Paper pulp pump centrifugal open impeller based on fiber suspension flow design criteria

A technology for open impellers and pulp pumps, which is applied to parts, pumps, and pump components of pumping devices for elastic fluids, and can solve problems such as lack of constraints and limited application areas, so as to improve passing capacity and hydraulic efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] Working condition: Flow Q=100(m 3 / h), lift H=20(m), speed n=1450(rev / min).

[0039] Substituting the formula to calculate the specific parameters:

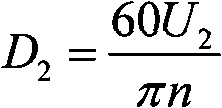

[0040] Outlet Diameter: D 2 =280(mm)

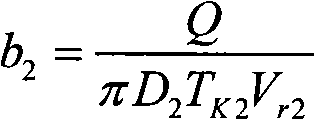

[0041] Exit Width: b 2 =35(mm)

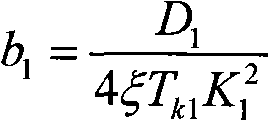

[0042] Blade inlet width: b 1 =61.4(mm)

[0043] Blade inlet diameter D 1 =97.0(mm)

[0044] Impeller inlet diameter D j =121(mm)

[0045] The inlet angles of the blades are 22°, 26.4° and 30° at the streamlines of the front disc, the middle streamline and the rear disc, respectively. The blade exit angle is 30°.

[0046] Starting from the fact that the additional stress is more prominent in the middle of the curve, it is required to constrain the relative velocity distribution across the channel to be flat, so it is better to keep the blade load distribution flat, that is, to extend the length of the blade channel appropriately. The structural parameter related to this constraint is the blade wrap angle and the equivalent expansion angle, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com