Beam spanning multilayer deck

A panel and bottom layer technology, applied in bridges, buildings, etc., can solve problems such as unfavorable full utilization, unfavorable girder height, difficulty in adapting to long-span girder bridge structures, etc., to save land resources and urban space, and improve vertical overall stability , Improve the effect of passing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

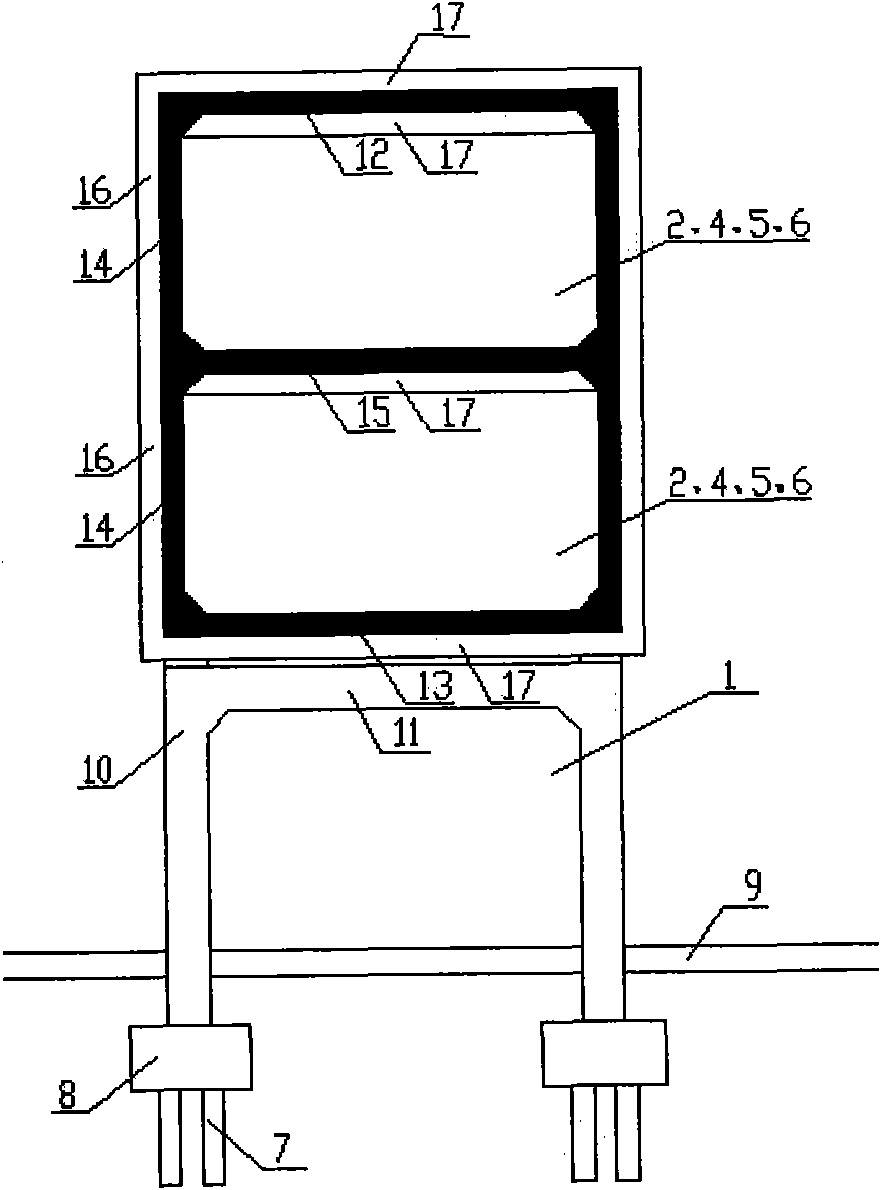

[0096] Example 1: A1-type cross-story beam with grid-shaped cross section

[0097] see figure 1 , The cross-floor beam is integrally connected by the web 14 , the upper flange 12 , the lower flange 13 and the face plate 15 . The cross section is in the shape of a "Japanese" grid, with two webs 14 on both sides in the horizontal direction, and a layer of panels 15 between the upper flange 12 and the lower flange 13, forming a horizontal single hole and a vertical two-story beam inner channel , The net width of a single hole in the channel in the beam is ≥3.5m, ≤15m. The web 14 spans the inner channel of the second floor beam. Web 14 adopts straight web. The cross-story beam adopts a simply supported beam structure, a continuous beam structure or a rigid frame structure formed with the bottom column 10 . The cross-story beam adopts prestressed reinforced concrete structure, steel structure or combined structure of prestressed reinforced concrete and steel. The web 14 is rei...

Embodiment 2

[0098] Embodiment 2: A2-type cross-story beam with grid-shaped cross section

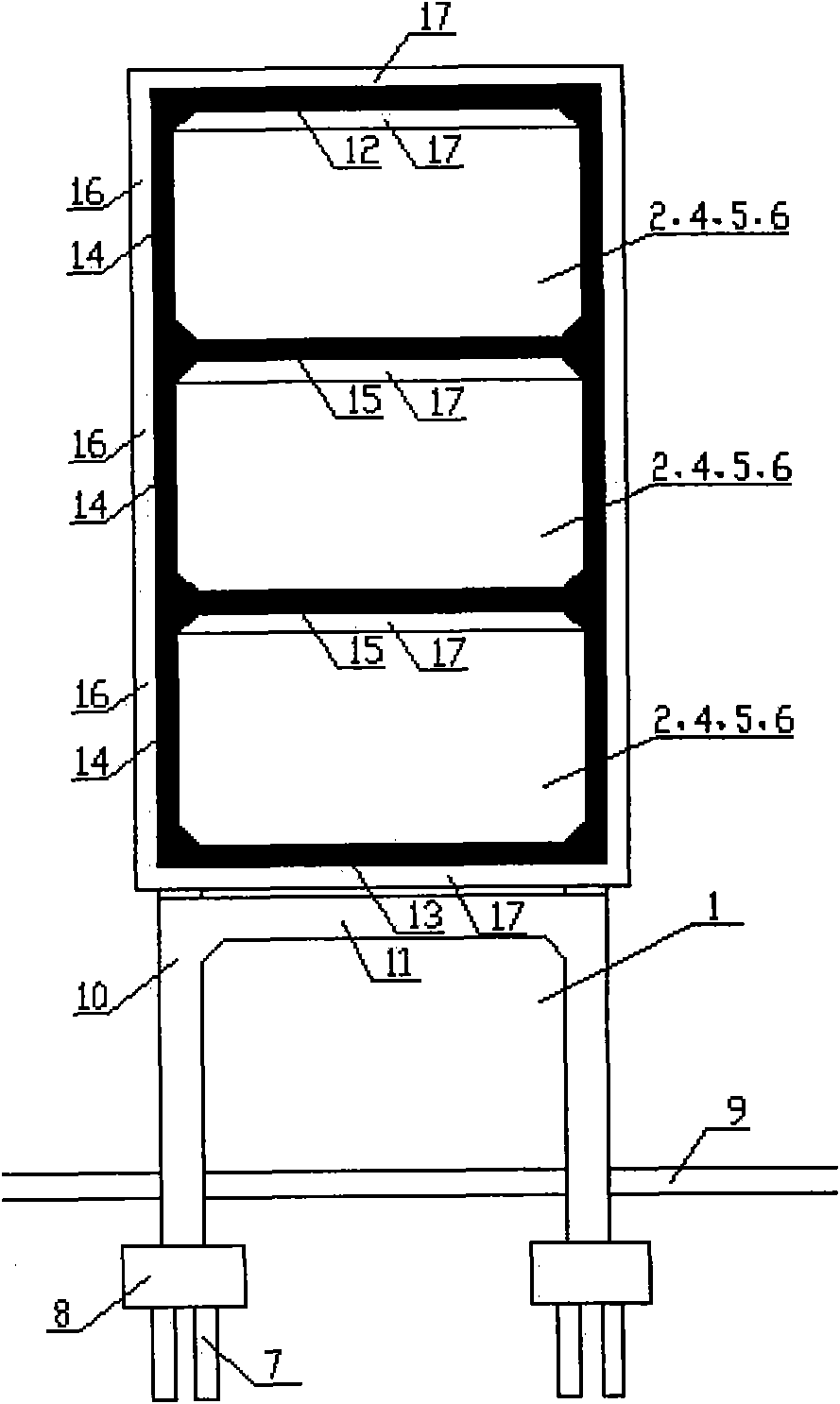

[0099] see figure 2 , A second-layer panel 15 is arranged between the upper flange 12 and the lower flange 13 to form a horizontal single hole and a vertical three-layer beam inner passage, and the web 14 spans the three-layer beam inner passage. All the other are the same as embodiment one.

Embodiment 3

[0100] Embodiment 3: A3-type cross-story beam with grid-shaped cross section

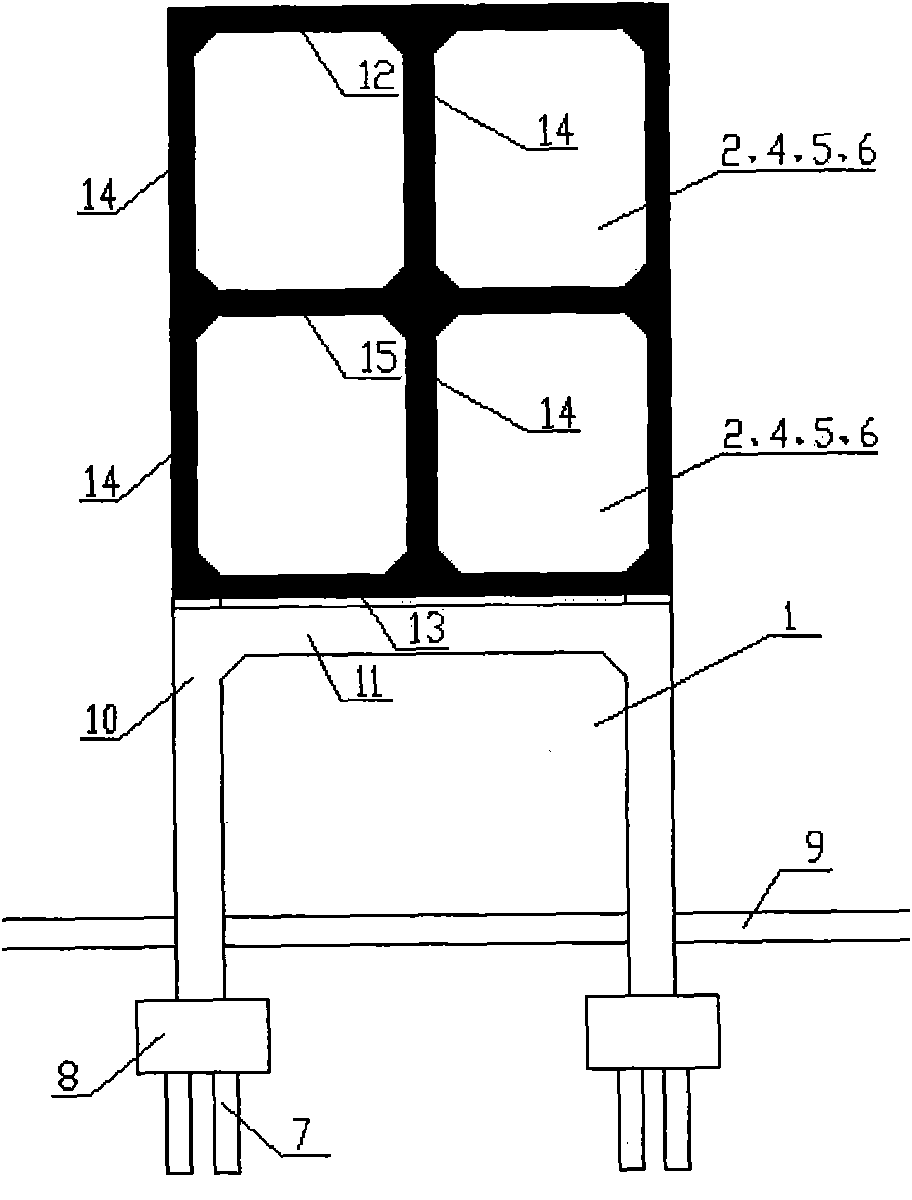

[0101] see image 3 , two webs 14 on both sides and one web 14 in the middle are arranged horizontally, and a layer of panels 15 is arranged between the upper flange 12 and the lower flange 13 to form a horizontal double hole and a vertical two-story beam inner channel, and the beam inner channel Single hole clear width ≥ 3.5m, ≤ 10m. The web 14 is not provided with ribs 16 , and the upper flange 12 , lower flange 13 and panel 15 are not provided with ribs 17 . All the other are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com