Anti-seismic combination slab for earth and rockfill dam and construction method thereof

A technology for earth-rock dams and concrete slabs, applied in dams, earthquake-proof, barrages, etc., can solve the problems of poor resistance to earthquake deformation, etc., and achieve the effects of strong deformation adaptability, good overall stability, and low project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

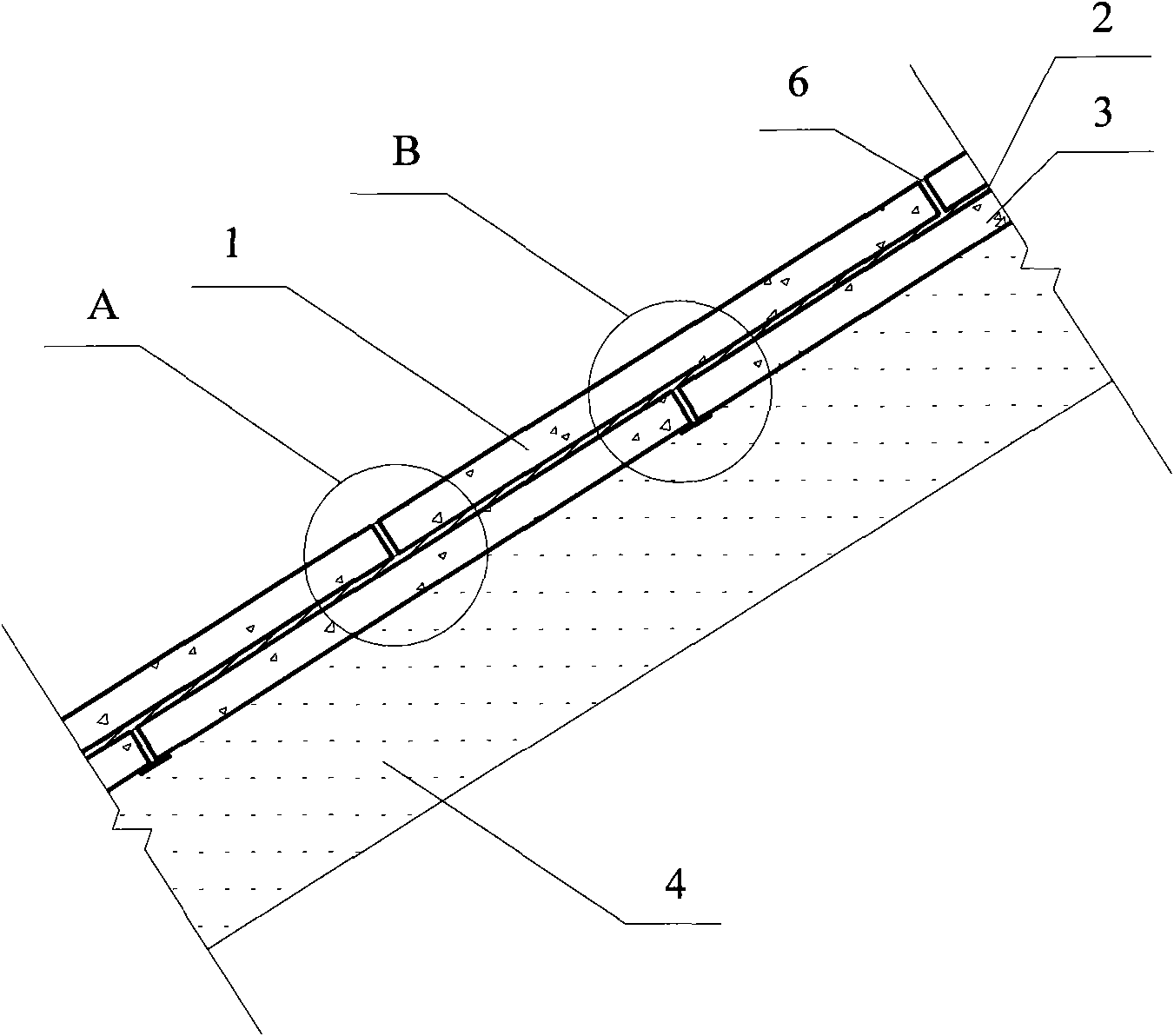

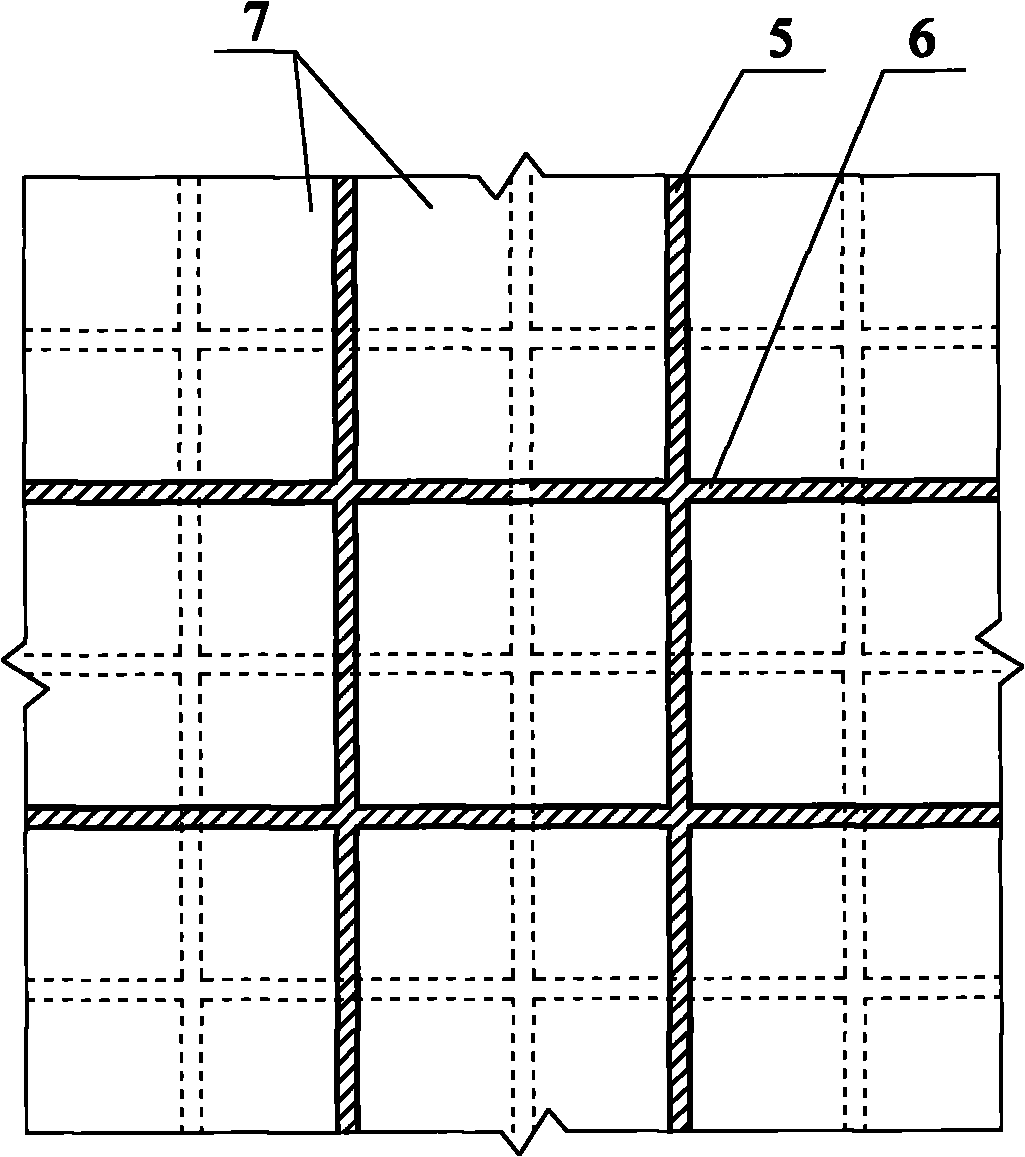

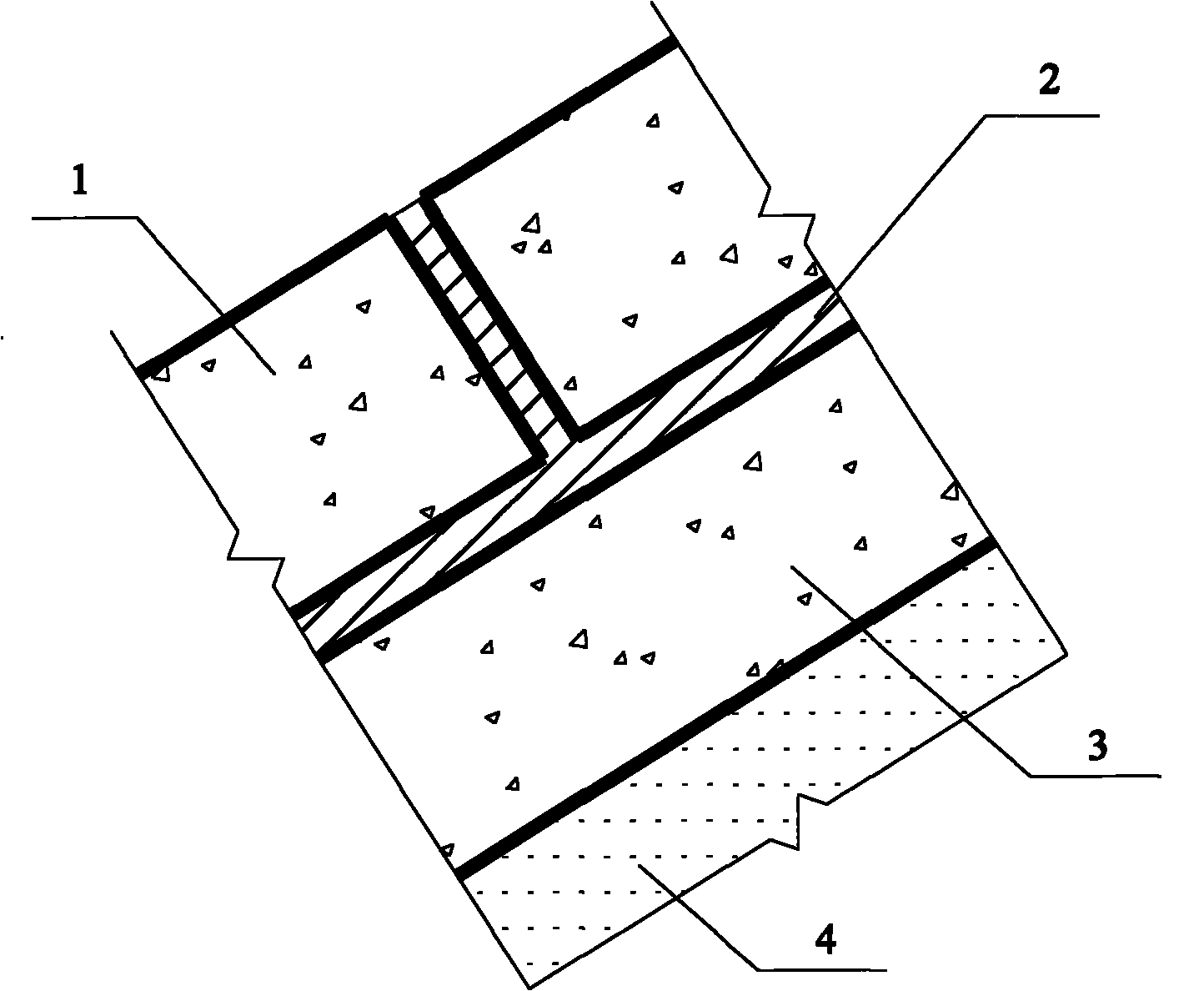

[0026] Such as Figure 1 ~ Figure 4 As shown, an anti-seismic composite panel structure of an earth-rock dam is composed of an upper concrete panel 1, an asphalt layer 2 and a lower concrete panel 3. Both the upper concrete panel 1 and the lower concrete panel 3 are composed of a plurality of rectangular concrete blocks 7, the side length of the rectangular concrete blocks 7 is 12-18m, and the thickness is 0.2-0.4m. A longitudinal split 5 and a transverse split 6 are reserved between the rectangular concrete block 7 and the rectangular concrete block 7, with a width of 1-2 cm; the space between the upper concrete panel 1 and the lower concrete panel 3 is filled with an asphalt layer 2, and the thickness of the asphalt layer is 2 cm. ~5cm; both the longitudinal splits 5 and the transverse splits 6 between the rectangular concrete blocks 7 are filled with asphalt. Each rectangular concrete block 7 of the upper concrete panel 1 and the lower concrete panel 3 adopts a staggered o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com