In-situ cast-in-place construction method for pre-tensioned pre-stressed arch-bar barn roof

A construction method and prestressing technology, applied to roofs, floors, building components, etc., can solve problems such as difficult construction, difficult quality assurance, and complicated procedures, and achieve the effect of ensuring construction quality, simple construction, and easy control of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

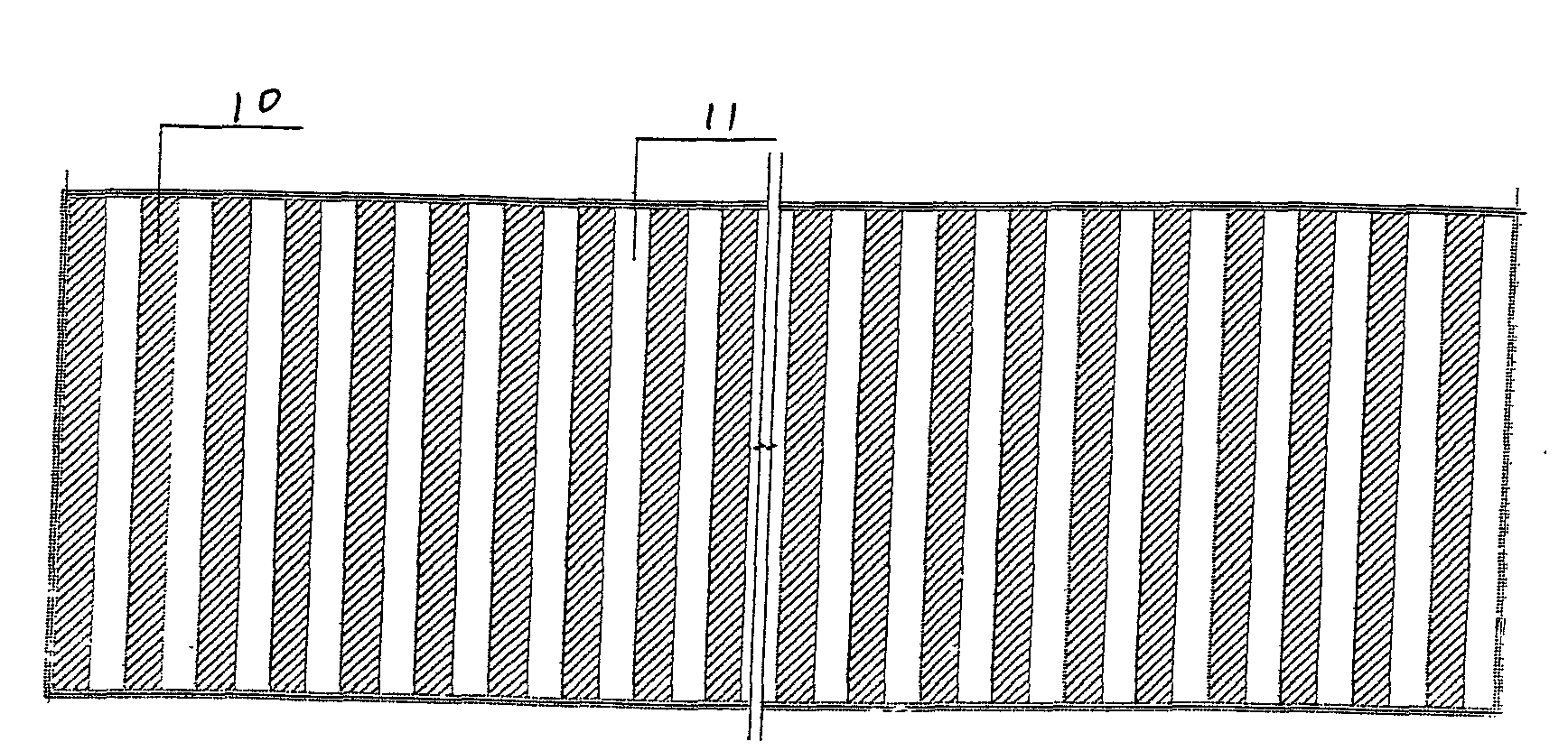

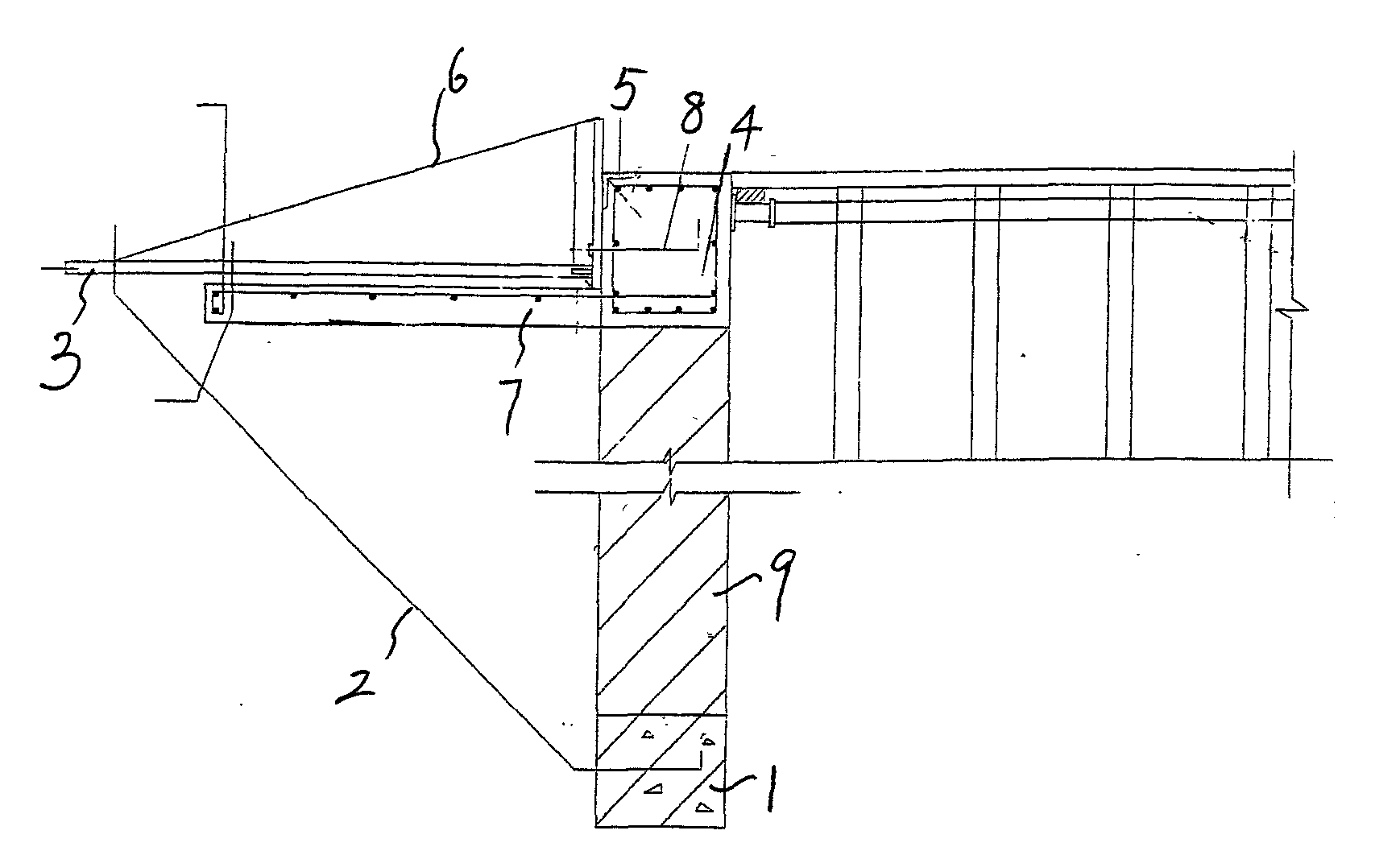

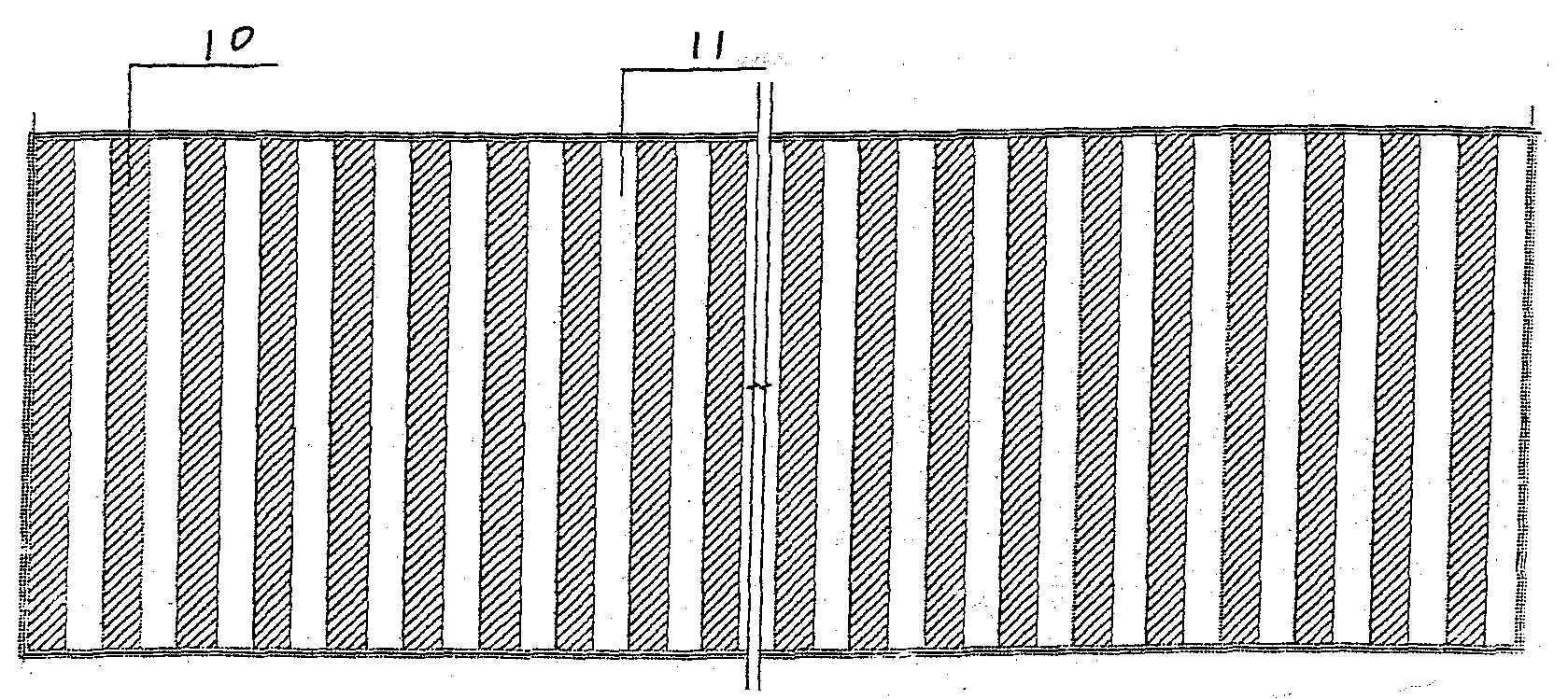

[0024] A method for in-situ cast-in-place construction of a pre-tensioned prestressed arch slab granary roof, comprising the following steps:

[0025] (1) Prefabricate the arched slab roof truss partition outside the site and carry out the concrete floor construction in the one-storey warehouse, and then carry out the wall 9 masonry and ring beam construction, and pre-embed the φ14 cable-stayed steel bar 2 and the top brace when pouring the middle ring beam 1 3 Welding, using the top ring beam 4 as a prestressed steel tensioning platform, the concrete strength of the ring beam is C40, and mixed with early strength agent (JM series or other conventional early strength agent), the dosage is 1.5% of the cement consumption; The inner stirrups of the top ring beam are densified to φ8@100, and the ∠50×5 angle steel 5 is pre-embedded at the outer upper corner of the top ring beam; when pouring the top ring beam, 6 φ22 screw rods 8 are pre-embedded according to the position of the hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com