] The above descriptions are only preferred embodiments of the present invention, and do not limit the present invention in any form. Although the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com