Silver-nickel-based electrical contact material and preparation method thereof

An electric contact material, silver-nickel-based technology, applied in the field of powder metallurgy, can solve the problems of reduced electrical life and breaking capacity, poor resistance to arc burning, and oxidation of contact materials, and achieves improved welding resistance and anti-corrosion resistance. High weldability and burnout resistance, weak oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

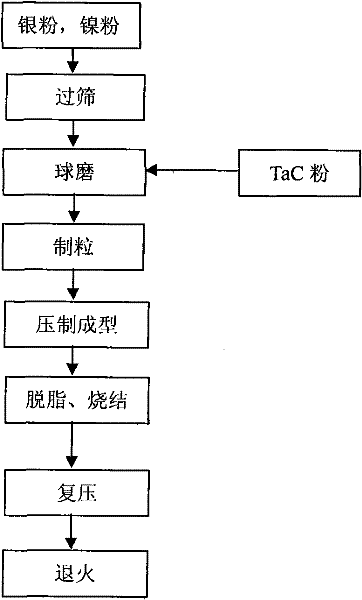

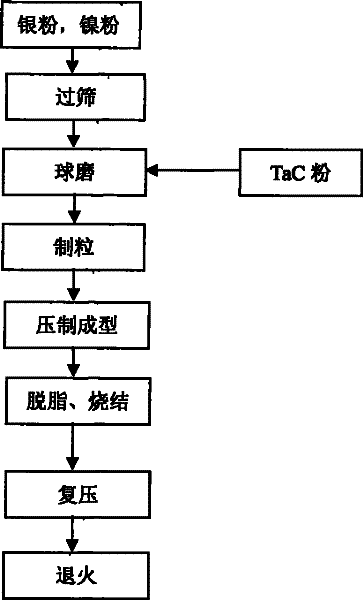

[0025] (1) first 69.9wt% Ag powder and 30wt% Ni powder are passed through a 200 mesh sieve; the Ni powder in this embodiment is reduced nickel powder, one is to remove oxides on the powder surface; the other is to reduce the moisture content in the powder ; The third is to improve the surface activity of the powder;

[0026] (2) Mix and ball mill with 0.1wt% TaC (1-2 μm) powder afterwards;

[0027] (3) Then add the binder to the ball-milled powder, and sieve and granulate:

[0028] (4) Molding the granulated powder on a hydraulic press with a pressure of 400MPa;

[0029] (5) Degreasing and sintering the green compact under a hydrogen atmosphere, the debinding temperature is 320°C, and it is kept for 1h, and then the temperature is raised to 900°C for 5h;

[0030] (6) The sintered green body is repressed on the hydraulic press again, and the pressing pressure is 600MPa;

[0031] (7) Annealing the repressed product under a hydrogen protective atmosphere, the annealing tempera...

Embodiment 2

[0036] (1) at first 65wt% Ag powder and 30wt% Ni powder are crossed 200 mesh sieves;

[0037] (2) Mix ball milling with 5wt% TaC (1~2μm) powder afterwards;

[0038] (3) Then add the binder to the ball-milled powder, and sieve and granulate:

[0039] (4) Molding the granulated powder on a hydraulic press with a pressure of 400MPa;

[0040] (5) Degreasing and sintering the green compact under a hydrogen atmosphere, the debinding temperature is 320°C, and it is kept for 1h, and then the temperature is raised to 900°C for 5h;

[0041] (6) The sintered green body is repressed on the hydraulic press again, and the pressing pressure is 600MPa;

[0042] (7) Annealing the repressed product under a hydrogen protective atmosphere, the annealing temperature is 600°C, and the time is 3h;

[0043] (8) The annealed green body is then repressed for the second time on a hydraulic press, and the pressing pressure is 1400MPa.

[0044] After testing, the density of the AgNi-based electrical c...

Embodiment 3

[0046] (1) at first 67wt% Ag powder and 30wt% Ni powder are crossed 200 mesh sieves;

[0047] (2) Mix ball milling with 3wt%wtTaC (1~2μm) powder afterwards;

[0048] (3) Then add the binder to the ball-milled powder, and sieve and granulate:

[0049] (4) Molding the granulated powder on a hydraulic press with a pressure of 400MPa;

[0050] (5) Degreasing and sintering the green compact under a hydrogen atmosphere, the debinding temperature is 320°C, and it is kept for 1h, and then the temperature is raised to 900°C for 5h;

[0051] (6) The sintered green body is repressed on the hydraulic press again, and the pressing pressure is 600MPa;

[0052] (7) Annealing the repressed product under a hydrogen protective atmosphere, the annealing temperature is 600°C, and the time is 3h;

[0053] (8) The annealed green body is then repressed for the second time on a hydraulic press, and the pressing pressure is 1400MPa.

[0054] After testing, the density of the AgNi-based electrical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com