Integrally assembled wallboard wall and construction method thereof

An integral, wall panel technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of polluting the environment and consuming resources, and achieve the effects of good integrity, cost saving, and less ash joints.

Inactive Publication Date: 2010-09-15

黄靓

View PDF7 Cites 42 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Cast-in-place concrete structures require formwork, which consumes resources and pollutes the environment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Login to View More

Abstract

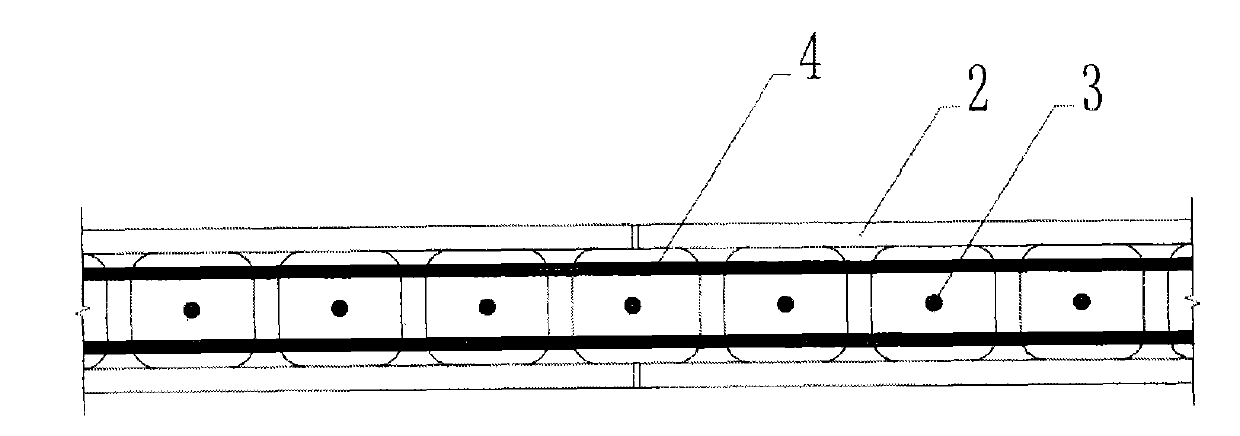

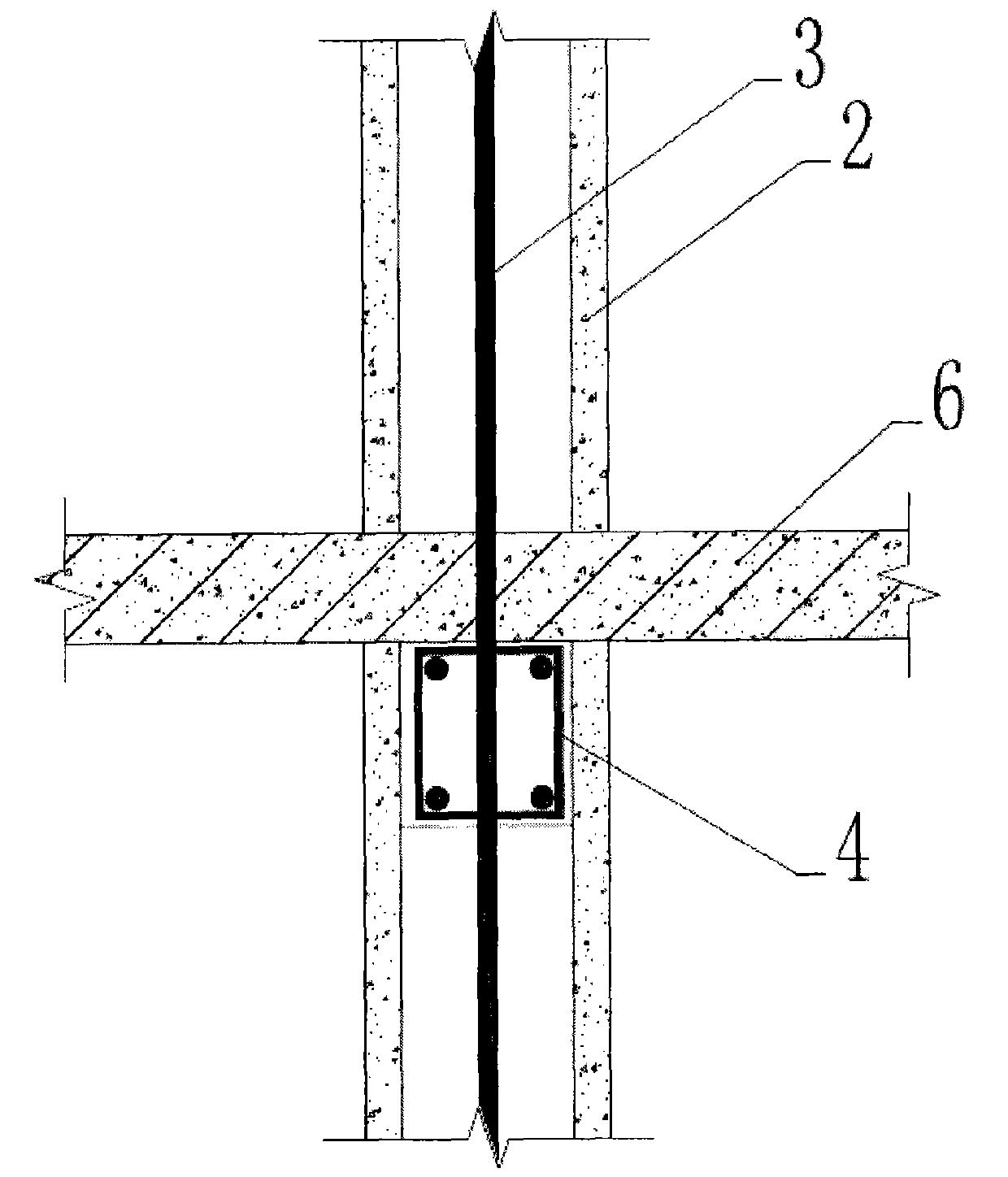

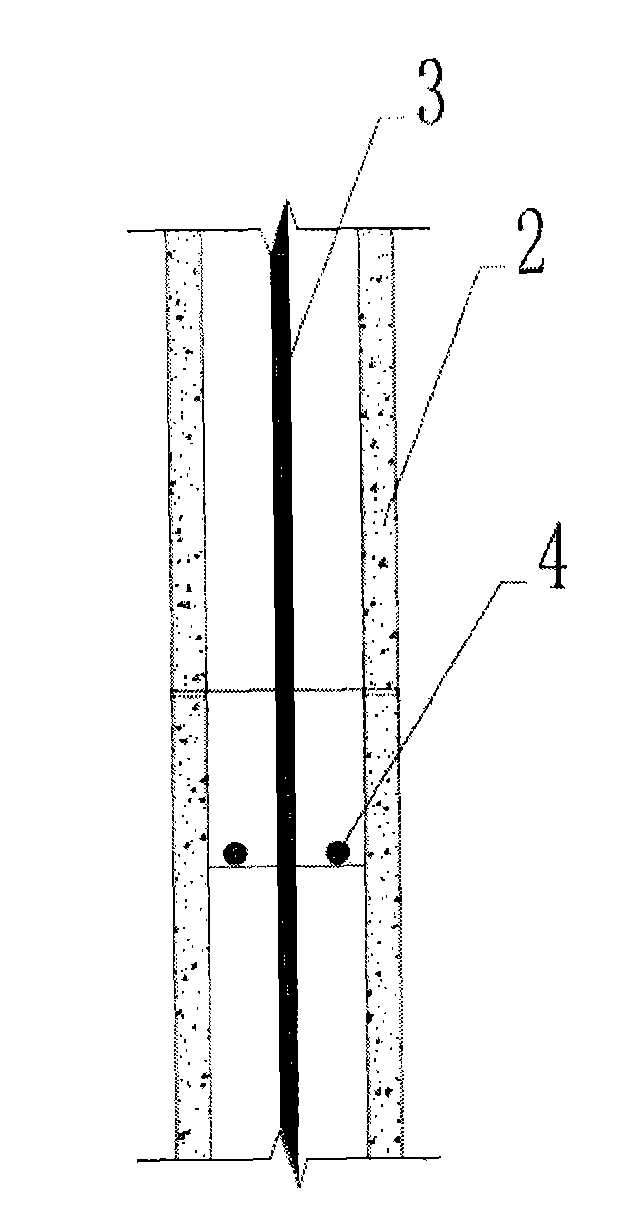

The invention discloses an integrally assembled wall and a construction method thereof. The wall consists of a prefabricated built-up wallboard (2), a horizontal reinforcing steel bar or horizontal reinforcing cage (4), a vertical reinforcing steel bar (3) and grouted concrete (5); the prefabricated built-up wallboard is 800 mm to 3000 mm in length, 400 mm to 3000 mm in height and 100 mm to 400 mm in thickness; a vertical hole (7) is arranged in the wallboard, and a horizontal groove (9) parallel to a long side is arranged on the top surface of the prefabricated built-up wallboard; the vertical reinforcing steel bars are distributed in the vertical hole of the wallboard, and the horizontal reinforcing steel bars or horizontal reinforcing cages are distributed in the prefabricated built-up block horizontal groove; the entire prefabricated wallboard is inserted into the vertical hole through an anchor bar (1) reserved on the floor or foundation, and connected with the main structure through the cast-in-place concrete. The prefabricated built-up wallboard is lifted through a small lifter in the wall construction, and the construction is fast, simple, environment-friendly and economic.

Description

technical field The invention relates to a load-bearing wall structure and a construction method thereof. Background technique With the in-depth implementation of my country's sustainable development strategy, the use of clay solid bricks has been banned in large and medium-sized cities across the country. Concrete hollow blocks as an alternative building material have become an effective alternative to solid bricks, and in concrete blocks Core-filled concrete has become a reinforced block masonry structure and has been used nationwide. Since this structure requires a lot of labor during masonry, with the continuous rise of labor costs, the cost problem will become a bottleneck in the development of reinforced block masonry structures. Cast-in-place concrete structures require formwork, which consumes resources and pollutes the environment. With the continuous improvement of our country's living standards, labor costs are also increasing. Finding a new wall structure that i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E04B2/68E04G21/14E04G21/08

Inventor 黄靓徐紫鹏吴志维李登

Owner 黄靓

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com